Sustainable Innovation: Fully Automatic Chili Powder Sterilization Machine Redefining Efficiency

Introduction

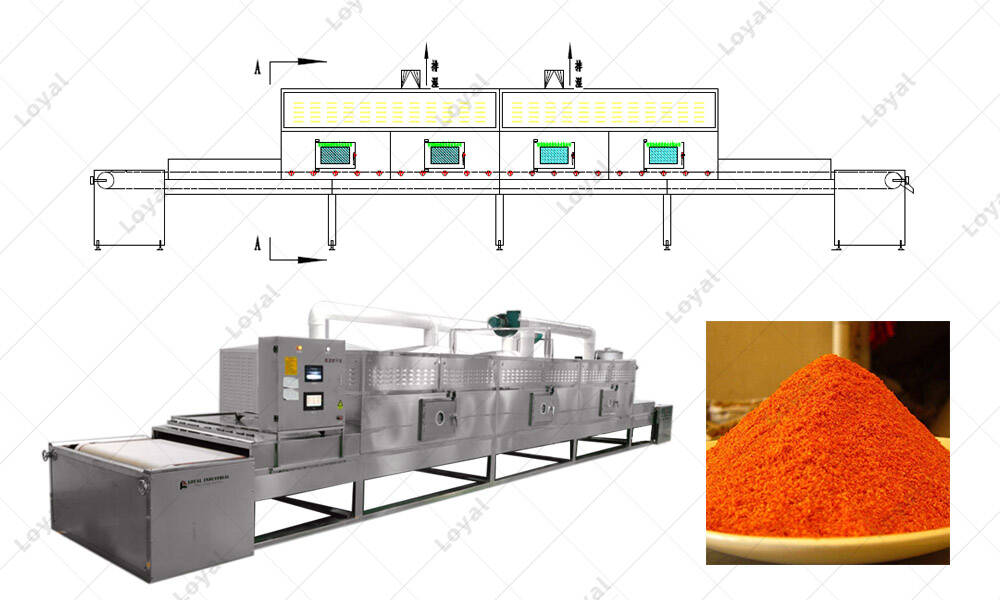

Our company leverages cutting-edge technologies from Cellencor and IMS to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Cellencor and IMS, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Evolution of Chili Powder Sterilization Technologies

As we delve into the evolution of chili powder sterilization, it becomes evident that historical methods have undergone transformations due to the evolving needs and standards in the food processing industry. This section will trace the journey of sterilization technologies, highlighting the demand for advanced solutions that led to the development of the groundbreaking Chili Powder Sterilization Machine.

Sustainable Technological Advancements

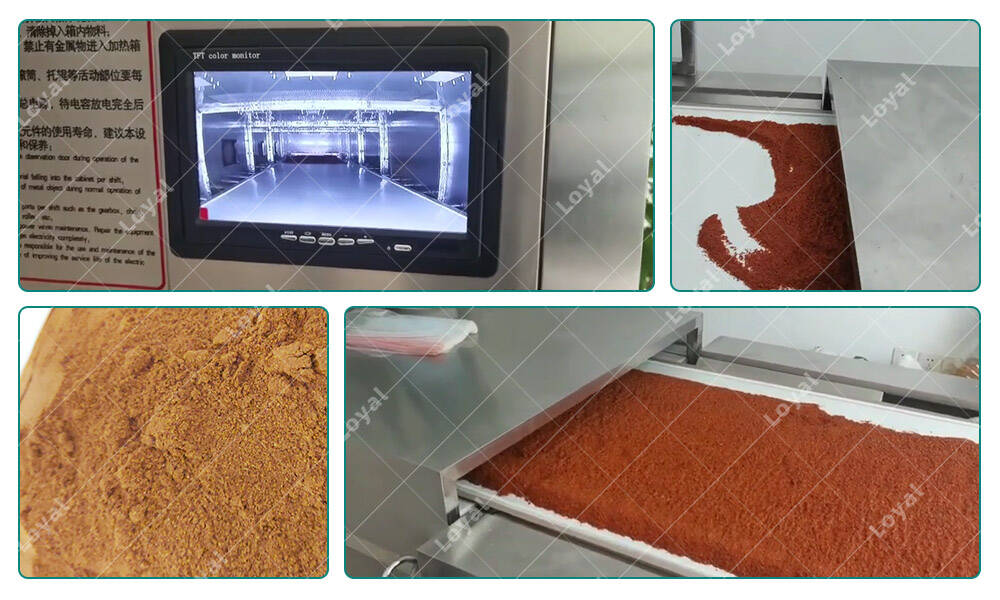

An in-depth examination of the operational features of the Chili Powder Sterilization Machine will showcase its sustainable technological advancements. We will explore how this machine incorporates cutting-edge sustainable practices to enhance efficiency in chili powder sterilization. The discussion will emphasize the benefits and advantages it offers over traditional methods, with a keen focus on minimizing environmental impact.

