Microwave sterilization

I. Concept

Food products are highly susceptible to contamination and deterioration during production, preservation, transportation and distribution. Usually high temperature, drying, scalding, pasteurization, freezing and preservatives can be used to achieve the sterilization and preservation of food, but often affect the original flavor and nutrients of food. Microwave insecticidal sterilization is to make the microorganisms in food, while the combined effect of microwave thermal and non-thermal effects, so that its body proteins and physiological activities of the material mutation, resulting in the growth and development of microbial slowdown and death, to achieve the purpose of food sterilization, preservation.

II. Principle

1. The Thermal Effect Of Microwave Energy: under the action of a certain intensity of microwave field, the insects and bacteria in food will be due to the phenomenon of molecular polarization, absorption of microwave energy to warm up, so that its protein denaturation, loss of biological activity. The thermal effect of microwaves mainly plays a rapid role in sterilization.

2. Non-Thermal Effect Of Microwave Energy: the high frequency electric field also makes its membrane potential, polar molecular structure changes, so that the microbial body proteins and physiologically active substances mutated, and loss of vitality or death. In the sterilization played a special role in the conventional physical sterilization is not, but also caused one of the causes of bacterial death.

3. Microwave sterilization, preservation is the result of the combined effect of microwave thermal and non-thermal effects. Therefore, microwave sterilization temperature is lower than conventional methods, in general, the conventional method sterilization temperature to 120 ℃ -130 ℃, about 1 hour, while the microwave sterilization temperature of only 70 ℃ -105 ℃, about 90-180 seconds.

III. Advantages

1. Short Time, Fast

Conventional thermal sterilization is through heat conduction, convection or radiation and other ways to transfer heat from the food surface to the interior. To reach the sterilization temperature, it often takes a long time. Microwave sterilization is a direct interaction between microwave energy and food and its bacteria and other microorganisms, the thermal and non-thermal effects work together to achieve rapid temperature sterilization effect, the processing time is greatly shortened, the sterilization of various materials in general 3-5 minutes.

2. Low-Temperature Sterilization To Maintain Nutrients And Traditional Flavor

Microwave sterilization is sterilized by special thermal and non-thermal effects, compared with conventional thermal sterilization, can be at a relatively low temperature and a shorter period of time to obtain the required sterilization effect. Practice shows that the general sterilization temperature at 75-80 ℃ can achieve the effect, in addition, microwave treatment of food can retain more nutrients and color, fragrance, taste, shape and other flavor, and puffing effect. Such as conventional heat treatment of vegetables to retain the vitamin C is 46-50%, while the microwave treatment is 60-90%, conventional heating of pork liver vitamin A to maintain 58%, while microwave heating for 84%.

3. Saving Energy

Conventional heat sterilization often in the environment and equipment heat loss, while the microwave is a direct role in the treatment of food, and thus no additional heat loss. In addition, its electrical energy to microwave energy conversion efficiency in 70-80%, compared to the general power savings of 30-50%.

4.Surface And Internal Are Carried Out At The Same Time

Conventional thermal sterilization is started from the surface of the material, and then through heat transfer to the internal, there is an internal and external temperature difference. In order to maintain the flavor of food, shorten the processing time, often the internal temperature of food does not reach enough to affect the sterilization effect. Because of the penetrating effect of microwaves, the overall treatment of food, the surface and internal are simultaneously affected by the action, so the sterilization is uniform and thorough.

5.Easy To Control

Microwave food sterilization treatment, the equipment can be ready to use, no conventional thermal sterilization of thermal inertia, flexible and convenient operation, microwave power can be continuously adjustable from zero to rated power, transmission speed from zero to continuously adjust, easy to control.

6.Simple Equipment, Advanced Technology

Compared with conventional sterilization, microwave sterilization equipment, no boiler, complex piping systems, coal yards and transport vehicles, etc., as long as the basic conditions of water and electricity can be.

7. Improve Labor Conditions, Save Floor Space

The working environment of the equipment is low temperature and low noise, which greatly improves the labor conditions. Only 2-3 operators are needed for the whole set of microwave equipment. Widely used in the warming, drying and sterilization of beef jerky, dried pork, fish slices, fontina meat, duck meat, chicken and other products. Meat products by microwave sterilization, its freshness, tenderness, flavor are maintained as is, health indicators can be completely below the national food hygiene standards, shelf storage time up to 1-2 months, microwave sterilization of meat products, the successful application of preservation technology, from the original freshness period of 3 days, extended to 1-2 months, has improved the technical achievements to a new stage.

