Powder Drying Microwave Oven

Description Of Powder Drying Oven

A powder drying oven is a device that dries or dehydrates powder by heating with hot air. The oven consists of a temperature-controlled chamber that heats and circulates hot air throughout the interior. Put the powder into the oven, and the hot air circulates around the powder to remove moisture and dry it evenly. The drying process in powder drying cabinets is a critical step in many industries. Ovens can be used to dry various types of powders including chemicals, pharmaceuticals, food and more. Drying temperatures and times may vary depending on powder type, desired moisture content and desired final product quality. Powder drying cabinets are usually constructed of stainless steel or other corrosion-resistant materials to ensure hygiene and prevent contamination. It may also have advanced control systems, such as digital heat controllers and timers, to ensure accuracy and consistency in the drying process.

How To Dry The Powder

1.Prepare the oven: Make sure the oven is clean, dry and in good working order. Set the temperature to the desired level according to the powder to be dried.

2.Prepare the powder: Remove any moisture present in the powder. If necessary, preheat powder briefly to remove surface moisture.

3.Load into the oven: Place the powder on a drying tray or rack inside the oven. Make sure to leave enough space between each tray for proper air circulation.

4.Set the timer: Set the time required for the powder to dry. Drying times may vary depending on powder type, moisture content and oven temperature.

5.Monitor drying process: Regularly inspect powder to ensure uniform drying. If necessary, move the tray around to ensure that all areas of the powder dry at the same rate.

6.Removing the powder: After the drying process is complete, turn off the oven and let it cool down. Remove dry powder from tray or shelf.

7.Store powder: Place dry powder in an airtight container or package to prevent moisture from being reabsorbed.

Proper drying is critical to the quality and consistency of the final product. Therefore, the recommended drying conditions for the powder being dried must be followed.

