Analysis of Industrial Macaroni Pasta Production Line

Thanks to its affordability and versatility in the kitchen, pasta makes up a staple in the average diet in many western countries. In fact, Pasta provides you with energy, as well as essential nutrients in the form of fiber, vitamins and minerals. Pair your pasta with healthful ingredients to prepare nutrient-packed meals. The traditional pasta production process is relatively more primitive and complicated; it is thought to have certain drawbacks. In recent years, with the advancement of science and technology, continuous improvements have been made in the macaroni pasta production process, and new types of pasta production equipment have also emerged consistently.

The Industrial pasta processing equipment has significantly enhanced the technology and made the process more effective, successfully eliminating some traditional drawbacks. That is being said, the production line has the characteristics of a high degree of automation, good stability, convenient operation, large output within in short working time. Besides, it can process a variety of raw materials such as corn starch, potato starch, wheat flour, etc., and has a very wide range of applications. It is exceptionally versatile and can realize multiple uses in one machine, and is able to save investment costs tremendously.

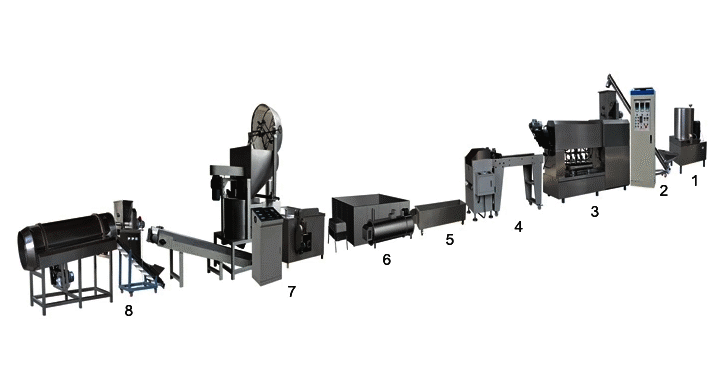

As shown in the figure, the Industrial Macaroni Pasta Production Line has easonable design, compact structure. The entire production line is completed at one time from raw material mixing, extrusion molding, cooling and packaging. It has a high degree of automation. Besides, it only requires one to two people to complete the whole processing and production line. Therefore, manpower is significantly saved to a large extent, and work efficiency has been significantly improved.

Features of industrial macaroni production line:

1. The production line has high degree of automation, convenient operation and low investment cost.

2. The energy consumption is very low, and the floor space is small, which guarantees all the processes from powder application to completion.

3. Advanced frequency control technicians ensure stable work and less power consumption.

4. It is developed according to similar products and requirements in the international market, with compact structure, novel design and stable performance.

5. The investment of this production line is only one-tenth of that of large-scale equipment, and the cost is low. Especially suitable for small or self-owned enterprises.

Technical parameters of industrial macaroni production line:

Input voltage | 380 V/50Hz, 3 phase |

Installed power | 89.6 kW |

Energy consumption | 60 kW |

Capacity (output) | 100-150 kg/hour |

Installation size | 20000 X 5000 X 2400 mm |

Manpower required | Macaroni: 1-2 workers |

The above are the equipment technical parameters for reference. It can be seen from the table that the technical performance of the production line is excellent, with a low level of energy consumption while maintaining a high standard of work efficiency. Besides, the floor space is small, and the operation requires few workers, and super user-friendly.

The price of this production line is also very reasonable, believe it or not, the fact is that you don't have to spend too much money to buy high-quality equipment, which is outstanding value for money.

The Industrial Macaroni Pasta Production Line uses wheat flour as raw material Without any additives. Besides, it is capable of manufacturing a variety of pasta in different shapes and colors. At present, wheat flour with appropriate proportions of tartary buckwheat flour and sweet water chestnut flour is used as raw materials, furthermore, with the pasta production line. There are two new products that have been successfully developed currently, respectively Kumang Macaroni and Sweet Soba Macaroni.

Driven by science and technology, the industrial pasta production line has also been continuously improved, and its functions have become more and more perfect, with a wider range of applications, and it can produce a variety of types of pasta. Furthermore, the products produced are very high-quality and healthy. During the production process, no pollutants are produced. At the same time, the original nutrition of the food is maintained maximally.