Professional Tea Drying Microwave Machine With Custom-Design Service

Introduction of Tea Drying Microwave Machine:

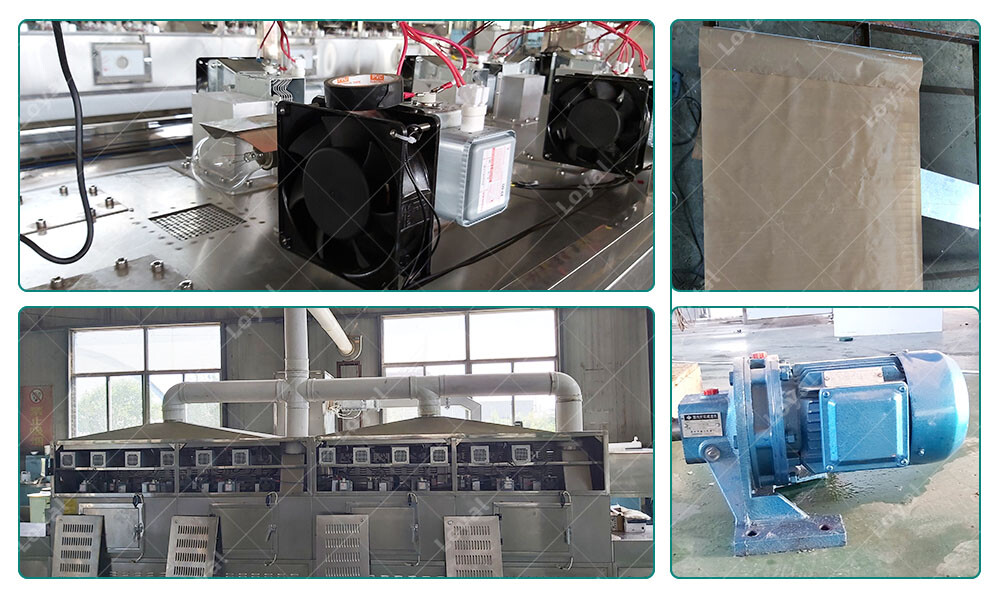

Tea Drying Microwave Machine can kill or dry tea in a few minutes, microwave drying is a direct interaction between microwave sources and food and its water molecules and other microorganisms, thermal and non-thermal effects work together to achieve rapid drying, processing time of the material is greatly reduced, the drying time of various materials is generally 5-10 minutes (in the case of mass production). Tea microwave dryer in the drying at the same time can also be effective sterilization of materials, which is a unique advantage of similar equipment does not have, the sterilization effect can reach the national standards. Tea microwave dryer is a national environmental protection equipment, the work of the equipment will not produce any harmful gases, equipment at both ends of the inhibitor device, the industry's mature technology will not cause any harm to humans, please rest assured that the purchase.

Feature Of Microwave Tea Drying Machine:

1.High efficiency: Microwave tea drying machines use microwave radiation to dry tea leaves, which is more efficient than conventional drying methods. The machines can reduce drying time by up to 50% while maintaining the quality of the tea leaves.

2. Precise temperature control: The machines have a temperature control system that enables users to set the required temperature for drying tea leaves. The system ensures that tea leaves are dried at the right temperature, preventing over or under-drying, which can affect the quality of the tea.

3. Uniform drying: The microwave radiation is evenly distributed across the tea leaves, providing uniform drying. The machines have a conveyor belt that moves the tea leaves through the chamber to ensure that all the tea leaves are exposed to the microwave radiation.

4. Retention of tea flavor and aroma: Microwave tea drying machines dry tea leaves quickly, which reduces the chance of the tea losing its flavor and aroma. The machines also prevent oxidation of tea leaves, which can result in a loss of flavor.

5. Easy operation: Microwave tea drying machines are easy to operate, and users can adjust the drying time and temperature according to the type of tea being processed. The machines require minimal maintenance, making them cost-efficient to operate in the long run.

Overall, microwave tea drying machines are an essential part of the tea processing industry as they provide a fast, efficient, and cost-effective way of drying tea leaves while maintaining their quality and flavor.

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Energy Efficient: The equipment uses less energy compared to traditional drying and sterilization methods, reducing energy costs and contributing to a more sustainable food manufacturing process.

2. Improved Product Quality: Microwave drying preserves the natural flavors, colors, and nutritional benefits of the food, resulting in a higher quality end product.

3. Uniform Drying and Sterilization: Microwave technology allows for even and consistent drying and sterilization, ensuring that all parts of the food are treated equally.

4. Reduced Microbial Load: Microwave sterilization can effectively eliminate harmful bacteria and pathogens from the surface of the food, ensuring that it is safe for consumption.

5. Increased Shelf Life: The reduction in moisture and microbial load can result in an extended shelf life of the food, reducing waste and enhancing food safety.

6. Versatility: Microwave drying and sterilization equipment can be used for a wide range of food products, including fruits, vegetables, meats, and grains, making it a more versatile tool in the food processing industry.

Overall, the benefits of microwave drying and sterilization equipment make it a valuable and cost-effective investment for food manufacturing companies looking to improve efficiency, quality, and safety.