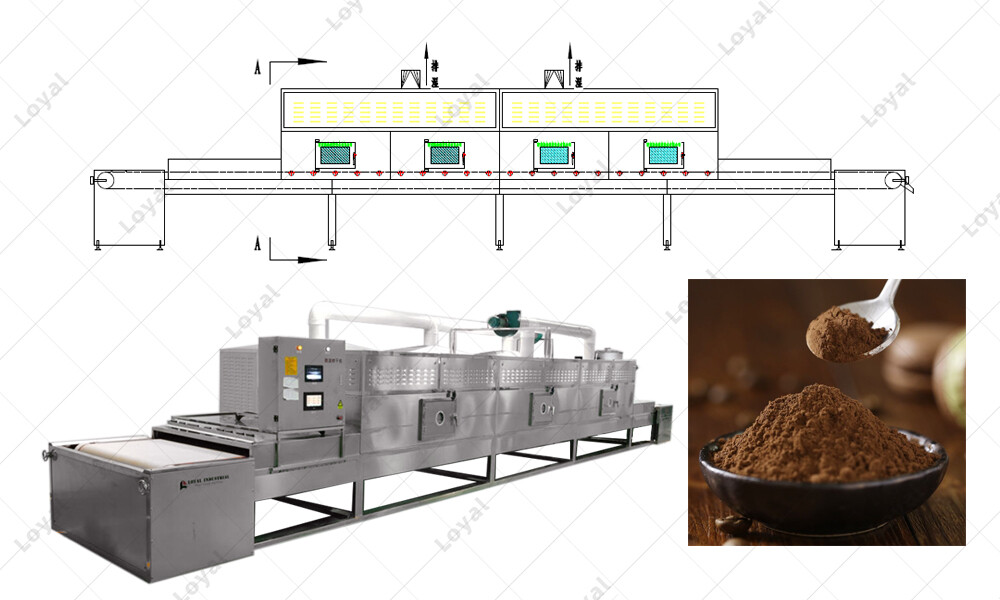

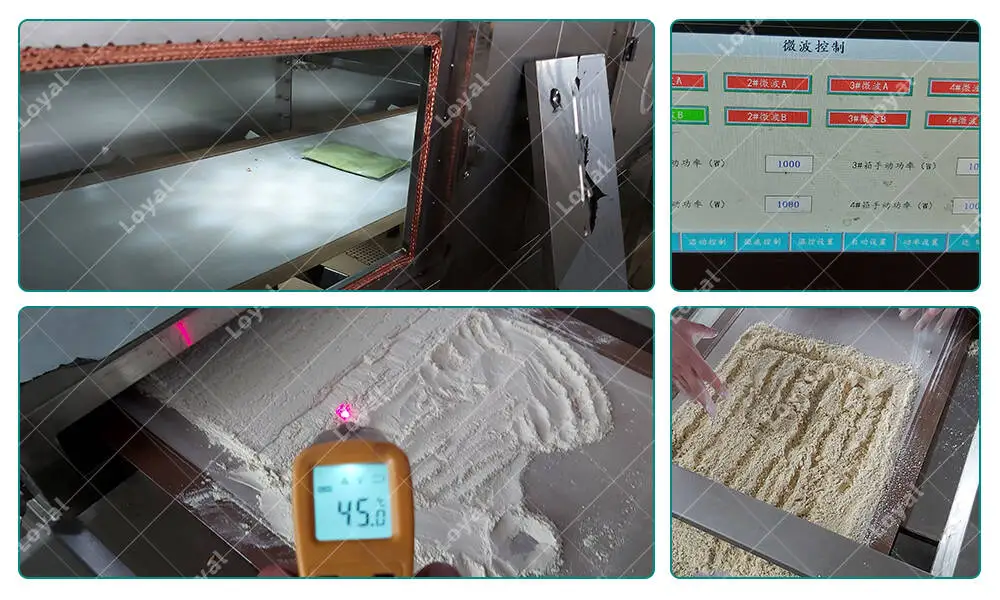

Working Principle Of Industrial Microwave Powder Oven

The working principle of industrial microwave powder oven is to use microwave energy to dry and heat powder. The oven consists of a microwave generator or magnetron that produces high-frequency, short-wavelength microwaves. These microwaves are then directed into the oven chamber using a waveguide. Inside the oven chamber, the powder is placed on a rotating carousel or conveyed through the oven using a conveyor belt. Microwaves penetrate the powder, causing water molecules in the powder to oscillate rapidly, generating heat. This heat then evaporates the moisture in the powder, resulting in a dry product. Oven temperature and drying time depend on the type and amount of powder to be dried. Microwave energy penetrates deeper into the powder compared to conventional drying methods, resulting in more uniform drying and shorter drying times. To ensure safety, the oven is designed to prevent microwave leakage. The oven's interlock system and shielding are set up to protect the operator from microwave radiation.

Microwave Powder Dryer's Advantage:

Faster Drying Time | The use of microwave energy generates high heat within the powder, resulting in faster drying times when compared to traditional drying methods. This reduces the total processing time and increases productivity. |

Better Product Quality | The use of microwave energy ensures uniform drying, which improves the product's quality. The process avoids over-drying, reducing the risk of the powder becoming burnt, discolored or losing its nutritional value. |

Energy Efficiency | The use of microwave energy saves energy and reduces drying costs, as the heating energy is generated directly in the powder. |

Increased Hygiene | With a shorter drying time, the risks for microbial growth are minimized, resulting in increased product hygiene. |

Flexibility | Microwave powder dryers are suitable for a wide range of powders, including heat-sensitive products, and can be used for continuous or batch drying. |

Environmental Considerations | Microwave drying is a "green" alternative to traditional drying methods due to its reduced energy consumption, less waste generation, and reduced carbon footprint. |

Powder Product Display

Powder products are a common form of consumer product and are in finely divided solid form. They have a wide range of applications, including foods such as spices, baking powder, protein supplements and mixed drinks. Other applications are found in the pharmaceutical industry for drug formulation and medical devices. They are also found in personal care products such as cosmetics and body care products. Powder products can be produced by various methods such as spray drying, freeze drying and agglomeration, depending on the nature of the product and the intended use. They are also packaged in different formats like sachets, bottles and cans to meet the needs of customers. Powder products have several advantages over their liquid or solid equivalents. Some of these advantages include ease of handling, longer shelf life and reduced shipping costs. Additionally, powders are often easier to store and consume in small quantities, allowing greater flexibility in food preparation or product use. Overall, powder products provide a convenient and effective form of product delivery that can be used in a variety of applications.