Industrial Microwave Prawn Drying Technology

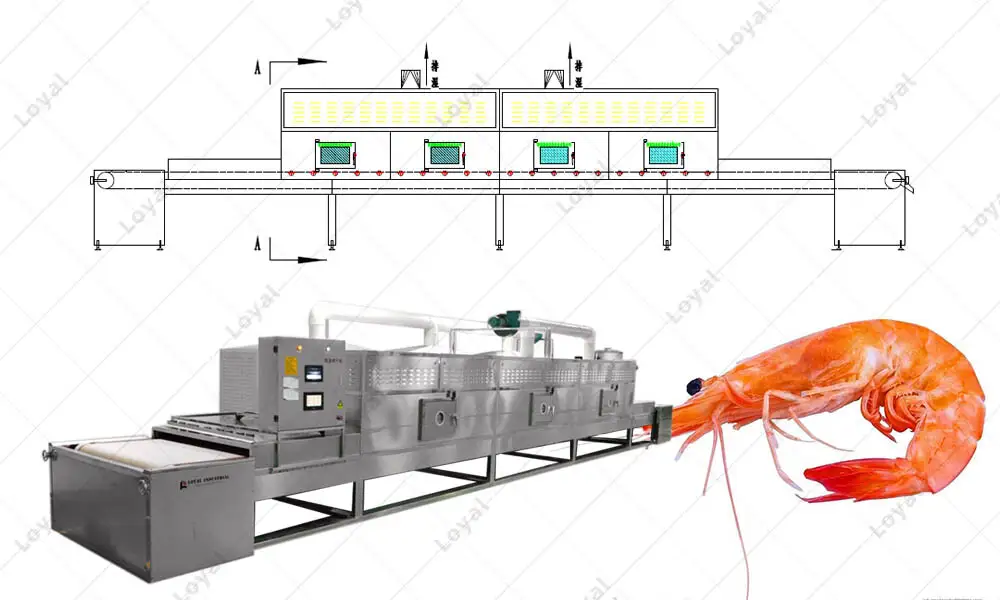

Introduction Of Microwave Prawn Drying Machine:

A microwave prawn drying machine is a device that uses microwave radiation to dry prawns or other seafood quickly and efficiently. This type of machine is commonly used in the seafood processing industry to dry large quantities of prawns at once.Compared to traditional drying methods, such as air drying or sun drying, microwave drying is much faster and more energy-efficient. It also has the advantage of preserving the quality and nutritional value of the prawns, as the high heat and short drying time prevent overcooking or loss of flavor.

Overall, microwave prawn drying machines are an innovative and efficient solution for the seafood industry, providing a quick and reliable way to process large quantities of prawns while maintaining their quality and freshness.

Feature Of Microwave Prawn Drying Machine:

1.High drying efficiency: Microwave drying technology allows for quick and efficient drying of prawns, reducing the drying time and energy consumption compared to traditional drying methods.

2.Precise temperature control: The machine is equipped with temperature sensors and controllers that allow for precise temperature control during the drying process, ensuring that the prawns are dried evenly and without overcooking.

3.Large capacity: Microwave prawn drying machines are available in various sizes and capacities, ranging from small tabletop models to large industrial-scale machines that can dry large quantities of prawns at once.

4.Easy operation: Most microwave prawn drying machines are designed with user-friendly interfaces and controls, making them easy to operate and adjust.

5.Safety features: The machine is designed with safety features such as automatic shut-off systems to prevent overheating and other potential hazards.

6.Low maintenance: Microwave prawn drying machines require minimal maintenance and are designed for easy cleaning and upkeep.

Parameter Of Microwave Prawn Drying Machine:

1. Equipment Model | LY-60HM (Continuous) |

2. Equipment Power | 90Kva |

3. Microwave Power | 60Kw (Adjustable) |

4. Equipment Size (Length*Width*Height) | 10520*1802*1750mm (Size Can Be Customized) |

5. Thawing Material Temperature | -2 - Below 0°C |

6. Equipment Material | The Whole Machine Is Made Of 304 Stainless Steel |

7. Equipment Capacity | 800~1000 Kg/Hour |

8.Equipment Color | Silver |

Details Display Of Microwave Prawn Drying Machine;

Applications Of Microwave Prawn Drying Machine:

1 | Commercial seafood processing | Microwave prawn drying machines are used in seafood processing plants to dry large quantities of prawns quickly and efficiently. |

2 | Food preservation | Dried prawns have a longer shelf life than fresh prawns and are less susceptible to spoilage. Microwave prawn drying machines are therefore used to preserve prawns for longer periods. |

3 | Food preparation | Dried prawns are a popular ingredient in many cuisines and can be used in a variety of dishes, including soups, stews, and stir-fries. |

4 | Research and development | Microwave prawn drying machines are also used in research and development laboratories to study the effects of microwave drying on prawns and other seafood. |

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Adopt Food Grade Stainless Steel, Nice Appearance, Easy To Clean.

2.Microwave Can Penetrate Through The Materials So That The Inside And Outside Are Heated At The Same Time, Short Processing Time,Evenly Drying And Thorough Terilization. No Extra Heat Loss, High Heat Efficiency, Saving Energy.

3.Thermal Effect And Non-Thermal Effect Work Together, Achieving Ideal Sterilization Effect At Low Temperature And Short Time, The Vegetable Can Keep Their Nutrition Components To The Maximum.

4.Adopt Non-Contact Infrared Temperature Measurement Technology, High Precision, Automatic Control.

5.Frequency Adjustable Conveyor Speed, Step-less Adjustable Microwave Power, Instant Heating And Stop, No Thermal Inertia,Convenient Operation.

6.Adopt Human-Machine Interface Operation And PLC Touch Screen Control, Realizing Automatic Control.

7.Microwave Leakages ≤1mw/ Cm2, No Heat Radiation, Improving The Work Environment.