Industrial Microwave Gelatine Drying Technology

Introduction Of Microwave Gelatine Drying Machine:

Microwave gelatine drying machine is an advanced and efficient equipment that uses microwave technology for drying and dehydrating gelatine. The machine is designed to remove moisture from the gelatine in a short time, without damaging the quality, taste, and nutritional value of the product.Overall, the microwave gelatine drying machine is a valuable tool for the gelatine production industry, providing a fast, efficient, and high-quality drying process that increases productivity and profitability.

Parameter Of Microwave Gelatine Drying Machine:

| Equipment Model | LY-100 Industrial Microwave Drying Machine For Gelatine |

| Rated Input Apparent Power | Customization |

| Height Of Conveyor | 600-1000mm |

| Inlet And Outlet Height | 40-100mm |

| Width Of Conveyor Belt | 750±100mm(Custom-Made) |

| Microwave Leakage Standard | ISO≤5mw/Cm² |

| Operating Frequency | 2450±50Hmz |

| Transmission Speed | 0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Gelatine Drying Machine:

1. Advanced Microwave Technology: The machine uses advanced microwave technology that generates high-frequency electromagnetic waves.

2. Even Heat Distribution: The conveyor belt and rotating plate ensure that the gelatine is evenly exposed to heat.

3. Precise Control: The drying process can be controlled precisely by adjusting the microwave power, belt speed, and temperature.

4. Low Temperature Drying: Microwave drying does not require high temperatures, reducing the risk of gelatine damage .

5. Easy to Operate: The machine is easy to operate and maintain, with a user-friendly interface and simple controls.

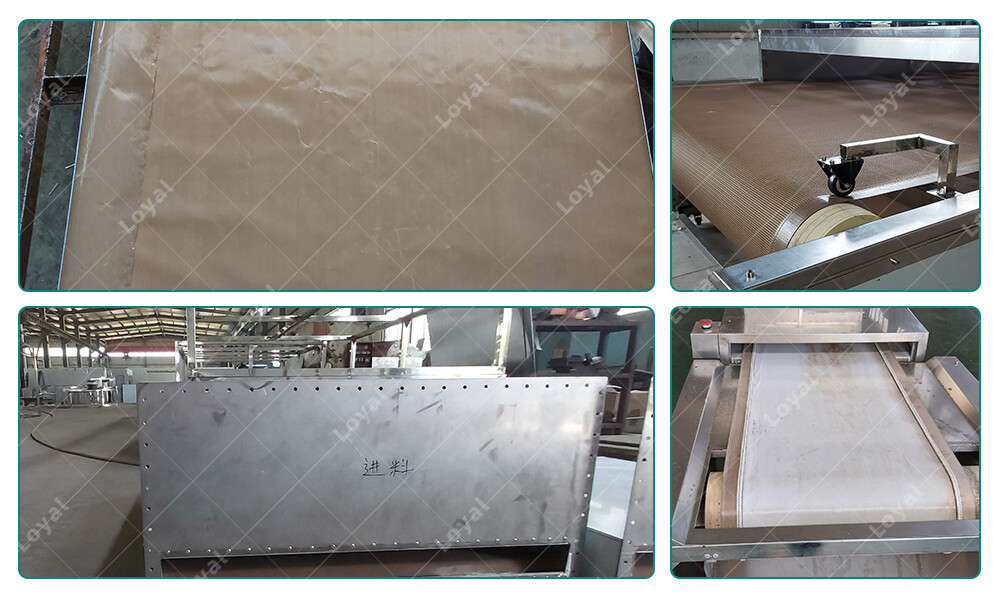

Details Display Of Microwave Gelatine Drying Machine:

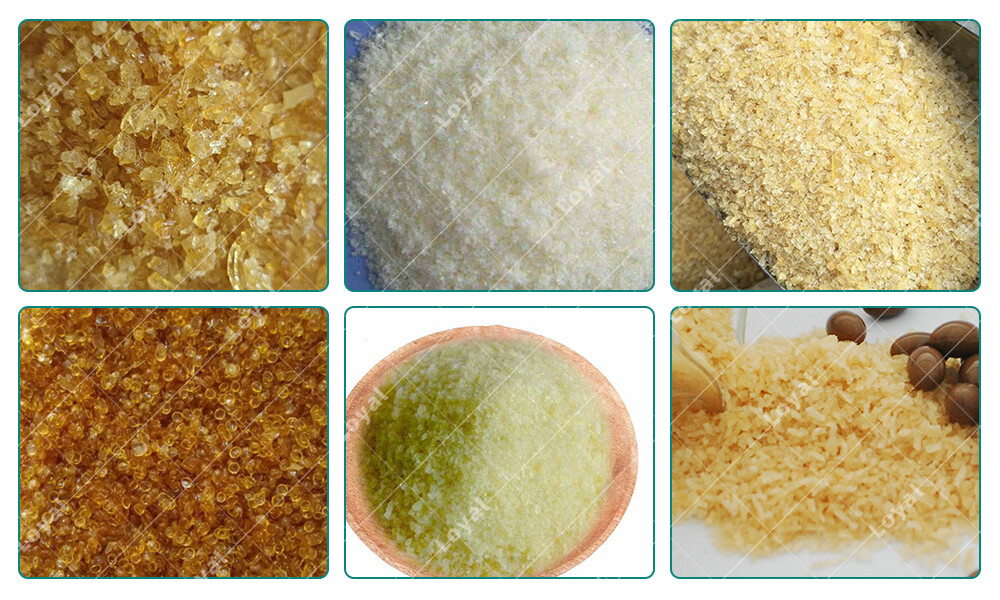

Applications Of Microwave Gelatine Drying Machine:

| 1 | Gelatine Production | Microwave drying is an essential step in gelatine production, where it is used to remove excess moisture from gelatine sheets, granules or powder. |

| 2 | Meat Processing | Microwave drying is used to remove excess moisture from meat or meat products, improving the quality, texture, and shelf life of the product. |

| 3 | Snack Foods | Microwave drying is commonly used in the production of snack foods like potato chips, popcorn, and dried fruits to remove moisture, improving their crunchiness and shelf life. |

| 4 | Pharmaceutical Industry | Microwave drying is used in the production of pharmaceuticals, particularly in the drying of some drug formulations, herbal extracts, and pharmaceutical intermediates. |

| 5 | Chemical Industry | Microwave drying is used to dry certain chemicals, including catalysts, dyes, and pigments, among others. |

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Adopt Food Grade Stainless Steel, Nice Appearance, Easy To Clean.

2.Microwave Can Penetrate Through The Materials So That The Inside And Outside Are Heated At The Same Time, Short Processing Time,Evenly Drying And Thorough Terilization. No Extra Heat Loss, High Heat Efficiency, Saving Energy.

3.Thermal Effect And Non-Thermal Effect Work Together, Achieving Ideal Sterilization Effect At Low Temperature And Short Time, The Vegetable Can Keep Their Nutrition Components To The Maximum.

4.Adopt Non-Contact Infrared Temperature Measurement Technology, High Precision, Automatic Control.

5.Frequency Adjustable Conveyor Speed, Step-less Adjustable Microwave Power, Instant Heating And Stop, No Thermal Inertia,Convenient Operation.