Iv. Application Objects

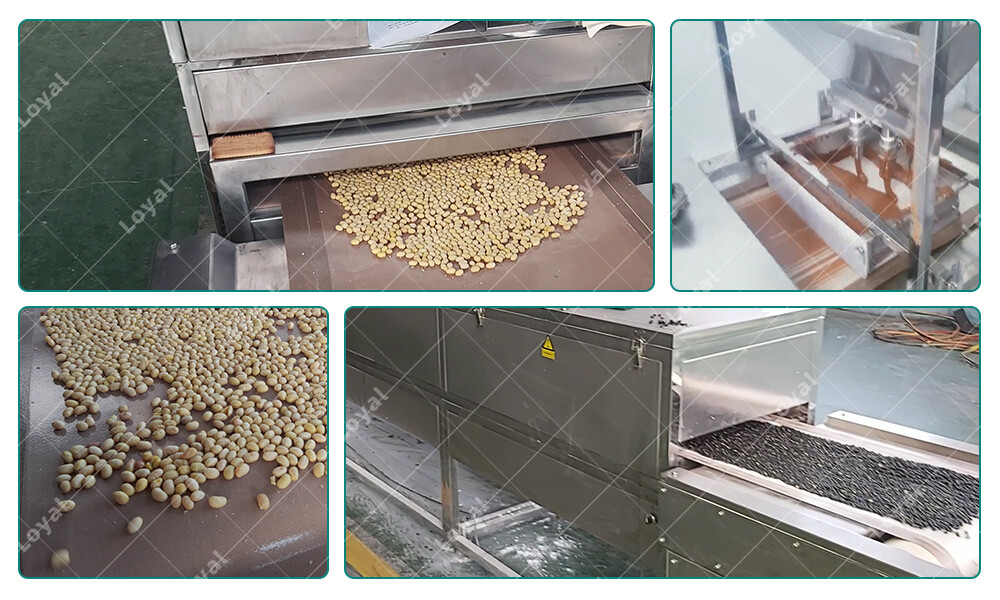

Microwave equipment can be used for sterilization of packaged and unpackaged items.

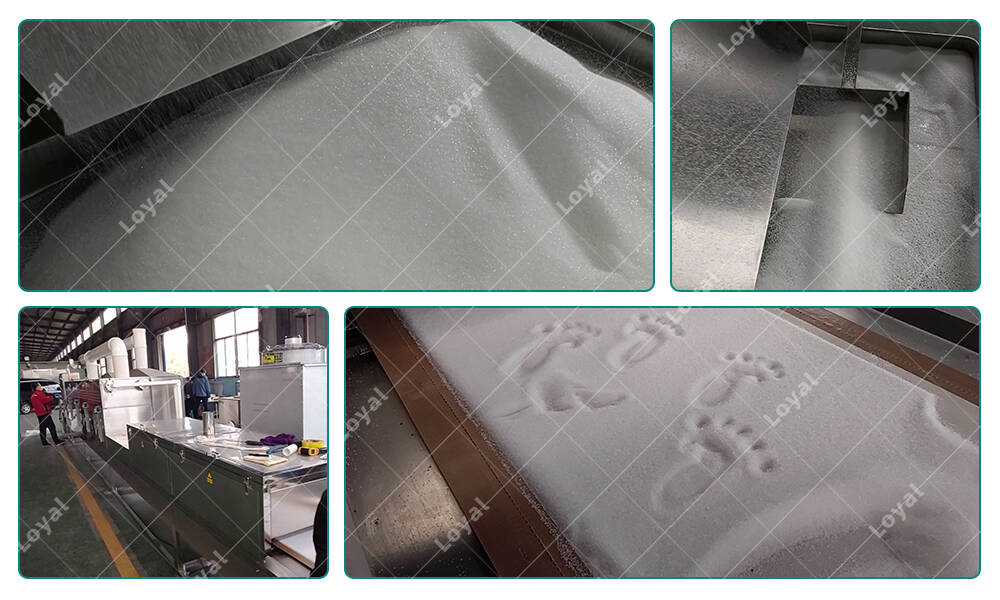

Grain products: bread, moon cake, noodles, tofu, dried tofu, etc.

Vegetables: kimchi, bamboo shoots, shiitake mushrooms, etc.

Fruits: lychee, longan, etc.

Dairy products, spices, flavors and fragrances, instant noodle soup, hot pot seasoning and various liquids can be sterilized and processed.