The Ultimate Guide to bread crumb maker in 2024

Introduction

Bread crumb makers are essential equipment in the food processing industry, designed to produce high-quality bread crumbs efficiently and consistently. These machines range from manual devices for small-scale operations to fully automated systems for industrial use. They are engineered to break down bread into fine or coarse crumbs, ensuring uniformity in texture and size. The use of a bread crumb maker significantly enhances productivity and maintains the quality of the final product, which is critical for both commercial and home cooking applications.

Bread crumbs are a versatile ingredient widely used in various culinary applications. They provide a crispy coating for fried foods, act as a binder in meatballs and meatloaf, and add texture to baked dishes. The consistency and quality of bread crumbs can greatly influence the texture and flavor of the final dish. Therefore, the demand for reliable and efficient bread crumb makers has grown, as they ensure the production of consistent, high-quality bread crumbs that meet the standards of professional chefs and food manufacturers.

The purpose of this guide is to provide a comprehensive overview of bread crumb makers in 2024, offering insights into their evolution, types, key features, and leading manufacturers. This guide aims to help food industry professionals, chefs, and culinary enthusiasts understand the benefits of using a bread crumb maker and make informed decisions about purchasing and maintaining these machines. By exploring the latest advancements and trends, readers will be well-equipped to optimize their bread crumb production processes, ensuring superior quality and efficiency in their culinary operations.

Types of Bread Crumb Makers

Manual Bread Crumb Makers

Manual bread crumb makers are designed for small-scale operations or home use. These devices typically require physical effort to process the bread into crumbs. They are simple to operate, affordable, and do not require electricity, making them ideal for low-volume needs. The primary advantage of manual bread crumb makers is their ease of maintenance and minimal operational costs. However, they may not be suitable for larger production requirements due to their limited capacity and manual operation.

Automatic Bread Crumb Makers

Automatic bread crumb makers are more advanced machines designed for medium to large-scale operations. These machines automate the bread crumb production process, significantly reducing the need for manual intervention. They are equipped with features such as adjustable crumb size settings, high-speed processing, and automated feeding systems. Automatic bread crumb makers offer consistent quality and high production efficiency, making them ideal for commercial kitchens and food processing plants. Their primary benefits include increased productivity, uniform crumb texture, and reduced labor costs.

Industrial vs. Home Use Bread Crumb Makers

Industrial bread crumb makers are designed for large-scale food production facilities. These machines are capable of processing large volumes of bread into crumbs quickly and efficiently. They often include advanced features such as continuous feed systems, multiple crumb size options, and robust construction to withstand heavy use. Industrial bread crumb makers are essential for manufacturers who require high output and consistent quality.

Home use bread crumb makers, on the other hand, are designed for personal or small-scale use. These machines are compact, easy to use, and suitable for producing small batches of bread crumbs. Home use models prioritize convenience and simplicity, making them accessible to non-professional users. While they may not offer the same level of efficiency or capacity as industrial models, home use bread crumb makers are perfect for everyday cooking needs.

Advantages of Bread Crumb Makers

Advantage | Description |

Efficiency and Speed | Bread crumb makersstreamline the process of producing bread crumbs, significantly reducing the time and effort required compared to manual methods. Automated systems can process large volumes quickly, making them ideal for commercial and industrial use. |

Consistency and Quality | These machines ensure uniformity in the size and texture of bread crumbs, which is crucial for culinary applications. Consistent quality improves the final product's texture and appearance, whether used in coatings, fillers, or toppings. |

Labor Cost Reduction | Automating the bread crumb production process reduces the need for manual labor, thereby lowering labor costs. This is especially beneficial for large-scale food processing operations. |

Versatility | Modern bread crumb makerscome with adjustable settings to produce various crumb sizes, from fine to coarse, catering to different culinary needs. This versatility allows for broader application in various recipes and dishes. |

Hygiene and Safety | Using a bread crumb makerminimizes human contact with the bread, reducing the risk of contamination. Many machines are designed with easy-to-clean parts and materials, ensuring compliance with hygiene standards. |

Cost-Effective | Over time, investing in a bread crumb maker can be more cost-effective than purchasing pre-made bread crumbs. Producing crumbs in-house allows businesses to utilize leftover bread efficiently, reducing waste and saving costs. |

Customization | Businesses can create custom bread crumb blends by adjusting the machine settings and using different types of bread. This ability to tailor bread crumbs to specific recipes enhances product offerings and customer satisfaction. |

Durability and Reliability | Industrial-grade bread crumb makers are built to withstand continuous use, offering durability and long-term reliability. These machines are designed to handle high production demands, ensuring consistent performance over time. |

Energy Efficiency | Modern bread crumb makers are designed to be energy-efficient, reducing operational costs and environmental impact. Energy-efficient machines consume less power while maintaining high productivity levels. |

