Rubber Drying Microwave Oven

Description Of Rubber Drying Oven

The rubber drying oven is an oven specially used for drying and curing rubber products. The oven contains a chamber for heating and circulating air, which helps dry the rubber and cure it to the desired consistency. Rubber drying ovens usually have a temperature control system that can precisely adjust the temperature inside the oven. This is important because different types of rubber require different curing temperatures to achieve their desired properties. Rubber drying ovens also typically include a ventilation system to help remove moisture from the oven. This helps prevent the rubber from becoming too wet during the drying process, which can cause defects and other quality issues. Overall, a rubber drying oven is essential equipment for rubber product manufacturers, as it helps ensure that the rubber is properly dried and vulcanized, resulting in a high-quality finished product.

How To Dry The Rubber

1.Preheat the oven to the recommended temperature for the particular rubber type you are processing. Temperature and time will vary depending on the type and thickness of rubber.

2.Place rubber products on a clean, dry surface, such as a metal tray, making sure there is enough space between products for hot air to circulate.

3.After the oven is preheated, carefully place the tray with the rubber in the oven.

4.Close the oven door and set the timer for the recommended drying time based on the type and thickness of rubber.

5.Regularly monitor the drying process to ensure consistent temperature and humidity levels.

6.After the drying process is complete, turn off the oven and carefully remove the rubber product from the oven using gloves or protective tools.

7.Allow rubber to cool and settle at room temperature before handling. Remember to follow the manufacturer's instructions for your specific oven and the type of rubber you are using for best results.

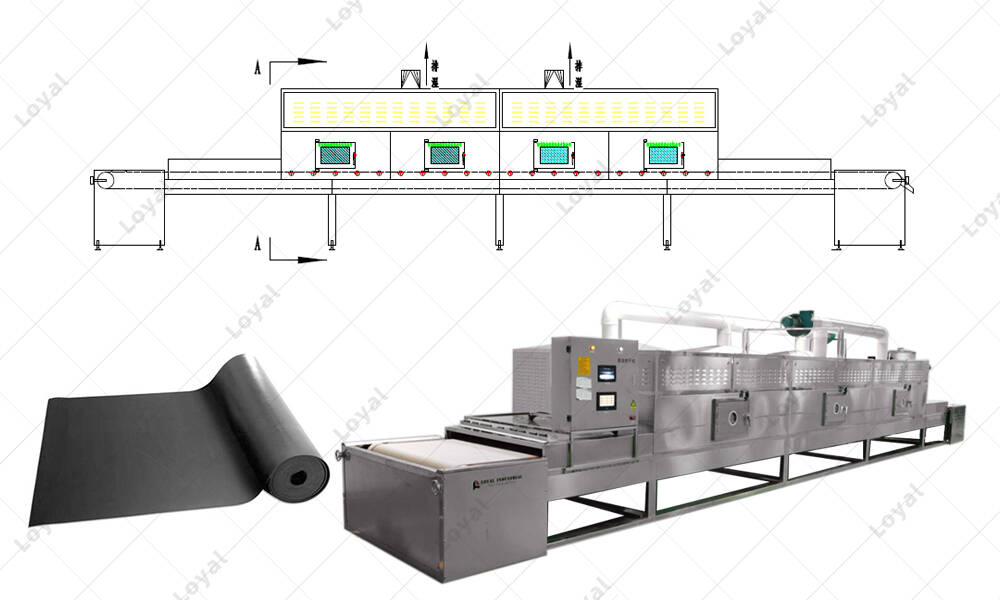

Working Principle Of Industrial Microwave Rubber Drying Oven

The working principle of industrial microwave rubber drying oven is to use microwave energy to generate heat to dry rubber. Microwaves are a form of electromagnetic radiation that are commonly used in a variety of applications, including cooking, communication and heating. In an industrial microwave rubber drying oven, rubber is exposed to a high-intensity microwave field generated by a magnetron. The microwaves penetrate the rubber and vibrate the water molecules inside the rubber, generating heat that helps remove the water. The rubber products are placed on the conveyor belt, and the water molecules are heated to evaporate the water through the microwave field. Temperature is controlled by adjusting microwave power and conveyor speed to ensure efficient drying without rubber damage or overdrying. Microwave rubber drying ovens are faster and more energy efficient than traditional drying methods, resulting in shorter drying times and lower energy costs. In addition, the process does not require the use of chemicals or solvents, making it environmentally friendly and safe for workers.

