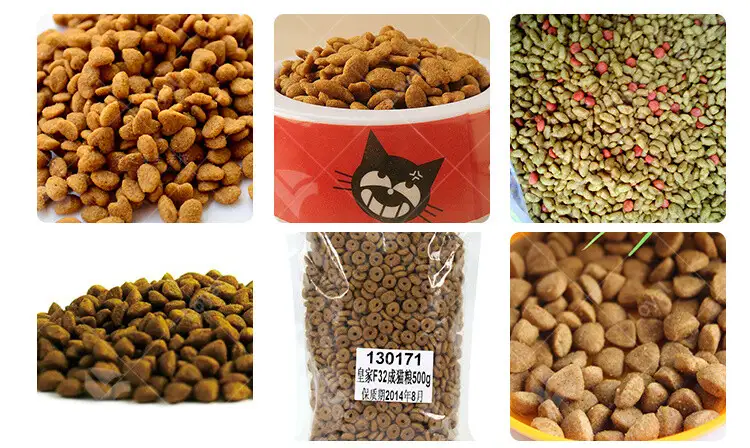

Large Pet Feed Production Line

A large pet feed production line typically involves several stages of processing and packaging to produce high-quality pet food products.Throughout the entire production process, quality control measures are implemented to ensure the safety and quality of the pet food products. This includes regular testing for contaminants, monitoring of production conditions, and adherence to strict quality standards.The pet feed production line can be customized to produce specific types of pet food, such as food for dogs, cats, birds, fish, or other animals.Pet feed production lines are used by pet food manufacturers and can vary in size and complexity depending on the needs of the business. They are an important component of the pet food industry and help ensure that pet owners have access to a wide variety of high-quality pet food products.

The Flowchart Of Large Pet Feed Process Line

1.Mixer --- 2. Scre Conveyor --- 3. Twin Screw Extruder --- 4. Air Conveyor --- 5. Muliti-Layer Oven --- 6. Hoister --- 7. Flavoring Line --- 8. Cooling Conveyor --- 9. Packaging

The Function Of Large Pet Feed Process Line

1.Raw material receiving and storage: The first step is to receive and store the raw materials, which include grains, meat and poultry by-products, vegetable proteins, vitamins and minerals, and other additives.

2.Grinding and mixing: The raw materials are then ground and mixed together in large industrial mixer to create a consistent blend.

3.Conditioning: The mixed materials are then conditioned by adding water and steam, which softens the mixture and makes it easier to extrude.

4.Extrusion: The conditioned mixture is then extruded through a die, which shapes the mixture into small pieces or pellets.

5.Drying: The extruded pellets are then dried in a large oven or dryer to remove any excess moisture.

6.Coating and seasoning: The dried pellets are then coated with fat, oil, or other coatings, and flavored with various seasonings to improve their taste and texture.

7.Cooling and packaging: The finished product is then cooled and packaged in bags, boxes, or other containers for distribution and sale.

The Parameter Of Large Pet Feed Process Line

Model | Installed Powder (kw) | Powder Consumption (kw) | Output (kg/h) | Size(L*W*H) (mm) |

LY65 | 70kw | 45kw | 120-150kg/h | 20000*1200*2200mm |

LY70 | 105kw | 85kw | 200-250kg/h | 22000*1500*2200mm |

LY85 | 160kw | 130kw | 300-500kg/h | 25000*2500*2300mm |

LY95 | 220kw | 154kw | 800-1000kg/h | 28000*2500*3500mm |

The Advantage Of Large Pet Feed Process Line

Increased Production Capacity | A large pet feed process line is designed to handle high-volume production, allowing manufacturers to produce large quantities of pet food in a shorter amount of time. This can help to meet the demands of a growing market and increase profitability. |

Consistent Quality | With a large pet feed process line, manufacturers can achieve consistent quality throughout the production process. This is because the line is designed to ensure that each batch of pet food is made to the same specifications and with the same ingredients. |

Efficient Use Of Resources | Large pet feed process lines are designed to be efficient in their use of resources, such as energy and raw materials. This can help to reduce waste and minimize costs, making the production process more sustainable and environmentally friendly. |

Flexibility | A large pet feed process line can be designed to accommodate a wide range of pet food products, from dry kibble to wet food and everything in between. This can provide manufacturers with greater flexibility in their production capabilities and the ability to meet the needs of a diverse market. |

Improved Safety | Large pet feed process lines are designed to meet strict safety standards and regulations, ensuring that the pet food produced is safe for pets to consume. This can help to protect pets from harmful ingredients and ensure that manufacturers meet their legal obligations. |