Next-Gen Efficiency: Microwave Defrost Machine for Automated Pasta Processing

Introduction

In the ever-evolving landscape of food production, the evolution of defrosting technology stands out as a pivotal aspect. The demand for efficiency has driven continuous advancements, leading to the emergence of cutting-edge solutions. Among these, the Next-Gen Microwave Defrost Machine has positioned itself as a game-changer, particularly in the context of automated pasta processing.Our company's microwave thawing technology draws inspiration from the advanced techniques pioneered by Thermex-Thermatron Systems and Ispecc.

Efficient defrosting holds paramount significance in the realm of automated pasta processing. The intricacies of pasta production demand precision at every stage, and the defrosting process is no exception. The speed and quality of defrosting directly influence the overall efficiency of the automated system, making it a key factor in ensuring seamless operations.

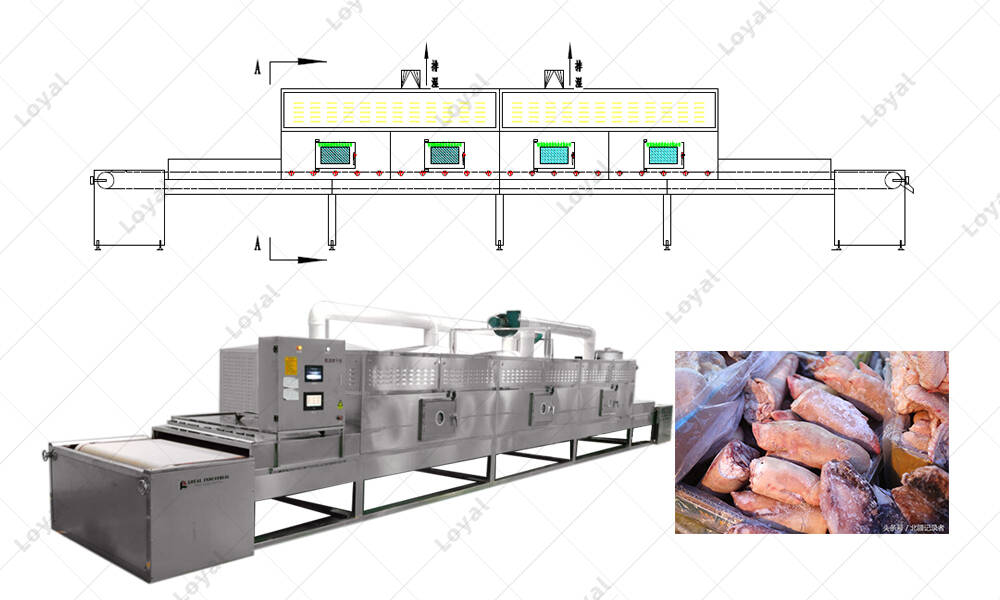

At the heart of this article is the introduction of the Next-Gen Microwave Defrost Machine. This innovative machinery represents the pinnacle of defrosting technology, integrating advanced features designed to revolutionize the way pasta processing lines operate. As we delve into its cutting-edge features, the transformative impact on automated pasta processing becomes evident.

Cutting-Edge Features of the Microwave Defrost Machine

Boldly embracing advanced microwave technology, the Next-Gen Microwave Defrost Machine sets itself apart with its ability to rapidly and uniformly defrost ingredients. The utilization of precise frequencies ensures optimal results, catering specifically to the requirements of automated pasta processing. This advanced technology forms the cornerstone of the machine's efficiency.

Integration with automated pasta processing lines is a defining feature of this machine. Seamless compatibility allows for a synchronized workflow, where the defrosting process aligns perfectly with other production stages. This level of automation not only accelerates the overall pasta production but also enhances the overall efficiency of the processing line.

Smart monitoring and control systems elevate the operational intelligence of the Next-Gen Microwave Defrost Machine. Real-time data analytics enable manufacturers to fine-tune the defrosting parameters based on specific pasta recipes and production requirements. The precision offered by these systems contributes to consistent and high-quality results.

In an era where sustainability is a key concern, the energy-efficient design of the machine aligns with global environmental goals. The Next-Gen Microwave Defrost Machine minimizes energy consumption during the defrosting process, making it not only efficient but also environmentally conscious.

