The Ultimate Guide to Biscuit Maker Machine Prices in 2024

Understanding Biscuit Maker Machine Types

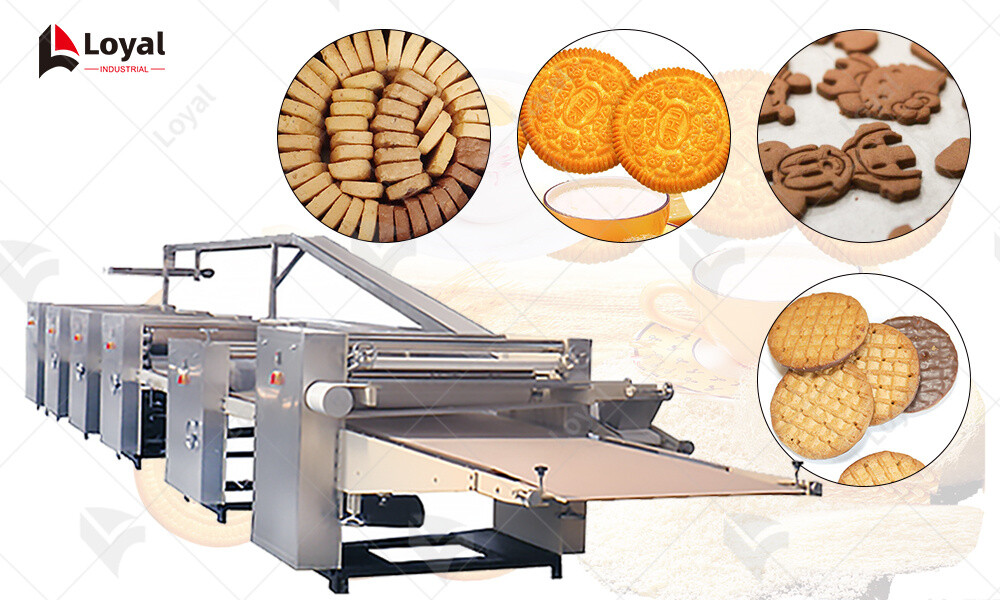

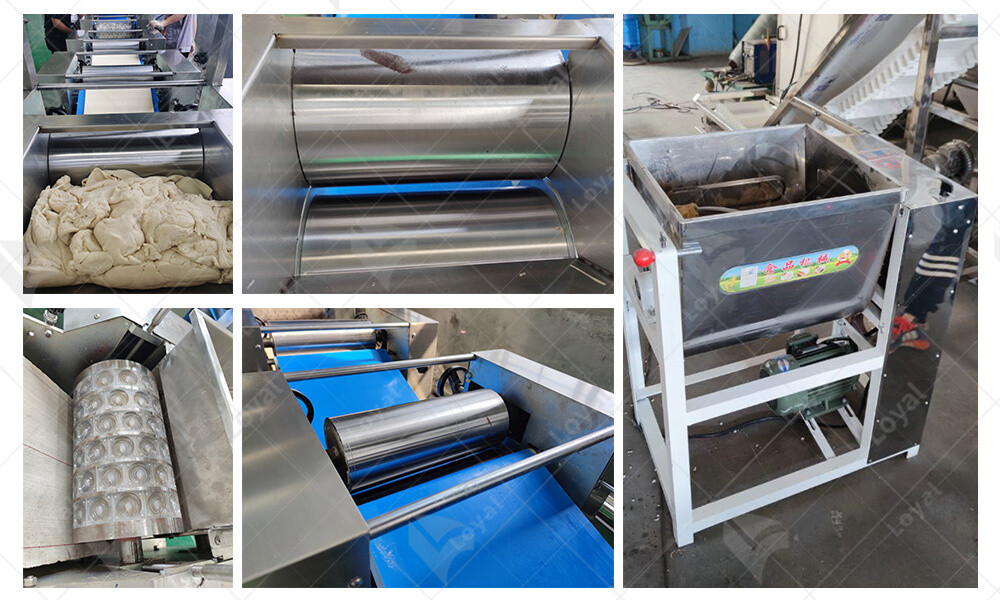

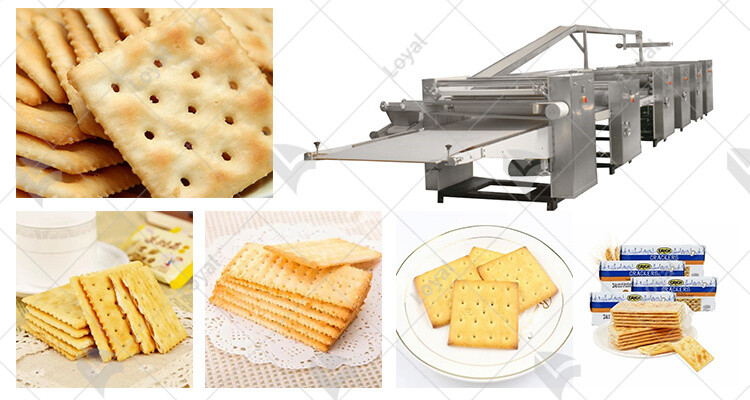

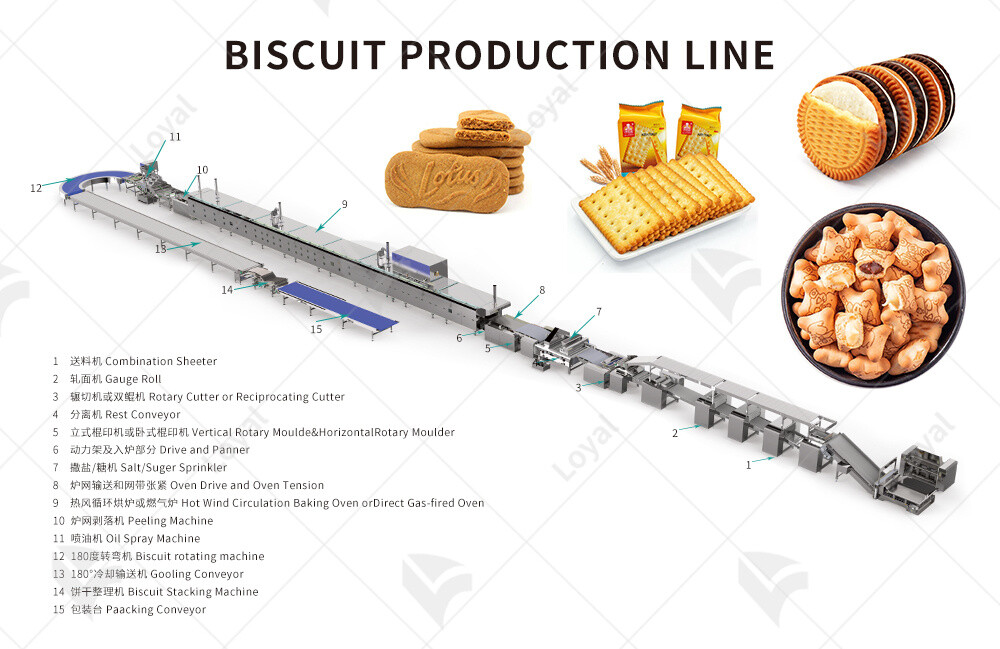

Rotary Moulder Machines: Rotary moulder machines are essential in the production of biscuits with intricate designs or patterns. They consist of a rotating drum with cavities that shape the dough into desired forms. These machines are ideal for manufacturing biscuits like cream-filled or sandwich biscuits, where precise shaping is necessary for the final product's aesthetics and functionality.

Wire Cut Machines: Wire cut machines are versatile equipment commonly used in the biscuit industry. They work by extruding dough through a nozzle, which is then cut into desired shapes using a series of wires. This type of machine is suitable for producing a wide range of biscuits, including plain, round, or shaped varieties. Wire cut machines offer flexibility in product design and are favored for their efficiency in high-volume production.

Depositor Machines: Depositor machines are ideal for producing biscuits with fillings or multiple layers. They work by depositing precise amounts of dough and filling onto a moving conveyor belt. These machines are capable of handling various types of dough and fillings, making them suitable for manufacturing biscuits with diverse flavors and textures. Depositor machines are commonly used in the production of cookies, filled biscuits, and snack bars.

