PLC Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine

PLC Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine is a high-frequency electromagnetic wave machine, which can instantly radiate through cocoa beans, pistachios and other nuts and grains, produce thermal effects and biological effects, and achieve the function of Industrial Microwave cocoa bean drying, as well as puffing, sterilization, drying, mildew prevention, etc. The microwave of the cocoa drying machine is not inert to the heating of the material, that is, as long as there is microwave radiation, the material will be heated immediately. Microwave drying is widely used in the drying of cocoa beans. Because microwaves have longer wavelengths, they have better penetration. The use of microwaves to extract natural pigments has the advantages of high extraction rate, time saving, low energy consumption, safety, and easy process control, which is beneficial to industrial production. It is suitable for microwave extraction and preparation of pectin, high viscosity chitosan and plant essential oils.

PLC Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine Specifications :

| Price | Check with Microwave Drying Machine Team Saler |

| Brand Name | Loyal Microwave Drying Machine |

| Model Number | Cocoa Beans Microwave Drying Machine |

| Place of Origin | China |

| Min.Order Quantity | 1set of Microwave Equipment |

| Payment Terms | TT |

| Supply Ability | 20Days of Microwave Equipment |

| Team | Microwave Drying Sterilizing Machine Technical Team |

| Sales Team | Microwave Drying Sterilizing Machine Process Technology Engineer |

| Processing Technology | Microwave Drying Sterilizing Machine Process Technology |

PLC Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine Detail Introduction :

PLC Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine is a high-frequency electromagnetic wave machine, which can instantly radiate through cocoa beans, pistachios and other nuts and grains, produce thermal effects and biological effects, and achieve the function of Industrial Microwave cocoa bean drying, as well as puffing, sterilization, drying, mildew prevention, etc. Features.

Introduction Of Plc Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine

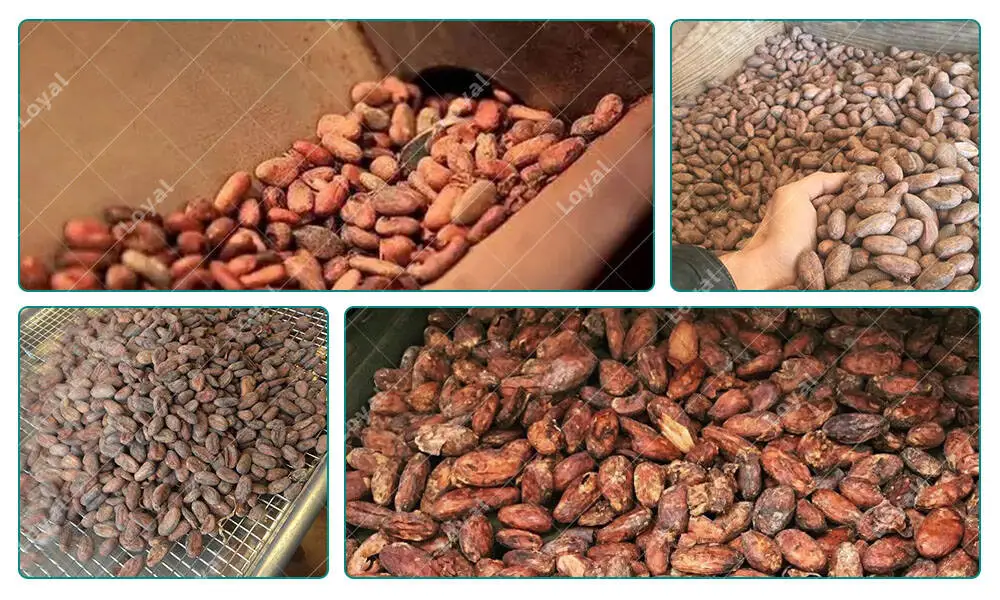

Cocoa beans are mainly used in the manufacture of various chocolate candies and beverages. Cocoa beans are also used to produce non-food products such as pharmaceuticals, cosmetics and toiletries. Cocoa beans need to be fermented and dried after harvesting. The main fermentation methods are stacking fermentation and box fermentation. The drying methods are divided into natural drying and Industrial Microwave drying the cocoa seeds. The microwave of the cocoa drying machine is not inert to the heating of the material, that is, as long as there is microwave radiation, the material will be heated immediately. Microwave drying is widely used in the drying of cocoa beans. Because microwaves have longer wavelengths, they have better penetration.

How Long Does It Take To Dry Out Cocoa Beans?