Advantages of Next-Gen Microwave Defrost Machine

The Next-Gen Microwave Defrost Machine brings a paradigm shift to pasta production by significantly accelerating the defrosting process. Reduced defrosting times translate to shorter production cycles, meeting market demands with unparalleled efficiency. This advantage positions manufacturers at the forefront of the competitive pasta industry.

Efficiency doesn't come at the cost of quality. The machine excels in preserving the texture, flavor, and nutritional value of pasta ingredients during the defrosting process. The uniform thawing achieved ensures that each batch of pasta maintains the highest quality standards, meeting the discerning expectations of consumers.

Beyond immediate benefits, the operational cost savings achieved through the efficiency of the Next-Gen Microwave Defrost Machine are noteworthy. Streamlined production processes, coupled with energy-efficient design, contribute to a reduction in operational costs. This economic advantage adds strategic value to the adoption of this innovative technology.

Seamless Integration into Automated Pasta Processing

The seamless integration of microwave defrosting into automated pasta lines enhances overall production efficiency. The Next-Gen Microwave Defrost Machine aligns with the intricacies of pasta manufacturing, ensuring that each ingredient is swiftly and uniformly prepared for subsequent processing steps. This integration is a crucial factor in achieving a streamlined and synchronized workflow.

The impact on production timelines is significant. By substantially reducing defrosting times, the machine contributes to an accelerated pasta production cycle. This not only meets market demands more efficiently but also provides manufacturers with a competitive edge in delivering fresh and high-quality pasta products to consumers.

Quality enhancement is a natural outcome of the machine's efficient defrosting process. The uniform thawing achieved by the Next-Gen Microwave Defrost Machine reflects directly in the quality of the pasta produced. Consistency becomes a hallmark, ensuring that each batch meets the highest standards set by discerning consumers.

Case Studies and Success Stories

To substantiate the practical benefits of the Next-Gen Microwave Defrost Machine, let's explore real-world case studies. Pasta facilities adopting this innovative technology report remarkable improvements in overall production processes. Reduced defrosting times lead to increased operational efficiency, with manufacturers noting positive impacts on the quality of their pasta products.

The tangible outcomes extend beyond mere efficiency. Pasta facilities leveraging the Next-Gen Microwave Defrost Machine report a noticeable increase in throughput and yield. This not only translates to higher profits but also positions these manufacturers as industry leaders committed to embracing technological advancements.

Addressing Challenges and Innovative Solutions

Acknowledging the nuanced nature of food manufacturing, the article delves into potential challenges associated with microwave defrosting. Whether it's uneven thawing or concerns about texture alterations, the Next-Gen Microwave Defrost Machine is designed with solutions that mitigate these challenges effectively. Proactive measures ensure a smooth and reliable performance.

To ensure the sustained performance of the machine, proper maintenance practices and troubleshooting protocols are imperative. This section offers insights into best practices for maintaining the Next-Gen Microwave Defrost Machine, emphasizing the importance of regular checks and prompt issue resolution. Proactive maintenance ensures optimal performance, minimizing downtime.

Future Trends and Innovations in Microwave Defrost Technology

As the food industry continually evolves, ongoing research in microwave defrosting promises further breakthroughs. This section provides a glimpse into the cutting-edge innovations that researchers are exploring, hinting at advancements that may redefine the landscape of automated pasta processing.

Anticipating the future trajectory of microwave defrost technology, we delve into potential industry developments. From enhanced automation to integration with artificial intelligence, the article paints a picture of the exciting possibilities that lie ahead. The Next-Gen Microwave Defrost Machine is positioned as a catalyst for future advancements in automated pasta processing.

Conclusion

In summary, the Next-Gen Microwave Defrost Machine delivers unprecedented efficiency to automated pasta processing. The evolution of defrosting technology, its seamless integration, and the myriad advantages it brings collectively position this machine as an indispensable tool for manufacturers seeking to stay ahead in a competitive market.

As we conclude, it's evident that the Next-Gen Microwave Defrost Machine is not just a technological innovation; it's a catalyst shaping the future of automated pasta processing. With accelerated production, enhanced quality, and a commitment to sustainability, this machine is set to redefine industry standards. Manufacturers embracing this technology are not merely adopting a solution; they are ushering in a new era of efficiency and excellence in the automated pasta processing landscape.