Factors Influencing Biscuit Maker Machine Prices

When investing in a biscuit maker machine, several factors can influence the pricing. Understanding these factors is essential for businesses to make informed decisions and optimize their investments. Below is a detailed overview of the key factors influencing biscuit maker machine prices:

| Factor | Description |

| Capacity | The production capacity of the machine, measured in units per hour, significantly impacts its price. Machines with higher capacities command higher prices due to their ability to handle larger volumes of production. |

| Technology and Features | Advanced technology and additional features, such as touchscreen interfaces, automated cleaning systems, and recipe management software, contribute to higher machine prices. These features enhance operational efficiency, product quality, and ease of use, justifying the higher investment. |

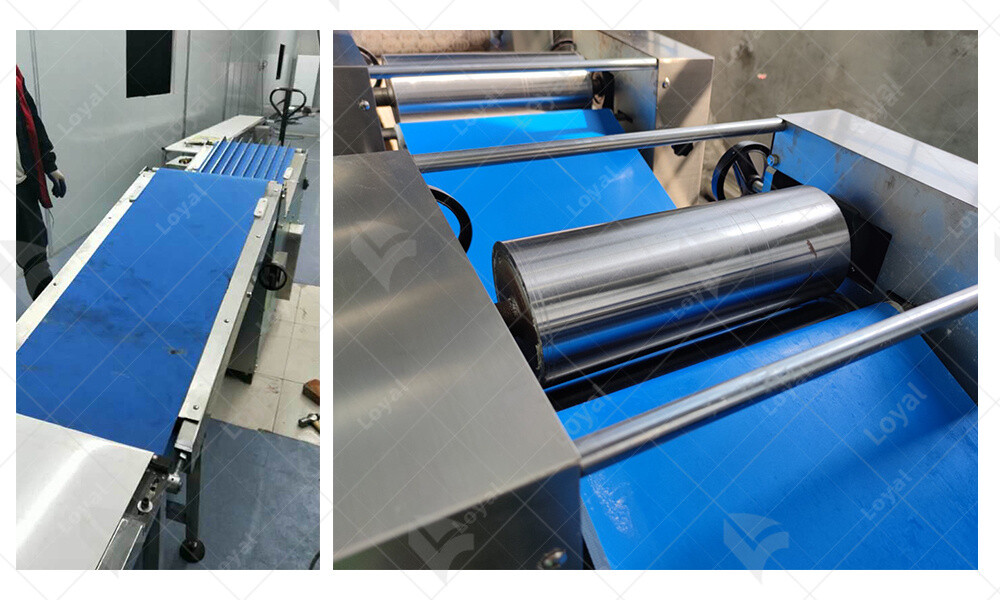

| Build Quality and Materials | The quality of materials used in construction, such as stainless steel for food-contact surfaces and robust components for durability, affects machine prices. Machines built with high-quality materials are more durable and reliable, reducing maintenance costs and downtime in the long run. |

| Brand Reputation and Support | Established brands with a reputation for reliability and excellent customer support often offer machines at premium prices. Investing in a reputable brand ensures access to reliable technical support, spare parts availability, and comprehensive warranties, which are essential for long-term operational success. |

| Customization Options | Machines that offer customization options to suit specific production requirements may have higher prices. Customization allows businesses to tailor the machine's features and capabilities to their unique production processes, optimizing efficiency and product quality. |

| Regulatory Compliance and Certifications | Machines that meet industry standards and regulatory requirements, such as food safety certifications and compliance with international standards, may have higher prices. Compliance with regulations ensures product safety and quality, reducing the risk of costly recalls and legal issues. |

Comparing Biscuit Maker Machine Brands

The biscuit maker machine market is populated by numerous brands, each offering unique advantages. Notable brands in 2024 include LOYAL Machines, BakeMaster, and ProBake Solutions. Each brand has its own strengths and pricing strategy, making it essential to compare them carefully.

LOYAL Machines: Known for their robust and durable biscuit maker machines, LOYAL Machines caters to large-scale industrial operations. Their machines are designed for high-volume production and offer advanced automation features. The biscuit maker machine price for LOYAL Machines typically ranges from $15,000 to $50,000, depending on the model and customization options.

BakeMaster: BakeMaster targets medium to large bakeries, offering a balance between performance and cost. Their machines are known for their reliability and ease of use. BakeMaster's biscuit maker machine price usually falls between $10,000 and $30,000, making them an attractive option for businesses looking to scale up production without a massive investment.