Microwaves can directly generate heat from the molecules inside the food. When the microwaves are surrounded by metal, the energy in them is sealed and only acts on the heated material, no heat transfer medium is needed, and the energy utilization rate is high. Nestle uses 2450MHz, 10kW microwave equipment to roast cocoa beans, and the processing time is 5~10min, which is half of the traditional roasting time.

What’s the price of Plc Control Conveyor Mesh Belt Dryer Cocoa Beans Microwave Drying Machine

| Cocoa beans microwave tunnel drying machine/high quality continuous tunnel microwave dryer machine industrial microwave dryer | |

| 1. Product model | Ly-30hm5 |

| 2. Microwave frequency | 2450mhz±25hz |

| 3. Microwave output power | 30kw (adjustable in sections) |

| 4. Rated input power | ≤45kva |

| 5. Types of microwave suppressors | Reactive + resistive leakage suppressor |

| 6. Microwave field | High-q resonant system |

| 7. Microwave feed | Multimode coupling |

| 8. Microwave device cooling method | Air-cooled/water-cooled |

| 9. Video surveillance system | Clearly and intuitively understand the running status of materials |

| 10. Conveyor belt width | 660mm |

| 11. Dimensions (l×w×h) | About 9400×1215×1650mm |

| 20000usd |

| The industrial tunnel microwave coffee cocoa bean roasting dryer machine price is a promotional price in 2022, update price. Check with our industrial microwave cocoa bean drying machine team. | |

How do Chinese dry cocoa beans?

The technology of cocoa beans drying machine provides a new heating method for industrial heating, which has been widely used in industry, agriculture, chemical industry, medical treatment and so on. The first is to use its thermal effect, which is mainly used for drying cacao beans, microwave drying and sterilization of food, microwave drying and sterilization of medicinal materials, microwave sterilization of agricultural and sideline native products, microwave drying of wood, microwave drying of cardboard, chemical industry products, etc. Forming and sintering, microwave vulcanization preheating of rubber, etc. Second, Cocoa Beans Microwave Tunnel Drying Machine utilizes its biological effects to sterilize food, medicinal materials, agricultural and sideline native products at low temperature by microwave, prevent mildew and preserve freshness, and use microwave to accelerate aging, alcoholization, suspension of fermentation, and breeding of liquor.

| Technology for PLC control conveyor mesh belt dryer cocoa beans microwave drying machine | |

| 1. Application of cocoa beans drying machine technology in microwave roasting and roasting of food | Cocoa beans are roasted by microwave equipment, and the processing time is 5~10min, which is half the time compared with traditional roasting; the use of microwave proofing dough in bread production can shorten the proofing time; microwave roasting has been successfully used for bacon, meat patties and poultry it can not only shorten the processing time, reduce the production cost, but also improve the yield and the preservation of the product. |

| 2. Application of microwave cocoa beans drying machine technology in drying | Used for drying potato chips, noodles, condiments, snacks, seafood, vegetables, fruit powder, egg yolk powder, ginseng honeysuckle, dried meat, dried meat, mushrooms, tea and other varieties. It can better maintain the color, aroma, taste and nutrient content of materials, and has unique sterilization advantages, which is conducive to product storage. |

| 3. Application of microwave cocoa beans drying machine technology in food sterilization | To achieve the same sterilization effect, the microwave technology requires only 1/9~1/2 of the traditional heating time. 50°c can not only kill the microorganisms in the vacuum-packed beef, but also maintain the apparent characteristics of fresh meat. ; soy sauce can inhibit the growth of mold and kill intestinal pathogenic bacteria after 6min of microwave treatment at 2450mhz; it can also microwave sterilize beer, and the flavor of beer is kept well. For puffed aleurone food, the temperature of the material can reach 80~90°c after processing for 20s, and the sterilization effect is extremely significant. |

| 4. Application of microwave technology in food separation engineering | The use of microwaves to extract natural pigments has the advantages of high extraction rate, time saving, low energy consumption, safety, and easy process control, which is beneficial to industrial production. It is suitable for microwave extraction and preparation of pectin, high viscosity chitosan and plant essential oils; microwave technology is used to promote the ripening and aging of wine, fermented products and chocolate, the synthesis of food additives, tea greening, fruit and vegetable blanching, food conditioning it also has good application effects in terms of temperature and thawing. |

Customer Cases For Cocoa Beans Microwave Tunnel Drying Machine For Factory In 2021

Shandong Loyal Industrial relies on complete product specifications, excellent product quality and professional services. It has been widely recognized by customers, obtained a good brand image, has mature and stable sales channels, and accumulated a large number of high-quality customers. At present, the company's products are in short supply and are exported to Asia, Europe, North America, Africa, South America and Oceania, with customers in more than 50 countries and regions around the world. If you are interested in the cocoa beans drying machine, please contact LOYAL immediately, we will provide you with high-quality formulations of cocoa beans drying, professional technical process guidance, and a full range of professional market analysis.

