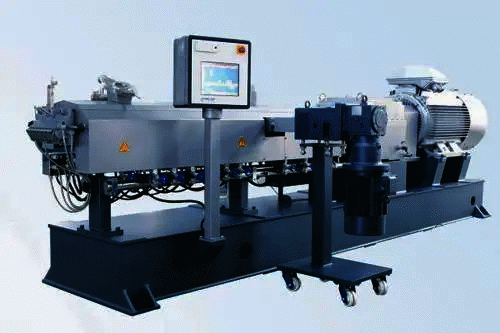

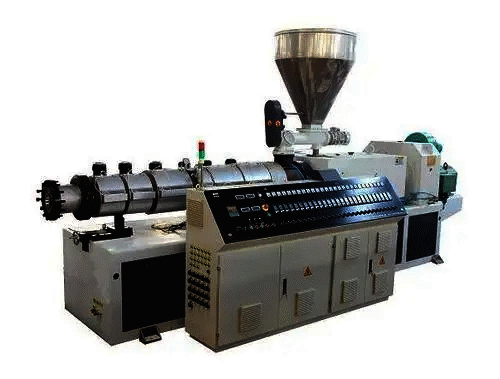

How to maintain and troubleshoot the twin screw extruder machine?

When processing materials, it is necessary to obtain the energy required for physical changes and partial chemical changes to complete the processing.

The most commonly used machine is the Twin Screw Extruder Machine.

Which can make the distribution of components evenly and initially dispersed. The components are homogenized, the viscosity is close, and the performance is very good.

When using a twin-screw extruder, the operator must follow the correct operation steps and pay attention to maintaining it at ordinary times.

Keeping the extruder clean can produce better products and reduce the occurrence of failures.

To ensure the continuous production, then how to maintain the twin-screw extruder when it is in use? Let's take everyone to find out.

Daily maintenance of twin screw extruder:

1.The basic maintenance is to clean the machine and lubricate the moving parts of the twin-screw extruder. For example, there will be iron filings or other impurities from the gears in the gearbox.

At this time, check the wear of gears and bearings and make a record. Clean the gears and regularly replace the gearbox lubricating oil.

2.After using for a period of time, conduct a comprehensive inspection of the twin-screw extruder, check the looseness of all screws.

And make inspection records at the same time, and tighten the screws that are easy to loosen to prevent the twin-screw extruder from malfunctioning. .

3. Check and adjust the motor, control instrument and other pipelines and working parts of the twin-screw extruder. If there is a sudden power failure during production, the main rotation and heating will stop.

When the power supply is restored, each section of the barrel must be reheated to Start the extruder equipment after the specified temperature and keep it warm for a period of time.

4. The inner wall of the cooling water pipe attached to the twin-screw extruder is prone to scale.

And the outside is easy to rust and corrode. It should be checked during maintenance. Excessive scale will block the pipeline and fail to achieve the cooling effect.

The rust is serious and it is easy to leak. Descaling and anti-corrosion and cooling measures must be taken during maintenance.

Knowing the daily maintenance work of the twin-screw extruder,veryone pays attention to these aspects at ordinary times can prolong the service life of the extruder and produce high-quality products.

In addition, in the process of use, twin-screw extruders will also have such problems, and failures are inevitable. Let's talk about common failures of extruders and their solutions.

1. The host current is unstable

The causes of this failure include uneven feeding, damage to the main motor bearing or poor lubrication, a certain section of heater failure, no heating, wrong screw adjustment pad or wrong phase, component interference.

The treatment method is to check the feeder, eliminate the fault, repair the main motor, replace the bearing if necessary, check whether the heaters are working normally, and replace the heaters if necessary.

Check the adjustment pad and pull out the screw to check if there is any interference in the screw.

2. The head pressure is unstable

The cause of this fault is the uneven speed of the main motor, or the uneven speed of the feeding motor, and the feeding amount fluctuates.

The solution to this problem is to check the main motor control system and bearings, and check the feeding system motor and control system.

3. Low lubricating oil pressure

The cause of this failure is that the pressure setting value of the pressure regulating valve of the lubricating oil system is too low, the oil pump is faulty or the oil suction pipe is blocked.

The solution to this problem is to check and adjust the pressure regulating valve of the lubricating oil system, check the oil pump and the oil suction pipe.

4. The main motor cannot be started

There is an error in the driving procedure. There is a problem with the main motor thread, whether the fuse is burned. The solution is to check the procedures and restart the car in the correct driving sequence. Check the main motor circuit.

Check whether the lubricating oil pump is started.

And check the status of the interlocking device related to the main motor.

If the inverter has not discharged the induction current, turn off the main power supply .

And wait for five minutes before starting. Check whether the emergency button is reset.

The above is the related introduction to the maintenance and fault maintenance of Twin Screw Extruder Machine.

I believe that everyone has a certain understanding after reading it. When you use it, you can maintain and repair the extruder according to these methods. I hope these contents are correct You are helpful.