Scalability | Bread crumb makers are available in various sizes and capacities, making them suitable for both small-scale and large-scale operations. This scalability allows businesses to choose machines that fit their current needs while having the option to upgrade as they grow. |

Key Innovations in Bread Crumb Maker Technology

The field of food processing equipment, particularly bread crumb makers, has seen significant advancements in recent years. These innovations are designed to enhance efficiency, improve product quality, and ensure greater versatility in culinary applications. Here are some of the key technological advancements in bread crumb maker technology:

Automated Control Systems

Modern bread crumb makers are equipped with sophisticated automated control systems. These systems allow precise adjustments to crumb size and texture, ensuring consistency across large batches. Automation reduces the need for manual intervention, increasing productivity and reducing the potential for human error.

Energy Efficiency

With growing concerns over energy consumption and environmental impact, manufacturers have developed more energy-efficient bread crumb makers. These machines are designed to minimize power usage while maintaining high output levels, making them more cost-effective and environmentally friendly.

Enhanced Safety Features

Safety is paramount in food processing. Advanced bread crumb makers now include enhanced safety features such as automatic shutoff, overload protection, and built-in sensors that monitor machine performance. These features help prevent accidents and ensure compliance with industrial safety standards.

Modular Design

The modular design of modern bread crumb makers allows for easier maintenance and customization. Users can add or remove components based on their specific needs, making the machines more versatile and adaptable to different production requirements. This design also facilitates easier cleaning and sanitation, which is crucial in maintaining food safety standards.

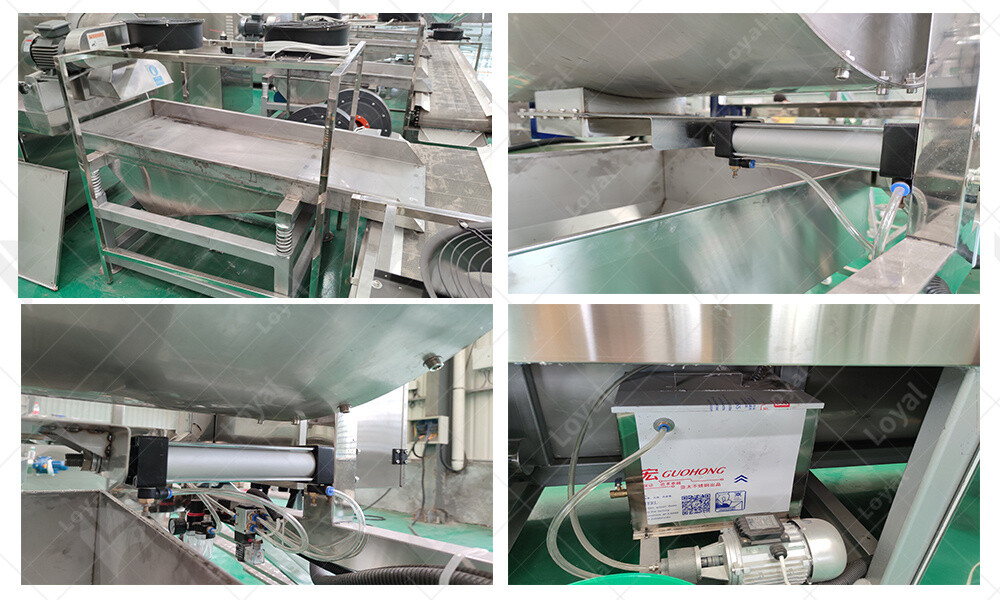

Improved Materials and Durability

Innovations in materials science have led to the use of more durable and hygienic materials in the construction of bread crumb makers. Stainless steel and food-grade plastics are commonly used, offering resistance to corrosion and wear. These materials ensure the longevity of the machines and help maintain hygiene standards.

Integration with Other Systems

Modern bread crumb makers can be integrated with other food processing systems, such as mixers, blenders, and packaging machines. This integration streamlines the production process, reducing manual handling and improving overall efficiency. It also allows for seamless operation in automated production lines.

Smart Technology and IoT

The incorporation of smart technology and the Internet of Things (IoT) in bread crumb makers has revolutionized the industry. These machines can now be monitored and controlled remotely using smartphones or computers. Real-time data analytics help optimize performance, predict maintenance needs, and minimize downtime, ensuring continuous and efficient production.

Customization Capabilities

Innovations have also focused on the customization capabilities of bread crumb makers. Advanced models offer multiple settings for producing different types of bread crumbs, from fine to coarse. This flexibility allows food manufacturers to create a variety of products tailored to specific recipes and customer preferences.