Customer Cases For Jam Sandwich Biscuit Production Line For Factory In 2021 | |

| 1 | 1t/h Ce Certificated Industrial Energy Efficient Cocoa Beans Leaf Vegetables Drying Machine Sold In Russia |

| 2 | 1t/h Tunnel Type School Dustless Chalk Microwave Drying Machine For Sale In Puerto Rico |

| 3 | 1t/h Industrial Tunnel Microwave Coffee Cocoa Bean Roasting Dryer Machine For Sale In Bolivia |

| 4 | Senegal 1t/h Industrial Tunnel Micwave Coffee Cocoa Bean Asting Dryer Machine |

| 5 | 1t/h Energy Saving Large Industrial Microwave Food Dehydrator Fish Shrimp Dehydration Microwave Dryer For Sale In Côte d'Ivoire |

| 6 | China 300t/Year Tunnel Microwave Wood Dryer Timber Drying Machine |

Customer Case Of High Quality Industrial Tunnel Microwave Rice Corn Green Cocoa Beans Drying Machine From Phenix Machinery At 2021 | |

| 1 | 1t/h Industrial Tunnel Belt Conveyor Microwave Paper Powder Tea Herbs Leaves Nut Spice Grain Sterilization Dryer Drying Machine In Uzbekistan |

| 2 | 1000kg/h Iguoxin Tunnel Microwave Rice Corn Green Cocoa Beans Drying Sterilization Machine For Sale In Senegal |

| 3 | Mozambique 1t/h Fully Automatic Biscuit Making Machine |

| 4 | Bangladesh 2t/h Fully Industrial Tunnel Microwave Coffee Cocoa Bean Roasting Dryer Machine |

| 5 | 1t/h Thai Industrial Microwave Oven Roasted Hazelnut Sterilization Machine |

| 6 | Uzbekistan 1t/Htunnel Microwave Wheat Rice Powder Flour Drying Sterilization Sterilizer Machine |

| 7 | Usa 1t/h Industrial Tunnel Microwave Rice Corn Green Cocoa Beans Drying Machine |

| 8 | 800kg/h Indian Spice Microwave Garam Masala Sterilizer Machine Black Pepper Drying And Sterilizing Machine |

| 9 | Dealed Customer Have Technology Of Full Automatic New Condition Commercial Fruit Drying Machine Microwave Fruit Dryer Fruit Dehydrator Microwave Food Dehydrators At 2021 |

2021Customer Case Of Pay By T/T For High Quality Industrial Tunnel Microwave Rice Corn Green Cocoa Beans Drying Machine From Phenix Machinery | |

| 1 | 1t/h Industrial Tunnel Belt Conveyor Microwave Paper Powder Tea Herbs Leaves Nut Spice Grain Sterilization Dryer Drying Machine In Afghanistan |

| 2 | 1000kg/h Iguoxin Tunnel Microwave Rice Corn Green Cocoa Beans Drying Sterilization Machine For Sale In Anguilla |

| 3 | Bahrain 1t/h Fully Automatic Biscuit Making Machine |

| 4 | Bangladesh 2t/h Fully Industrial Tunnel Microwave Coffee Cocoa Bean Roasting Dryer Machine |

| 5 | 1t/h Bouvet Islands Industrial Microwave Oven Roasted Hazelnut Sterilization Machine |

| 6 | Central African Republic 1t/Htunnel Microwave Wheat Rice Powder Flour Drying Sterilization Sterilizer Machine |

| 7 | Colombia 1t/h Industrial Tunnel Microwave Rice Corn Green Cocoa Beans Drying Machine |

| 8 | 800kg/h Eritrea Spice Microwave Garam Masala Sterilizer Machine Black Pepper Drying And Sterilizing Machine |

| 9 | Gambia Customer Have Technology Of Full Automatic New Condition Commercial Fruit Drying Machine Microwave Fruit Dryer Fruit Dehydrator Microwave Food Dehydrators At 2021 |