Industrial Microwave Bread crumbs Drying Technology

Introduction Of Microwave Bread Crumbs Drying Machine:

Microwave bread crumbs drying machine is a type of equipment used to dry and dehydrate bread crumbs using microwave technology. Microwave bread crumbs drying machine is specifically designed to lower the moisture content of bread crumbs, making them last longer and increasing their shelf life. The microwave drying method allows for fast and efficient drying, which is crucial in maintaining the quality and freshness of the bread crumbs.The machine is made up of a conveyor belt and a microwave chamber. Bread crumbs are fed onto the conveyor belt, which moves them through the microwave chamber at a controlled speed. The microwave chamber is equipped with microwave generators that emit microwave radiation, which heats the bread crumbs and removes the moisture content.The microwave bread crumbs drying machine offers several advantages over traditional drying methods. Firstly, it is a fast and efficient drying method, reducing the drying time from hours to just minutes. Secondly, it is a gentle and controlled drying process, reducing the risk of over-drying or burning the bread crumbs. Lastly, it is an environmentally friendly method, as it requires less energy and emits less greenhouse gases than traditional drying methods.Overall, the microwave bread crumbs drying machine is an essential piece of equipment for bread crumb manufacturers who want to produce high-quality, long-lasting products efficiently and sustainably.

Parameter Of Microwave Bread Crumbs Drying Machine:

| Equipment Model | LY-100 Industrial Microwave Drying Machine For Bread Crumbs |

| Rated Input Apparent Power | Customization |

| Height Of Conveyor | 600-1000mm |

| Inlet And Outlet Height | 40-100mm |

| Width Of Conveyor Belt | 750±100mm(Custom-Made) |

| Microwave Leakage Standard | ISO≤5mw/Cm² |

| Operating Frequency | 2450±50Hmz |

| Transmission Speed | 0~10m/Min(Adjustable Frequency) |

Feature Of Microwave Bread Crumbs Drying Machine:

1.A microwave bread crumbs drying machine uses microwave radiation to reduce the moisture content in bread crumbs quickly and efficiently. This method of drying is much faster than conventional drying methods.

2.Uniform Drying: Microwave radiation penetrates equally to every part of the bread crumbs, resulting in uniform drying. This reduces the risk of over-drying or burning the bread crumbs, thereby maintaining their quality and taste.

3. Easy to Operate: The machine is simple to operate, with a user-friendly interface. Operators can easily set the drying temperature, power level, and time.

4. Low Energy Consumption: Microwave bread crumbs drying machines are energy-efficient and consume less power compared to conventional dryers thanks to the rapid and efficient drying process. Energy can be saved by using a multi-step drying method that further reduces the moisture content.

5. Easy Maintenance: The machine is easy to maintain as it has simple components that only need regular cleaning, inspection, and replacement of parts, if required.

6. Compact Size: The microwave bread crumbs drying machine is compact and does not require large space, making it suitable for small and medium-sized production environments.

7. High Capacity: The machine can handle substantial quantities of bread crumbs in one batch, making it ideal for industrial scale production.

Overall, the microwave bread crumbs drying machine offers a fast, efficient, and uniform method of drying bread crumbs without compromising their quality and taste.

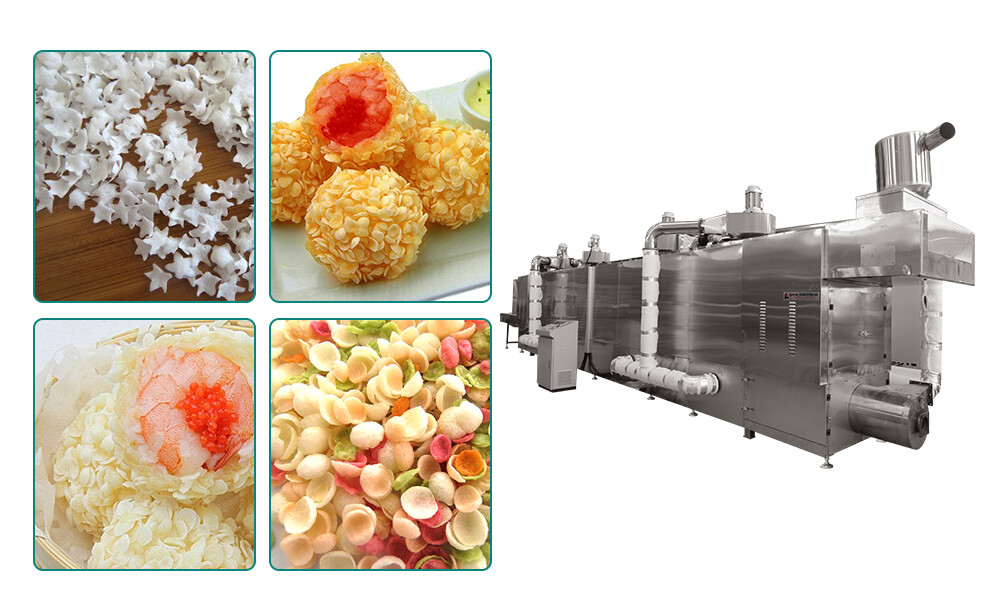

Details Displays Of Microwave Bread Crumbs Drying Machine:

Applications Of Microwave Bread Crumbs Drying Machine:

1.Bakery Industry: The bread crumbs drying machine is used to dry bread crumbs that are left over after slicing bread. The dried bread crumbs can be reused in the bakery or sold as standalone products.

2. Catering Industry: The machine is used in catering to dry bread products such as garlic bread, breaded chicken or fish, onion rings, and other coated snacks. Dried bread crumbs make the coating crispy, oil-free, and longer shelf life.

3. Ready-to-Eat Food Industry: In the ready-to-eat food industry, the microwave bread crumbs drying machine is used to dry the crumbs used for toppings on pizzas, lasagnas, and other food products. Dried bread crumbs add taste and texture to the dishes.

4. Snacks Industry: The bread crumbs drying machine is also used to dry the crumbs that are used for making snacks, such as crackers, pretzels, and chips.

5. Baby Food Industry: Dried bread crumbs can be used in the baby food industry as it helps to make the food more solid and easier to handle while reducing the amount of moisture.

Overall, the microwave bread crumbs drying machine is used to save wastage and money, improve the quality of food products, and maintain their original taste and texture.

Advantages Of Loyal Microwave Drying And Sterilization Equipment:

1.Energy Efficient: The equipment uses less energy compared to traditional drying and sterilization methods, reducing energy costs and contributing to a more sustainable food manufacturing process.

2. Improved Product Quality: Microwave drying preserves the natural flavors, colors, and nutritional benefits of the food, resulting in a higher quality end product.

3. Uniform Drying and Sterilization: Microwave technology allows for even and consistent drying and sterilization, ensuring that all parts of the food are treated equally.

4. Reduced Microbial Load: Microwave sterilization can effectively eliminate harmful bacteria and pathogens from the surface of the food, ensuring that it is safe for consumption.

5. Increased Shelf Life: The reduction in moisture and microbial load can result in an extended shelf life of the food, reducing waste and enhancing food safety.

6. Versatility: Microwave drying and sterilization equipment can be used for a wide range of food products, including fruits, vegetables, meats, and grains, making it a more versatile tool in the food processing industry.

Overall, the benefits of microwave drying and sterilization equipment make it a valuable and cost-effective investment for food manufacturing companies looking to improve efficiency, quality, and safety.