Buying Guide for Bread Crumb Makers

When investing in a bread crumb maker, it's essential to consider various factors to ensure that you choose the right machine for your specific needs. Below is a comprehensive buying guide that highlights key considerations when purchasing a bread crumb maker:

Aspect | Description |

Capacity | Consider the production capacity of the bread crumb maker. Determine whether you need a machine for small-scale or large-scale production. |

Automation Level | Decide on the level of automation required. Manual, semi-automatic, and fully automatic bread crumb makersare available, each offering different levels of control and efficiency. |

Crumb Size Adjustment | Look for a bread crumb makerwith adjustable settings for crumb size. This feature allows you to produce crumbs of varying textures to suit different culinary applications. |

Construction Material | Check the construction material of the bread crumb maker. Stainless steel construction is preferred for its durability, corrosion resistance, and ease of cleaning. |

Safety Features | Ensure that the bread crumb makeris equipped with essential safety features such as overload protection, emergency stop buttons, and safety guards to prevent accidents. |

Energy Efficiency | Opt for an energy-efficient bread crumb makerto minimize operational costs and environmental impact. Look for machines with energy-saving features such as automatic shut-off and low power consumption. |

Ease of Cleaning | Consider the ease of cleaning and maintenance. Choose a bread crumb makerwith removable parts and accessible components for effortless cleaning and sanitation. |

Brand Reputation | Research the reputation of the brand and manufacturer. Choose a reputable brand known for producing high-quality and reliable bread crumb makers. |

Customer Support | Check the availability of customer support and after-sales service. Opt for a manufacturer that offers comprehensive customer support, including technical assistance, spare parts availability, and warranty coverage. |

Price | Compare prices from different manufacturers and consider the overall value offered by the bread crumb maker. Avoid compromising quality for a lower price and prioritize long-term reliability and performance. |

Installation and Setup

When it comes to setting up your bread crumb maker, proper installation is key to ensuring optimal performance and efficiency. Here's a step-by-step guide to help you navigate through the installation and setup process:

1. Site Selection

Site selection is the first crucial step in installing your bread crumb maker. Choose a location that provides adequate space for the machine and allows easy access for maintenance and operation. Ensure the area is well-ventilated and free from obstructions to prevent overheating and ensure proper airflow.

2. Leveling the Machine

Before installing the bread crumb maker, ensure that the floor surface is level and stable. Use a spirit level to check for any unevenness and adjust the machine's leveling feet accordingly. Proper leveling is essential to prevent vibrations and ensure smooth operation during use.

3. Electrical Connection

Next, connect the machine to the power supply following the manufacturer's instructions and local electrical codes. Ensure that the power source meets the machine's voltage and current requirements to prevent electrical issues and potential damage. Use appropriate wiring and connectors to secure the electrical connection safely.

4. Plumbing Connection (if applicable)

If your bread crumb maker requires a water supply for operation or cleaning, ensure that the plumbing connection is properly installed. Follow the manufacturer's guidelines for connecting water lines and installing any necessary filters or regulators to maintain water quality and pressure.

5. Calibration and Testing

Once the machine is installed and connected, perform calibration and testing to ensure proper operation. Follow the manufacturer's instructions to calibrate the machine's settings, such as crumb size adjustment and speed control. Conduct thorough testing to verify that all functions are working correctly and troubleshoot any issues that may arise.

6. Safety Precautions

Before operating the bread crumb maker, review and implement safety precautions to prevent accidents and injuries. Train operators on proper machine usage, emergency procedures, and safety protocols. Provide personal protective equipment (PPE) as necessary and post safety signage in the area.

7. Regular Maintenance Schedule

Establish a regular maintenance schedule to keep your bread crumb maker in optimal condition. Schedule routine inspections, cleaning, and lubrication of moving parts to prevent wear and ensure longevity. Keep detailed maintenance records and address any issues promptly to avoid downtime and costly repairs.

Operating a Bread Crumb Maker

Operating a bread crumb maker requires precision, attention to detail, and a thorough understanding of the machine's functionality. Here's a comprehensive guide to help you master the operation of your bread crumb maker:

1. Pre-Operation Inspection

Before starting the bread crumb maker, conduct a pre-operation inspection to ensure that the machine is in proper working condition. Check for any signs of damage, loose parts, or debris that may affect performance. Verify that all safety features are functional and that the machine is clean and sanitized.

2. Power On the Machine

Once the pre-operation inspection is complete, power on the machine following the manufacturer's instructions. Ensure that the power source is properly connected and that all electrical components are functioning correctly. Monitor the machine for any unusual sounds or vibrations during startup.

3. Set Crumb Size and Texture

Adjust the crumb size and texture settings on the bread crumb maker according to your desired specifications. Use the machine's controls to customize the size and texture of the bread crumbs based on your culinary requirements. Fine-tune the settings to achieve the desired consistency and texture.