ProBake Solutions: This brand specializes in innovative technology and high efficiency. ProBake Solutions is favored by businesses that require precision and consistency in their biscuit production. The biscuit maker machine price for ProBake Solutions ranges from $20,000 to $40,000, reflecting their focus on quality and cutting-edge features.

When comparing brands, it's crucial to consider not just the initial biscuit maker machine price but also the long-term value and operational costs. Factors such as machine longevity, maintenance requirements, and energy efficiency play significant roles in the overall cost-effectiveness of the machine.

Evaluating Biscuit Maker Machine Features

In addition to brand comparison, evaluating the features of biscuit maker machines is essential for making an informed purchase. The key features to consider include automation level, production capacity, ease of maintenance, and customization options.

Automation Level: Modern biscuit maker machines offer various levels of automation, from semi-automatic to fully automatic systems. Fully automatic machines, while more expensive, significantly reduce the need for manual intervention and increase production efficiency. The biscuit maker machine price for fully automated models is higher, but the investment is often justified by the labor savings and increased output.

Production Capacity: The production capacity of a biscuit maker machine is a critical factor, especially for large-scale operations. Machines with higher production capacities can produce more biscuits per hour, meeting the demands of larger markets. However, these machines come with a higher biscuit maker machine price. It's important to match the machine's capacity with your production needs to avoid over or under-investing.

Ease of Maintenance: Maintenance is an ongoing cost that can impact the total cost of ownership. Machines that are easy to clean and maintain help minimize downtime and prolong the machine's lifespan. When evaluating biscuit maker machine prices, consider the availability of spare parts and the manufacturer's support services.

Customization Options: Different businesses have different production requirements, and customization options can provide the flexibility needed to meet specific demands. Machines that allow customization of biscuit shapes, sizes, and recipes can be advantageous. While these options may increase the initial biscuit maker machine price, they offer the ability to diversify product offerings and adapt to market trends.

Budgeting for a Biscuit Maker Machine Purchase

| Factor | Description | Price Range |

| Machine Size and Capacity | Smaller machines for small-scale production | $5,000 - $10,000 |

| Large-scale industrial machines | $50,000 - $100,000+ | |

| Technological Features | Advanced features (automated control, precision cutting, custom shaping) | Higher costs, variable based on features |

| Brand and Quality | Renowned brands with reliable and durable machines | Higher prices due to brand reputation |

| Customization and Add-Ons | Custom molds, additional cutting heads, specific modifications | Additional costs, several thousand dollars |

Exploring Cost-Effective Biscuit Maker Machine Options

For businesses seeking cost-effective biscuit maker machine options, several strategies can help optimize your investment without compromising on quality and efficiency. Here are some tips to explore affordable yet reliable machines:

Evaluate Second-Hand Machines: Purchasing second-hand biscuit maker machines can be a cost-effective alternative to buying new ones. Many suppliers offer refurbished machines that have been inspected and restored to good working condition. This option can provide substantial savings while still delivering reliable performance.

Leverage Bulk Discounts: If you’re planning to purchase multiple machines, inquire about bulk purchase discounts. Suppliers often provide reduced prices for bulk orders, making it an economical choice for expanding your production capacity.

Consider Regional Manufacturers: Sometimes, regional manufacturers offer competitive prices compared to international brands. These manufacturers may provide machines that meet your production needs at a lower cost due to reduced shipping expenses and local market conditions.

Negotiate Payment Terms: Some suppliers offer flexible payment terms that can ease the financial burden of purchasing a new biscuit maker machine. Negotiating installment plans or deferred payment options can help manage your budget more effectively.

Research Government Subsidies and Grants: Certain regions offer government subsidies or grants for businesses investing in industrial machinery. Research available programs that support the food manufacturing industry, as these can significantly offset the cost of acquiring new equipment.

By carefully considering these cost-effective strategies, businesses can find biscuit maker machines that align with their budget while maintaining high production standards. The key is to balance initial costs with long-term benefits, ensuring that the chosen machine delivers value over its operational lifespan.

Analyzing Long-Term Maintenance Costs

When investing in a biscuit maker machine, it's crucial to consider long-term maintenance costs. These expenses can significantly affect the overall biscuit maker machine price. Regular maintenance is necessary to ensure the machine operates efficiently and prolong its lifespan. This includes periodic inspections, part replacements, and lubrication, which can add up over time.

