Industrial Microwave Fresh Meat Defrosting Technology

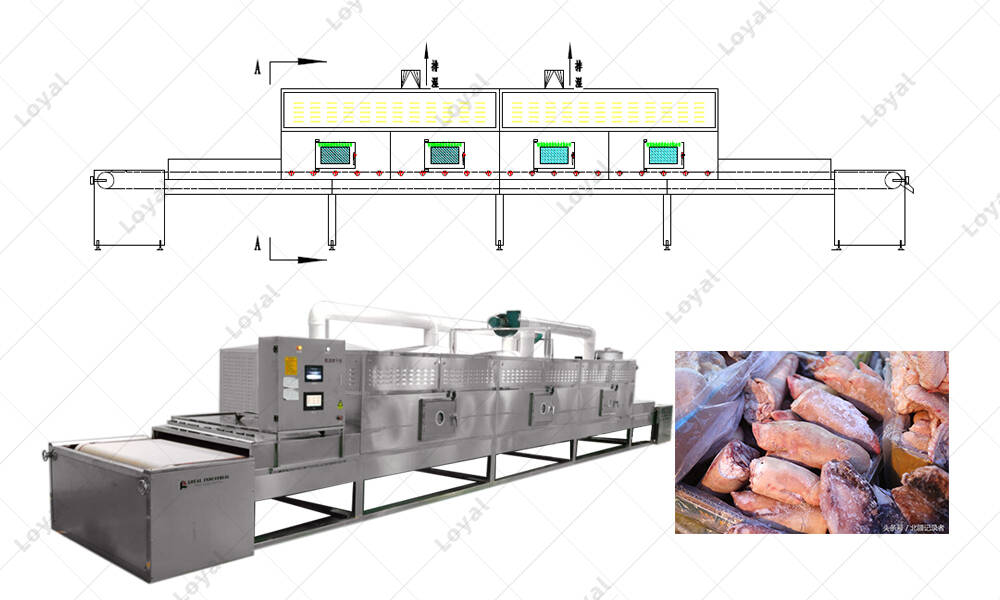

Introduction Of Microwaveof Fresh Meat Defrosting Machine:

An industrial microwave fresh meat defrosting machine is a larger, more powerful version of the microwave defrosting machine designed for use in industrial settings such as food processing plants, meat packing facilities, and large commercial kitchens. It uses the same principle of generating heat with microwaves to quickly and efficiently defrost large quantities of frozen meat.

Industrial microwave fresh meat defrosting machines can handle large volumes of frozen meat, reducing the amount of time and labor required for manual defrosting. They are also designed to meet strict food safety standards and regulations, ensuring that the defrosted meat remains safe for consumption.

Parameter Of Microwave Fresh Meat Defrosting Machine:

| Equipment Model | LY-100 Industrial Microwave Defrost Machine For Fresh Meat |

| Rated Input Apparent Power | Customization |

| Height Of Conveyor | 600-1000mm |

| Inlet And Outlet Height | 40-100mm |

| Width Of Conveyor Belt | 750±100mm(Custom-Made) |

| Microwave Leakage Standard | ISO≤5mw/Cm² |

| Operating Frequency | 2450±50Hmz |

| Transmission Speed | 0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Fresh Meat Defrosting Machine:

1.Large Capacity: Industrial microwave fresh meat defrosting machines are designed to handle large volumes of frozen meat, allowing for fast and efficient defrosting of large quantities.

2.Adjustable Power Settings: The machines typically have adjustable power settings to allow for customization .

3.Conveyor Belt: The machine often includes a conveyor belt system to move the meat through the machine.

4.Temperature Control: The machine may have temperature control features that allow for monitoring and control of the temperature of the defrosting process.

5.Safety Features: Industrial microwave fresh meat defrosting machines are designed with safety features .

Details Display Of Microwav Fresh Meat Defrosting Machine:

Applications Of Microwave Fresh Meat Defrosting Machine:

| 1 | Food Processing Plants | The machines are used in food processing plants to defrost large quantities of frozen meat quickly and efficiently. |

| 2 | Meat Packing Facilities | Meat packing facilities use microwave defrosting machines to defrost frozen meat before processing and packaging. |

| 3 | Commercial Kitchens | Restaurants and other commercial kitchens use microwave defrosting machines to quickly defrost meat for use in meals. |

| 4 | Grocery Stores | Some grocery stores use microwave defrosting machines to defrost frozen meat before selling it to customers. |

| 5 | Home Kitchens | Microwave defrosting machines are also available for home use, allowing for convenient and quick defrosting of frozen meat. |

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Adopt Food Grade Stainless Steel, Nice Appearance, Easy To Clean.

2.Microwave Can Penetrate Through The Materials So That The Inside And Outside Are Heated At The Same Time, Short Processing Time,Evenly Drying And Thorough Terilization. No Extra Heat Loss, High Heat Efficiency, Saving Energy.

3.Thermal Effect And Non-Thermal Effect Work Together, Achieving Ideal Sterilization Effect At Low Temperature And Short Time, The Vegetable Can Keep Their Nutrition Components To The Maximum.

4.Adopt Non-Contact Infrared Temperature Measurement Technology, High Precision, Automatic Control.

5.Frequency Adjustable Conveyor Speed, Step-less Adjustable Microwave Power, Instant Heating And Stop, No Thermal Inertia,Convenient Operation.