pet food production machines Manufacturers: How Comprehensive Guide To Selecting The Ideal Manufacturer

The Global Pet Consumption Market - Explosive Growth from 'Emotional Necessity' to a Trillion-Dollar Blue Ocean

The “pet economy” is sweeping the world at an astonishing speed! According to the latest industry data, the size of the global pet consumption market will reach US$296.8 billion in 2024, and will continue to expand at a compound annual growth rate of 5% until 2031, forming a trillion-dollar industry chain spanning food, supplies, medical care, and services 3 9 . Behind this “cute pet revolution” is a profound reconstruction of the relationship between people and pets - driven by the single economy, aging society and post epidemic emotional needs, pets have risen from “functional companion” to “functional companion”. “jumped up to” core family members ”to promote consumption from basic survival to quality, intelligence, emotional upgrade.

Regional differentiation and growth poles: North America leading, Southeast Asia rising. North America is still the largest market in the world, contributing over 40% of the market, with online pet sales in the US alone exceeding $156.7 billion in 2024, and its 70% penetration rate of pet ownership in households and mature “pet humanization” concepts have given rise to the twin giants of dog ($106.1 billion) and cat ($36.35 billion) products.9 And Southeast Asia is becoming a new growth pole with a 52% year-on-year growth rate: Indonesia's pet market is expected to reach $5.88 billion in 2033 (annual growth rate). Southeast Asia is becoming a new growth pole with a 52% year-on-year growth rate: Indonesia's pet market is expected to reach US$5.88 billion in 2033 (a 9.5% annual increase), Thailand's sales surged by 52.1% in the first half of 2024, and the demand for cat food has even surpassed that for dogs, reflecting the differences in regional consumer preferences.

However, in the face of this blue ocean, many entrepreneurs are deterred - traditional pet food production often requires millions of investment in equipment, complex production processes and large storage space, high threshold will be small and micro-entrepreneurs turned away. But today, designed for small entrepreneurs small pet feed production machine, is subverting the rules of the industry! It does not require a large factory building or professional engineers. Whether you want to build a brand of handmade customized food or supply exclusive products to pet stores, this machine can make “asset-light entrepreneurship” from concept to reality.

Why choose small pet feed production machine?

In the market wave where the pet economy has surpassed 400 billion yuan, small pet food production machines are becoming a game-changer for entrepreneurs and small to medium-sized enterprises. These compact devices are easy to install in various work environments and simple to operate, making them suitable for teams lacking professional technicians. Unlike large equipment that requires millions of investment, small machines offer lower entry barriers, more flexible production models, and faster return on investment, creating an efficient path for industry participants. They typically employ advanced automation technology to ensure the quality and consistency of the feed, while also allowing quick adjustments to production formulas based on market demand to meet the nutritional needs of different pets. Additionally, small machines have lower maintenance costs and lower failure rates, further reducing operational risks, enabling small and medium-sized enterprises to secure a foothold in the highly competitive market.

Low-cost investment: Starting a business with light assets

A large pet food production line integrates automated control systems and high-precision mixing devices, among other complex modules. The procurement cost for a single unit typically ranges from 800,000 to 1.5 million yuan. Adding the costs of factory renovations and power upgrades, the initial total investment often exceeds 2 million yuan. In contrast, small-scale production equipment uses modular design. For example, a basic configuration includes a small extruder (28,000 yuan), a mixer (12,000 yuan), and a semi-automatic packaging machine (8,000 yuan). The total procurement cost for this set can be controlled between 50,000 and 80,000 yuan, which is about one twenty-fifth of the cost of large-scale equipment. This lightweight investment model allows entrepreneurs to allocate more funds to product development and market promotion, significantly reducing startup risks.

Flexible production: accurately responding to market demand

Small equipment supports flexible production for batches of 100-500kg, capable of switching between dry and wet food production lines within 48 hours. This production model not only reduces inventory backlog risks but also accurately captures pet owners' consumption trends towards natural ingredients and functional formulas.

Quick returns: High turnover achieves profit goals

Take a small pet food factory in China as an example, investing $30,000 in production equipment, with a monthly production capacity of 110 tons. The payback period is only 11 months. In the trend of personalized and fragmented pet consumption, small pet feed production machines, with their significant cost advantages, flexible production characteristics, and efficient return cycles, provide industry participants with both economically viable and feasible solutions. Whether entering new markets or incubating niche product lines, such equipment has become the golden ticket to the pet food industry.

