Industrial Microwave Tea Drying Technology

Introduction Of Microwave Tea Drying Machine:

Microwave tea drying machines are specialized appliances used to dry tea leaves using microwave radiation. The use of microwave technology to dry tea leaves has proven to be a more efficient and faster way of drying tea leaves compared to conventional methods of drying. Microwave tea drying machines work by converting electrical energy into microwave radiation that is directed to the tea leaves. The radiation causes the water molecules in the tea leaves to vibrate, generating heat that dries the leaves. The machine is designed with a conveyor belt that carries the tea leaves through the microwave chamber, exposing them to the radiation. The drying time and temperature can be adjusted depending on the type and quality of tea leaves being dried. Microwave tea drying machines are favored for their ability to dry tea leaves uniformly, without the risk of over or under-drying. The technology also helps to retain the freshness and flavor of the tea leaves while reducing their moisture content. The use of microwave tea drying machines in the tea processing industry has resulted in faster processing times, improved tea quality, and increased production efficiency.

Parameter Of Microwave Tea Drying Machine:

| Equipment Model | LY-100 Industrial Microwave Drying Machine For Tea |

| Rated Input Apparent Power | Customization |

| Height Of Conveyor | 600-1000mm |

| Inlet And Outlet Height | 40-100mm |

| Width Of Conveyor Belt | 750±100mm(Custom-Made) |

| Microwave Leakage Standard | ISO≤5mw/Cm² |

| Operating Frequency | 2450±50Hmz |

| Transmission Speed | 0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Tea Drying Machine:

1.High efficiency: Microwave tea drying machines use microwave radiation to dry tea leaves, which is more efficient than conventional drying methods. The machines can reduce drying time by up to 50% while maintaining the quality of the tea leaves.

2. Precise temperature control: The machines have a temperature control system that enables users to set the required temperature for drying tea leaves. The system ensures that tea leaves are dried at the right temperature, preventing over or under-drying, which can affect the quality of the tea.

3. Uniform drying: The microwave radiation is evenly distributed across the tea leaves, providing uniform drying. The machines have a conveyor belt that moves the tea leaves through the chamber to ensure that all the tea leaves are exposed to the microwave radiation.

4. Retention of tea flavor and aroma: Microwave tea drying machines dry tea leaves quickly, which reduces the chance of the tea losing its flavor and aroma. The machines also prevent oxidation of tea leaves, which can result in a loss of flavor.

5. Easy operation: Microwave tea drying machines are easy to operate, and users can adjust the drying time and temperature according to the type of tea being processed. The machines require minimal maintenance, making them cost-efficient to operate in the long run.

Overall, microwave tea drying machines are an essential part of the tea processing industry as they provide a fast, efficient, and cost-effective way of drying tea leaves while maintaining their quality and flavor.

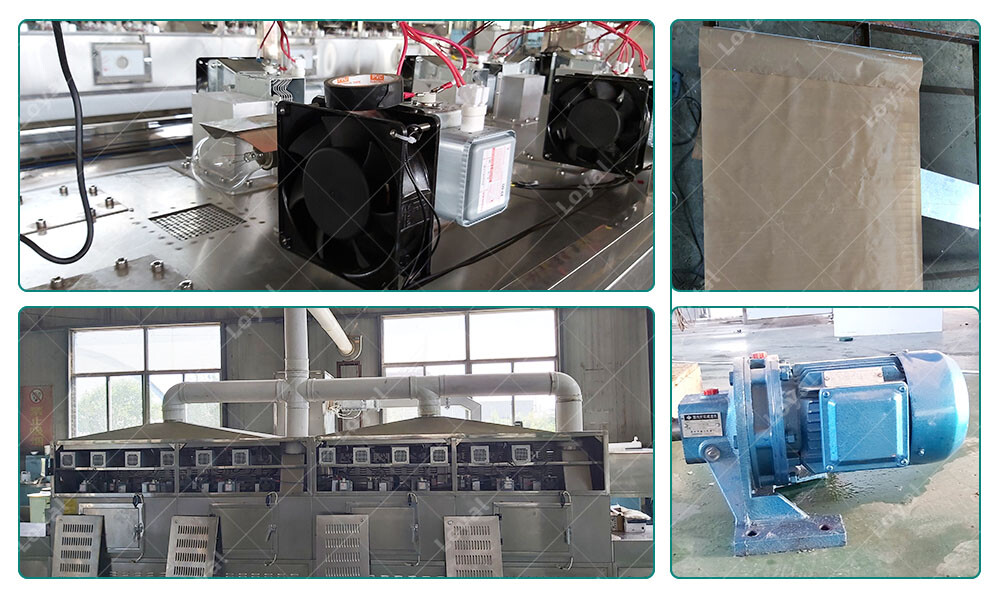

Details Displays Of Microwave Tea Drying Machine:

Applications Of Microwave Tea Drying Machine:

1.Large-scale tea production: Microwave tea drying machines are used in large-scale tea production facilities to dry tea leaves quickly and efficiently. The machines can handle high volumes of tea leaves, making them ideal for large-scale tea production.

2. Small-scale tea production: Microwave tea drying machines are also used in small-scale tea production facilities or by individual tea producers. The machines are compact and easy to operate, making them ideal for small-scale operations.

3. Specialty tea production: Microwave tea drying machines are used to produce specialty teas, such as green tea, white tea. These teas require specific drying conditions to maintain their unique flavor and aroma, and microwave tea drying machines provide precise temperature control to achieve these conditions.

4. Research and development: Microwave tea drying machines are used in research and development labs to study the effects of different drying conditions on tea leaves. The machines allow researchers to control the drying time and temperature, providing accurate data for their experiments.

5. Food processing: Microwave tea drying machines are also used in other food processing applications, such as drying herbs, fruits, and vegetables. The machines can reduce drying time and maintain the quality and flavor of the food products.

Overall, microwave tea drying machines are versatile tools used in several applications in the tea processing industry and other food processing industries.

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Energy Efficient: The equipment uses less energy compared to traditional drying and sterilization methods, reducing energy costs and contributing to a more sustainable food manufacturing process.

2. Improved Product Quality: Microwave drying preserves the natural flavors, colors, and nutritional benefits of the food, resulting in a higher quality end product.

3. Uniform Drying and Sterilization: Microwave technology allows for even and consistent drying and sterilization, ensuring that all parts of the food are treated equally.

4. Reduced Microbial Load: Microwave sterilization can effectively eliminate harmful bacteria and pathogens from the surface of the food, ensuring that it is safe for consumption.

5. Increased Shelf Life: The reduction in moisture and microbial load can result in an extended shelf life of the food, reducing waste and enhancing food safety.

6. Versatility: Microwave drying and sterilization equipment can be used for a wide range of food products, including fruits, vegetables, meats, and grains, making it a more versatile tool in the food processing industry.

Overall, the benefits of microwave drying and sterilization equipment make it a valuable and cost-effective investment for food manufacturing companies looking to improve efficiency, quality, and safety.