4. Load Bread into the Hopper

Carefully load bread into the hopper of the bread crumb maker. Ensure that the bread slices are evenly distributed and that the hopper is not overloaded, as this can affect the machine's performance. Use fresh, high-quality bread for best results and avoid using stale or moist bread, which can result in uneven crumbs.

5. Start the Crumbing Process

Once the bread is loaded, start the crumbing process by activating the machine's controls. Monitor the machine closely as it begins to process the bread, ensuring that the crumbs are being produced consistently and evenly. Adjust the settings as needed to achieve the desired crumb size and texture.

6. Monitor Production

Throughout the crumbing process, closely monitor the production of bread crumbs to ensure quality and consistency. Keep an eye on the machine's performance indicators, such as motor speed and crumb output, and make adjustments as necessary to maintain optimal operation. Regularly inspect the crumbs for uniformity and adjust settings accordingly.

7. Collect and Store Bread Crumbs

As the bread crumb maker produces crumbs, collect them in a suitable container or receptacle. Ensure that the container is clean and sanitized to prevent contamination of the crumbs. Once collected, store the bread crumbs in airtight containers or bags to maintain freshness and prevent moisture absorption.

8. Shutdown and Clean

After completing the crumbing process, shutdown the machine following the manufacturer's guidelines. Disconnect the power source and allow the machine to cool down before proceeding with cleaning and maintenance. Thoroughly clean all parts of the bread crumb maker to remove any residue and ensure hygiene.

9. Regular Maintenance

Establish a regular maintenance schedule for your bread crumb maker to keep it in optimal condition. Schedule routine inspections, lubrication of moving parts, and replacement of worn components to prevent downtime and ensure longevity. Keep detailed maintenance records and address any issues promptly to avoid disruptions in operation.

Future Developments in Bread Crumb Makers

As technology continues to advance, the future of bread crumb makers holds promising developments aimed at enhancing efficiency, productivity, and versatility. Here are some anticipated advancements in bread crumb maker technology:

Future bread crumb makers are expected to feature enhanced automation and artificial intelligence capabilities, allowing for more autonomous operation and adaptive performance. AI algorithms will optimize crumb size and texture based on real-time feedback, ensuring consistent quality and minimizing waste.

Anticipate bread crumb makers to incorporate integrated quality control systems that monitor and regulate various parameters throughout the crumbing process. These systems will detect and correct deviations in crumb size, moisture content, and other factors to maintain product quality and compliance with industry standards.

Future bread crumb makers will offer greater customization options, allowing users to tailor crumbs to specific preferences and applications. Advanced controls and settings will enable precise adjustment of crumb size, texture, and flavor, catering to diverse culinary requirements and consumer preferences.

In response to growing environmental concerns, bread crumb makers of the future will integrate sustainability features aimed at reducing energy consumption and minimizing waste. Energy-efficient designs, recycling capabilities, and eco-friendly materials will contribute to a more sustainable food processing industry.

Expect future bread crumb makers to incorporate remote monitoring and control capabilities, enabling operators to oversee machine performance and make adjustments from anywhere via mobile devices or computers. This remote access feature will enhance convenience, efficiency, and responsiveness in production facilities.

Advancements in bread crumb maker technology will include enhanced safety features to protect operators and ensure compliance with stringent safety regulations. Improved guarding, sensors, and emergency stop systems will enhance operator safety and minimize the risk of accidents in the workplace.

Future bread crumb makers will feature modular design, allowing for easy customization, expansion, and maintenance. Modular components will facilitate quick assembly, disassembly, and reconfiguration, enabling manufacturers to adapt to changing production needs and market demands efficiently.

The integration of data analytics and predictive maintenance capabilities will enable proactive maintenance scheduling and performance optimization in bread crumb makers. Machine learning algorithms will analyze operational data to predict potential issues and schedule maintenance tasks accordingly, reducing downtime and maximizing uptime.

Anticipate future bread crumb makers to prioritize improved hygiene and sanitation, with features such as self-cleaning systems, antimicrobial surfaces, and easy-access components for thorough cleaning. These advancements will ensure compliance with strict food safety standards and minimize the risk of contamination.

Future bread crumb makers will feature enhanced user interfaces with intuitive controls, interactive displays, and user-friendly menus. Streamlined interfaces will simplify operation, reduce training time for operators, and enhance overall user experience in food processing facilities.

References

The following are five authoritative foreign literature websites in the field of industrial bread crumb maker:

1.ScienceDirect

Website: [https://www.sciencedirect.com/]

2.IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

3.SpringerLink

Website: [https://link.springer.com/]

4.Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5.Taylor & Francis Online

Website: [https://www.tandfonline.com/]