Analysis of Core Equipment Advantages

Small pet food production equipment has become the preferred choice for entrepreneurs due to its comprehensive advantages in intelligence, production efficiency, nutrient retention, energy saving and environmental protection, as well as ease of maintenance. Below is a deep analysis of its technical highlights from five dimensions:

1.Intelligence: The equipment is equipped with advanced automated control systems that can monitor and manage the entire process from raw material input to finished product output. Using smart sensors and data analysis, it adjusts production parameters in real-time to ensure the stability and consistency of feed quality. Additionally, users can remotely monitor and operate the equipment via smartphones or computers, significantly enhancing production flexibility and response speed. The intuitive user interface allows for seamless operation even by personnel with minimal training, while the integrated AI algorithms predict maintenance needs and optimize performance.

2.Production Efficiency: Utilizing high-efficiency mixing, pelletizing, and cooling technologies, small pet food production equipment can produce large quantities within a short time, meeting market demand. Its modular design makes it easy to expand and upgrade, allowing flexible adjustment of production capacity according to changes in scale. The streamlined workflow minimizes downtime between batches, ensuring continuous production and maximizing throughput.

3.Nutrient Retention: The equipment uses low-temperature processing technology to maximize the retention of nutrients such as proteins, vitamins, and minerals in raw materials. Moreover, precise formula control and uniform mixing ensure balanced nutrition in each batch of feed, meeting the growth and health needs of pets. The gentle processing techniques preserve the natural flavors and aromas of the ingredients, making the feed more appealing to pets.

4.Energy Saving and Environmental Protection: The equipment employs energy-saving motors and optimized thermal recovery systems, significantly reducing energy consumption. Furthermore, it is equipped with efficient dust removal and exhaust gas treatment devices, minimizing environmental impact and meeting green and environmental protection requirements. The noise reduction features ensure a quieter operating environment, contributing to a safer and more pleasant workplace.

5.Maintenance Convenience: The equipment is designed with ease of maintenance in mind, featuring modular structures for key components that facilitate disassembly and replacement. Additionally, it includes a self-diagnostic system for faults, promptly identifying and alerting potential issues, reducing downtime, and lowering maintenance costs. Regular maintenance alerts and detailed troubleshooting guides are available through the integrated software, ensuring optimal operational uptime.

Production Process

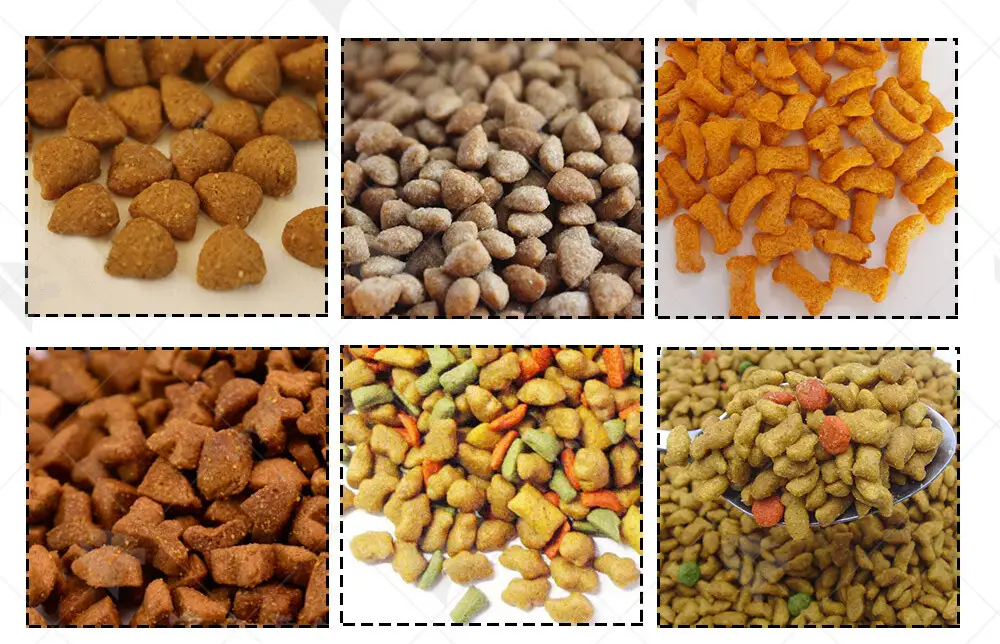

Modern pet food production lines utilize highly automated processes, from raw material mixing to finished product packaging, with each stage precisely controlled to ensure the final product is nutritionally balanced, safe, and reliable.

The production process begins with the mixing stage, where various raw materials, rigorously selected, are added to large twin-shaft paddle mixers according to scientific ratios. This mixing equipment features a unique stirring design that can uniformly mix protein ingredients, grains, and vitamin premixes within 3-5 minutes, achieving a mixing uniformity of over 95%, ensuring that each pellet contains balanced nutritional components. The mixed raw materials are then smoothly conveyed to the next stage via closed-spiral conveyors, which effectively prevent cross-contamination during transportation. Metal detection and magnetic separation devices are also installed during conveyance to promptly remove any potential metal impurities. Subsequently, the raw materials enter the core twin-screw extrusion puffing system, where they undergo high-temperature and high-pressure physical and chemical changes. The extruder barrel is divided into multiple temperature-controlled zones, with precise adjustments made to temperature (90-150℃), pressure (20-40 bar), and screw speed to fully gelatinize starch and moderately denature proteins, ultimately forming porous structured pellets. This stage directly determines the digestibility and palatability of the feed.

