How do you process soya meat?

Soya meat is a prevalent vegetarian food. With its very rich protein content and a taste very similar to animal meat, it has become one of the most popular foods for consumers. It is also considered to be a very healthy food with high nutritional value and low-fat content, making it a perfect substitute for animal meat and a popular choice for a healthy diet.

Although soya meat has been very common in our daily lives, do you know how soybean meat is processed?

How do you process soya meat?

Soya meat is produced with soya protein, peanut protein, and other major raw materials, using extrusion and puffing technology, so that the production cost of soya meat is relatively low. The composition is natural, with unsaturated fatty acid content and other health advantages. In the flavor, texture, and other aspects are close to the real meat, after years of market testing proved that soya meat is very consistent with the dietary needs of modern consumers.

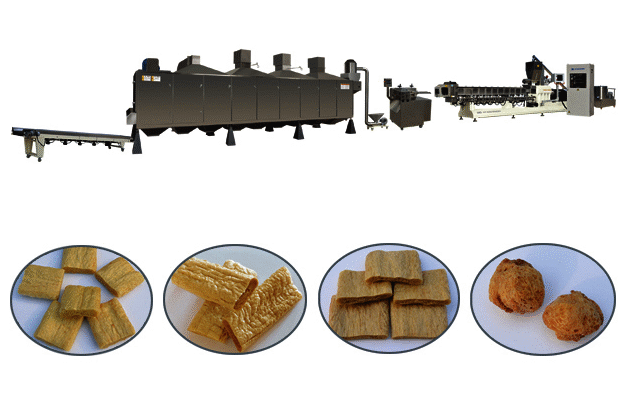

The specific production process of soya meat is shown below:

In order to produce high-quality soya meat, it is necessary to use raw materials of relatively reliable quality, and soya protein is the best choice. Soybeans obtain soya protein isolate or soy protein concentrate by defatting and partially or completely removing carbohydrates. After processing such as hydration, high-temperature extrusion, and mechanical shearing, the protein is denatured, and the internal molecular spatial structure is rearranged and distributed to obtain a Layered, fibrous organizational structure.

The extruder is one of the most important equipment in the production of soya meat. The application of extrusion technology is also the key to the production of soya meat, which is currently the most common production and processing method for the production of soya meat.

The extrusion process integrates the mixing of raw materials, homogenization, maturation, molding, and other unit operations in one. The raw material is conveyed and compressed by the screw and is subjected to the dual action of shear and friction in the heated barrel to form a molten fluid. In the process of continuous forward, the raw materials are at high temperature and pressure, and the protein will be denatured. When the raw materials are extruded through the die, in the direction of flow under the role of a certain degree of When the raw material is extruded through the die, a certain degree of fibrous structure is formed by the directional flow.

The shape of the die is optional, and we can provide many different shapes of dies and custom-made dies for manufacturers according to their needs, trying to meet all their needs.

The bean meat produced in this way is rich in protein. Compared with traditional animal protein, vegetable protein is cholesterol-free, low-fat, and low-calorie, making it a healthy food, which now has huge market potential.

The increase in market demand attracts more manufacturers to start producing soya meat, and the competition is getting fierce, so manufacturers can only improve their production level to get a broader market.

Soya Meat Making Machine realizes a highly automated production method. You only need to set up the program in advance to achieve 24h continuous production. The production is simple, efficient, and very convenient, and the operation is also very simple.

The Soya Meat Making Machine is made of food-grade stainless steel and has the most advanced extrusion process. It protects the proteins in the raw material from being destroyed and retains most of the nutrients, and produces bean meat with very high-quality standards. The machine is long-lasting, meets national health quality standards, and is inexpensive, which is very beneficial for small and medium-sized enterprises.

Soybean meat has been recognized by the public and has high market demand. I believe that with our efforts, we will further promote the development of the food processing industry and provide consumers with more nutritious and healthy, and delicious food!