Microwave Rubber Dryer's Advantage

The working principle of industrial microwave rubber drying oven is to use microwave energy to generate heat to dry rubber. Microwaves are a form of electromagnetic radiation that are commonly used in a variety of applications, including cooking, communication and heating.

In an industrial microwave rubber drying oven, rubber is exposed to a high-intensity microwave field generated by a magnetron. The microwaves penetrate the rubber and vibrate the water molecules inside the rubber, generating heat that helps remove the water.

The rubber products are placed on the conveyor belt, and the water molecules are heated to evaporate the water through the microwave field. Temperature is controlled by adjusting microwave power and conveyor speed to ensure efficient drying without rubber damage or overdrying.

Microwave rubber drying ovens are faster and more energy efficient than traditional drying methods, resulting in shorter drying times and lower energy costs. In addition, the process does not require the use of chemicals or solvents, making it environmentally friendly and safe for workers.

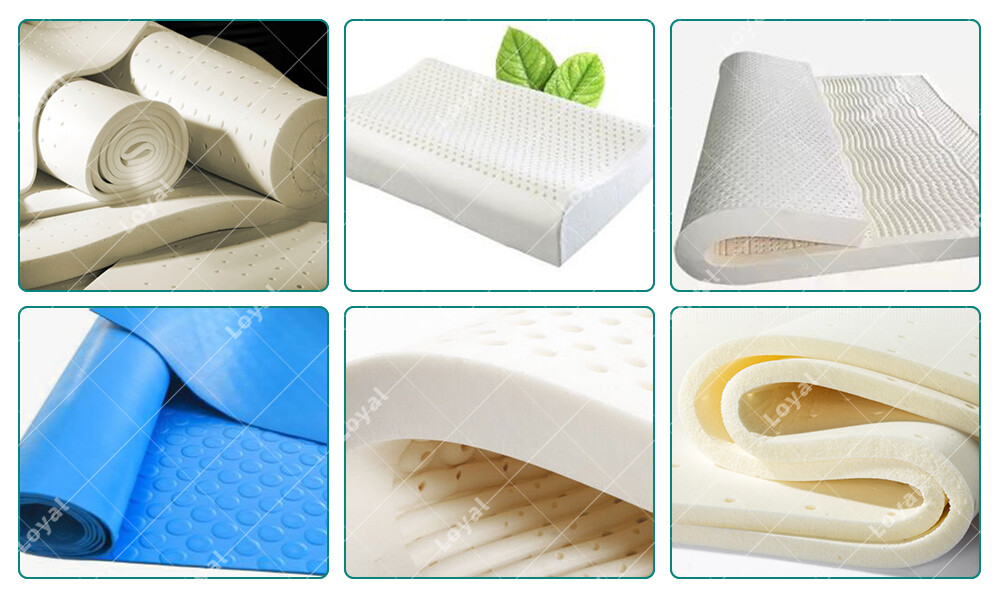

Rubber Product Display

Rubber products are made from natural rubber or synthetic rubber materials and are widely used in various industries such as automotive, construction, healthcare, consumer goods, etc. Some common rubber products include tires, conveyor belts, seals, gaskets, hoses and gloves.

Rubber products are durable, flexible, and resistant to abrasion, chemicals, and heat. They are also easy to shape, which makes them popular for creating intricate shapes and designs. In addition, rubber products can be customized to have various properties such as different hardness, elasticity and resilience.

Rubber products are manufactured through various processes such as extrusion molding, compression molding and injection molding. Raw materials are mixed with chemicals, fillers and pigments to form a compound, which is then processed into the desired shape.

Rubber products undergo quality control measures to ensure that they meet the prescribed specifications and standards. Quality control procedures include visual inspection, hardness testing and tensile strength testing.

Overall, rubber products play an important role in many applications, providing reliability, strength and durability to various industrial and consumer products.