Furthermore, the complexity of the machine plays a role in maintenance costs. Advanced biscuit maker machines with more automated features may require specialized technicians for repairs, which can be costly. It's essential to factor in these potential expenses when evaluating the overall investment.

Another aspect to consider is the availability of spare parts. Machines from well-known manufacturers often have readily available parts, whereas lesser-known brands might pose challenges in sourcing replacements, leading to increased downtime and higher costs. Therefore, choosing a reputable brand can mitigate these issues and provide a clearer picture of the biscuit maker machine price over its lifespan.

Lastly, consider the warranty and service agreements offered by the manufacturer. A comprehensive warranty can cover significant maintenance costs for a certain period, reducing the financial burden. Understanding these long-term costs is vital for making an informed decision about the total biscuit maker machine price.

Negotiating Biscuit Maker Machine Prices

Negotiating the price of a biscuit maker machine can lead to substantial savings, making it an essential step in the purchasing process. Start by conducting thorough research on different models and their market prices. Having a clear understanding of the average biscuit maker machine price puts you in a stronger position to negotiate effectively.

During negotiations, emphasize the volume of purchase if you are buying multiple units. Manufacturers and suppliers are often willing to offer discounts for bulk purchases. Additionally, discuss any additional features or customizations you might need. Sometimes, negotiating these extras can lead to a better overall deal, rather than just focusing on the base price.

Another effective strategy is to compare offers from multiple suppliers. This competitive approach can encourage suppliers to lower their prices or offer better terms to secure your business. Don't hesitate to let suppliers know you are comparing prices; it can prompt them to present their most competitive biscuit maker machine price.

Lastly, consider the timing of your purchase. Manufacturers may offer discounts during certain times of the year, such as end-of-quarter sales or during trade shows. Being aware of these opportunities can help you secure a better deal on your biscuit maker machine price.

Considering Used vs. New Biscuit Maker Machines

When evaluating biscuit maker machine prices, it's essential to consider the pros and cons of used versus new machines. New biscuit maker machines come with the latest technology, warranties, and support from the manufacturer. These advantages can justify a higher initial biscuit maker machine price due to the reduced risk of breakdowns and the availability of after-sales service.

However, used biscuit maker machines can be a cost-effective alternative. The lower initial purchase price can make them attractive, especially for businesses with limited budgets. It's important to thoroughly inspect used machines for any signs of wear and tear that could lead to future maintenance issues. Additionally, checking the machine's history, such as previous usage and maintenance records, can provide insight into its reliability.

One of the main concerns with used machines is the lack of a warranty. This can lead to higher maintenance costs if the machine breaks down. It's advisable to work with reputable dealers who can provide some form of guarantee or return policy.

Ultimately, the decision between used and new should be based on a thorough cost-benefit analysis. While used machines may offer immediate savings on the biscuit maker machine price, new machines can provide long-term reliability and lower maintenance costs.

Future Trends in Biscuit Maker Machine Pricing

As we look ahead to 2024 and beyond, several trends are likely to influence biscuit maker machine prices. Technological advancements continue to drive the market, with automation and AI integration becoming more prevalent. These innovations can increase the initial biscuit maker machine price but offer significant long-term savings through enhanced efficiency and reduced labor costs.

Sustainability is another trend impacting pricing. Manufacturers are increasingly adopting eco-friendly materials and energy-efficient designs to meet regulatory standards and consumer demand for greener products. While this shift may initially raise the biscuit maker machine price, the long-term benefits include lower operational costs and a reduced environmental footprint.

Economic factors, such as inflation and supply chain disruptions, also play a role in future pricing. Fluctuating raw material costs and global trade dynamics can lead to price volatility. Staying informed about these factors can help businesses plan their investments more effectively.

Finally, the growing demand for customization in the food industry is influencing biscuit maker machine prices. As consumers seek unique and personalized products, manufacturers are offering machines with customizable features. This trend can increase the initial cost but provides businesses with the flexibility to meet diverse market demands.

In conclusion, staying abreast of these trends and understanding their impact on biscuit maker machine prices will help businesses make informed purchasing decisions in the evolving landscape of 2024.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com