Rice production line is widely used

Artificial rice has gradually begun to replace natural rice, becoming the most popular new staple food for consumers. The artificial rice produced by the Rice production line is rich in nutrients and has the same taste as the natural rice. It is not easy to deteriorate under the condition of long-term storage, which has gained the recognition of the majority of consumers.

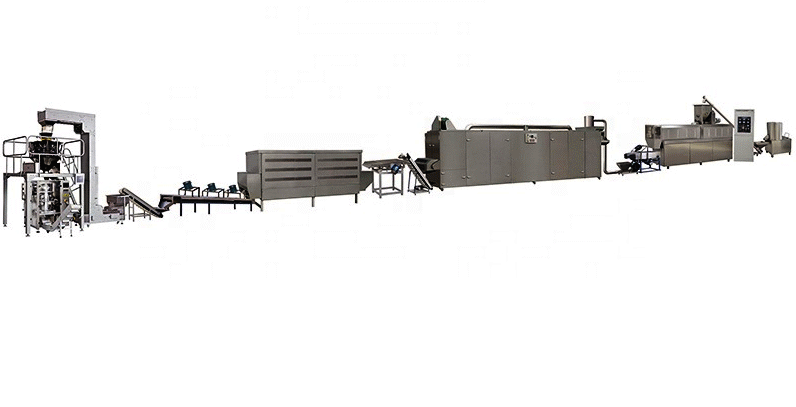

Rice production line is widely used to produce many types of rice, such as long, oval, black, purple, white, and yellow rice, etc. The rice produced is of very high quality, rich in taste and nutrition. The production line is still under continuous research and development. It will provide consumers with more types of artificial rice in the near future.

The reason why artificial rice equipment can process and produce such a rich variety of artificial rice is because of its very advanced production technology. The engineers develop the production line after combining the most advanced production technology globally, researching some practical problems encountered by many manufacturers in production, and making corresponding adjustments.

The processing method is complex, and each production step is very strict to ensure that the artificial rice produced is of high quality.

The production process of rice production line:

1. Mixing the raw materials in a blender, adding various nutritional elements, and mixing them well.

2. In the extruder, the raw materials are extruded and puffed to form rice granules.

3. High-speed vibration of the vibrating sieve separates the rice particles and prevents them from sticking together.

4. The drying process is carried out in the dryer.

5. The cooling conveyor line performs temperature reduction treatment, and the artificial rice after cooling is not easy to return to moisture, and the quality is higher.

6. Packaging.

The production line applies the world's leading extrusion technology in the production of artificial rice, which makes the artificial rice produced very satisfactory in terms of taste and nutritional content, so it is recognized by many manufacturers and has become the leading food machinery in the industry.

Rice production line is made of food-grade stainless steel and components of internationally famous brands, which has very stable quality and is not easy to damage during use and easy to clean. The line is reasonably designed, with a building block system structure, small footprint, and high degree of automation, which can help manufacturers further improve production efficiency and gain a broader market.

In order to enable more manufacturers to reduce cost pressure, the engineers of the Rice production line have effectively controlled the production cost after repeated research and development trials. It can also guarantee quality to the majority of manufacturers. The low investment cost for manufacturers means that they can be more competitive. The production line can bring an ideal market scale to most manufacturers and is the best choice for manufacturers to reduce production costs and improve brand awareness.