The semi-finished product, after being puffed, is conveyed into a multi-layer belt dryer by a bucket elevator for drying. The drying process uses segmented temperature control technology, with high temperatures initially to quickly remove moisture, followed by low temperatures to slowly dry the material, reducing the moisture content from 25-30% to 8-10%. A specially designed air circulation system ensures that hot air evenly penetrates the material layer, preventing areas from becoming too dry or too moist. Next, the product enters a countercurrent cooling tower, where room temperature air is blown upward from the bottom by cooling fans, creating a countercurrent heat exchange with the falling hot particles. This design not only enhances cooling efficiency but also effectively reduces product breakage.

After cooling, the product is once again conveyed by the elevator to the seasoning process, where it is evenly sprayed with specially formulated flavor oils or nutrient solutions using an oil sprayer. This equipment uses a high-pressure atomization system combined with a spiral mixing device, ensuring that each particle of feed is coated uniformly. The high-pressure atomization system breaks down the oils and solutions into fine mist droplets, which seamlessly adhere to the feed particles. The spiral mixing device then gently tumbles and rotates the feed, ensuring an even and thorough coating. This meticulous process enhances palatability, making the feed more appealing to animals, while also supplementing essential fatty acids crucial for their overall health and nutrition. The aroma of the freshly sprayed flavors wafts through the air, creating a tantalizing scent that hints at the enhanced nutritional benefits awaiting the consumers.

Finally, the finished product enters an automated packaging production line. Advanced electronic quantitative packers use combination scales for measurement, achieving precision up to ±1 gram. The packaging process is carried out in a clean environment, automatically completing tasks such as bag making, filling, vacuum sealing, nitrogen flushing for freshness preservation, and sealing. The entire production process, from raw materials to finished products, takes about 2-3 hours, with the central control system monitoring the whole process to ensure that each process parameter strictly meets quality standards, ultimately producing high-quality pet food that is nutritionally balanced, safe, and reliable.

Technical Parameters Of Pet Food Extruder Machine For Sale

Model | Installed Power | Power Consumption | Output | Size (L*W*H) |

PFE-65-1 | 80kw | 56kw | 120--150kg/h | 22500x1200x2200mm |

PFE-70-1 | 128kw | 90kw | 200-250kg/h | 25000x1500x2200mm |

PFE-85-1 | 175kw | 123kw | 300-600kg/h | 30000x3500x4300mm |

PFE-90-1 | 287kw | 216kw | 1000-1200kg/h | 40000x2400x4000mm |

PFE-75-2 | 186kw | 139.5kw | 300-600kg/h | 24000*2000*2800 |

PFE-95-2 | 383kw | 287kw | 1000-1500kg/h | 40000*3000*4000mm |

PFE-115-3 | 424kw | 318kw | 2T-3Tg/h | 42000x3000x4000mm |

PFE-130-3 | 502kw | 376kw | 4T-5Tkg/h | 46000*3000*4000mm |

FAQ:

①What is the production capacity of this production line, and what size of enterprise is it suitable for?

A: •Standard capacity: 100kg/h-1000kg/h (customizable small or extra-large equipment).

• Suitable customers:

◦Small and medium-sized enterprises: 100-250kg/h modle, low investment threshold, suitable for start-up brands or contract manufacturers.

◦Large enterprises: 300-1000kg/h, fully automated design, suitable for bulk exports or chain brands.

②Does the equipment meet food safety certification requirements?

A: Certifications: CE, FDA, ISO 22000 certifications.

Material Safety: All parts that come into contact with food are made of 304 stainless steel, eliminating any risk of contamination.

③What does after-sales service include?

A: • Basic services:

◦ Free installation and commissioning + operation training

◦ 1-year full machine warranty

• Value-added services (optional):

◦ Remote monitoring system (real-time fault diagnosis)

◦ Annual maintenance plan

④How automated is the production line? Is it necessary to have a technician operate it?

A: • Automation level:

◦ The entire process from raw material input to packaging is fully automated, requiring only manual input of raw materials and random inspections.

◦ Touchscreen control allows for one-button start-up after parameter settings.

• Operational difficulty:

◦ Ordinary workers can be trained to operate within 1 to 3 days.

◦ We provide operation manuals in both Chinese and English along with a fault code guide.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/