Precision and Quality in Sustainable Sterilization

This section will provide a comprehensive overview of how the fully automatic system ensures precision in sterilization processes, enhancing the overall quality of chili powder products. It will delve into the sustainable practices integrated into the technology, underscoring the machine's role in maintaining product integrity throughout the processing journey.

Integration into Sustainable Chili Powder Processing

Examining the seamless integration of the Chili Powder Sterilization Machine into chili powder processing, we'll explore real-world applications and case studies. These examples will illustrate how the machine contributes to increased efficiency and productivity while concurrently reducing the environmental footprint. The adaptability of the machine to various stages of chili powder manufacturing will also be a focal point.

Economic and Environmental Sustainability

A thorough analysis of the economic benefits and cost efficiency offered by the fully automatic system will be presented, with a strong emphasis on sustainability. Environmental sustainability aspects, such as reduced energy consumption and waste, will be highlighted. The section aims to showcase how the technology contributes to overall operational excellence and resource optimization in a sustainable manner.

Technological Innovations and Future Sustainable Trends

Exploring ongoing technological innovations in sustainable chili powder sterilization, this section will discuss how the Fully Automatic Chili Powder Sterilization Machine is evolving to meet emerging industry demands. Anticipation of future trends and advancements in sustainable technology will provide valuable insights into the trajectory of the industry.

Regulatory Compliance and Safety with a Sustainability Focus

Ensuring regulatory compliance and safety standards is crucial for the Chili Powder Sterilization Machine. This section will explore the certifications and safety measures integrated into the sustainable technology, showcasing the industry's commitment to quality, safety, and sustainable practices.

Sustainable Case Studies: Success Stories with Fully Automatic Chili Powder Sterilization

Real-world examples will be presented to demonstrate how the Chili Powder Sterilization Machine has contributed to sustainable success in chili powder manufacturing. Case studies will highlight how manufacturers have achieved their sustainability goals through the adoption of this advanced technology.

Conclusion

In conclusion, this section will summarize the key points discussed in the article. It will emphasize how the Fully Automatic Chili Powder Sterilization Machine, through sustainable innovation, is redefining efficiency in chili powder processing. The call to action will encourage manufacturers to embrace sustainable technology for elevated productivity, efficiency, and ecological responsibility in the food processing industry.

FAQs: Common Questions about Chili Powder Sterilization Machine

1. What is a Chili Powder Sterilization Machine, and how does it work?

Answer: The Chili Powder Sterilization Machine is an advanced piece of equipment designed to ensure the safety and quality of chili powder products. It employs cutting-edge technology to sterilize chili powder efficiently. The process typically involves heat treatment to eliminate contaminants and pathogens.

2. What sets the Chili Powder Sterilization Machine apart from traditional methods?

Answer: Unlike traditional methods, the machine integrates sustainable technologies, ensuring precision, quality, and reduced environmental impact. Its automation capabilities and adherence to stringent safety standards distinguish it, providing a significant upgrade over conventional approaches.

3. How does the machine maintain product integrity and quality?

Answer: The machine's precision in sterilization and sustainable practices contribute to maintaining the integrity and quality of chili powder products. It carefully controls variables to prevent degradation, ensuring the final product meets the highest quality standards.

4. Can the machine be integrated into existing chili powder processing lines?

Answer: Yes, the Chili Powder Sterilization Machine is designed for seamless integration into existing processing lines. Its adaptability allows manufacturers to incorporate this advanced technology into various stages of chili powder manufacturing without significant disruptions.

5. What are the economic benefits of adopting the Fully Automatic system?

Answer: Adopting the Fully Automatic system results in economic benefits such as increased efficiency, reduced labor costs, and optimized resource utilization. The machine's automation capabilities lead to higher productivity and cost savings in the long run.

6. Can you share success stories or case studies highlighting the machine's impact?

Answer: Certainly. Success stories and case studies showcase real-world examples where manufacturers achieved sustainable success through the adoption of the Chili Powder Sterilization Machine. These examples demonstrate the positive impact on efficiency, productivity, and sustainability.

7. How can manufacturers embrace sustainable technology in chili powder processing?

Answer: Manufacturers can embrace sustainable technology by investing in innovative solutions like the Chili Powder Sterilization Machine. This involves a commitment to environmentally friendly practices, efficient resource utilization, and a focus on producing high-quality, safe products.

This FAQ section aims to address common inquiries about the Chili Powder Sterilization Machine, providing valuable insights for those considering the adoption of this advanced and sustainable technology in their food processing operations.