How To Choose The Bestnutrition bar production lines: 2025 Buyer’s Guide

In the early morning, the hurried footsteps are always looking for a companion that can both soothe the stomach and ignite energy. The moment the package is torn open, the aroma of oats and honey spreads gently, like the warmth of the sun shining over the wheat fields. This palm-sized nutrition bar, wrapped with the crispness of nuts, the sourness of berries, and the earthy texture of grains, is just the right gentle supply in urban life.

It was born from the obsession with "just right" - not too sweet, but enough to awaken the tired taste buds; no need for tedious preparation, but can provide solid energy. The protein bars quietly prepared in the gym bag, the nut bars in the office drawer for emergency, or the energy blocks in the pocket when hiking... These small cubes hide the simple expectations of modern people for health: to find the delicate balance between efficiency and deliciousness.

When the gears of the machine meet the gifts of nature, when the traditional formula is integrated with modern technology, the nutrition bar is no longer just a substitute in a hurry. It is the golden ratio that bakers repeatedly adjust, it is the meticulous temperature control on the production line, and it is also a sweet and safe station where every busy soul can stop for a short while.

Introduction

The global demand for healthy, on-the-go snacks has surged, with nutrition bars leading the market as a convenient source of protein, fiber, and essential nutrients. According to Dr. Emily Carter, a food technology expert at the International Food Science Alliance, "Automation is no longer optional in snack manufacturing—it’s the cornerstone of meeting scale, safety, and consistency demands."

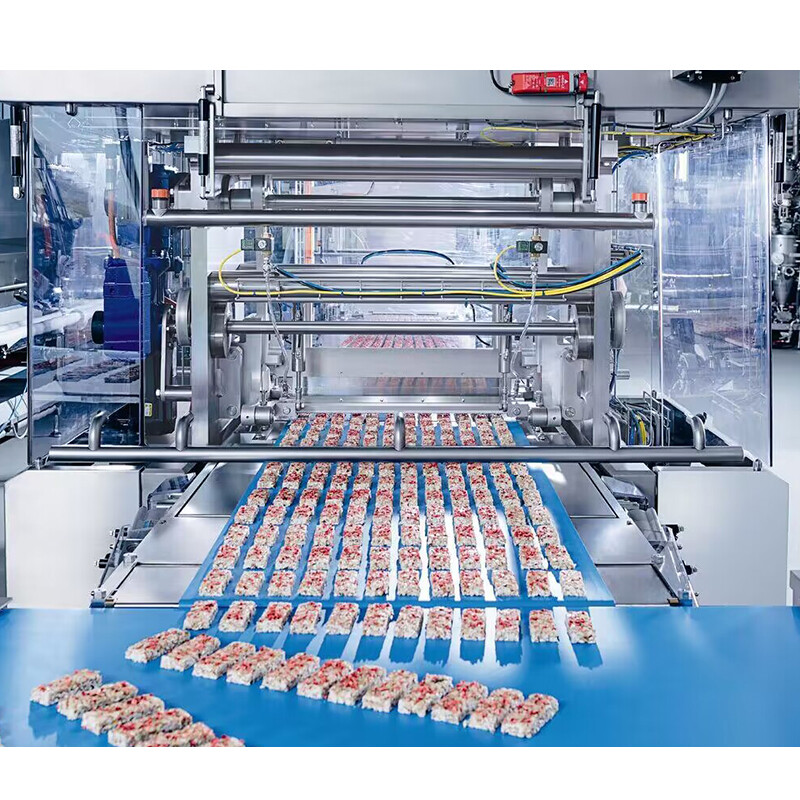

Fully automatic nutrition bar production lines represent the pinnacle of modern food engineering. These integrated systems handle everything from ingredient mixing to packaging with minimal human intervention.

Key Components of a Nutrition Bar Production Line

Ingredient Mixing and Preparation Systems

High-shear mixers blend ingredients (oats, nuts, syrups) into homogeneous doughs.

Ensure consistent flavor and texture.

Forming and Shaping Units

Extrusion or molding technology creates uniform bar sizes (e.g., 50g or 100g units).

Adjustable molds accommodate protein bars, energy bars, or granola varieties.

Cooling: Stabilize bar texture (chewy or crunchy).

Cooling function prevents stickiness before packaging.

Cutting and Packaging Modules

cutters slice bars.

Flow-wrap or pouch packaging machines seal products for extended shelf life.

Advantages of Full Automation

Higher Output | Higher Output: Compared with manual |

Hygiene | Closed systems reduce contamination risks—critical for allergen-free production. |

Consistency | Ensures each bar meets label claims. |

Waste Reduction | Exact ingredient dosing cuts raw material waste. |

Applications in the Food Industry

Large-Scale Production: Ideal for brands targeting supermarkets or fitness chains.

Customization: Swap molds and recipes to shift between keto, vegan, or gluten-free bars.

Future Trends in Nutrition Bar Equipment

Clean-Label Focus: Equipment designed for minimal additives (e.g., no binders or preservatives).

Scalability: Compact modular designs allow small producers to adopt automation.

The shift toward fully automatic nutrition bar production lines is reshaping the snack industry. By combining speed, precision, and adaptability, these systems empower manufacturers to meet evolving consumer needs—from allergen-free options to sustainable practices.

As Dr. Carter notes, "The next decade will see automation become the default, not the exception, in functional food manufacturing." Investing in advanced nutrition bar manufacturing machines today positions brands for growth in tomorrow’s competitive market.

Nutrition bar production line flow chart

Sugar boiled pot--- Mixer--- Cereals bar cutting machine--- Packaging machine

Nutrition bar equipment is not limited to the ones mentioned above, and other equipment can be added as needed.

For example, if you want to make a rounded arched nutrition bar, you need a mold forming machine. If the raw material has high viscosity, you need to add a refrigerator and a strip cutter. If you want coating and latte art, you need to add a coating machine and a latte art machine.

The function of nutrition bar production line

1.Sugar boiled pot: can melt sugar, stir, and boil sugar together

2.Mixer: mixing raw materials. With heat preservation effect, the inner wall is sprayed with Teflon, and the stirring shaft and stirring claws are sprayed with Teflon

3.Cereals bar cutting machine: used for leveling, cooling, cutting and forming of products.

4.Packaging machine: finally, the dried bar is packaged in a suitable container and labeled for distribution. Packaging is an important step to ensure that the product remains fresh and free from contamination during transportation and storage.

Layout for the nutrition bar production line

Our machines can be flexibly arranged according to the size and dimensions of the factory. We can also customize the size of the machine according to the data you provide.

Sample of nutrition bar production line

Other substances and nutrients can be added as needed, such as chocolate, nuts, fruits, iron, calcium, vitamin D, etc.

If you are interested, I will recommend a company to you, please continue reading.

Recommended Company

Shandong Loyal Industrial Co.,Ltd. Is a Manufacturer Of Snacks Extruder Machine , Industrial Microwave Oven , Corn Flakes Production Line , And a Standing Director Of China Food And Drying Equipment Industry Association.

The Self-developed Twin-screw Extruder And Single-screw Equipment of Shandong Loyal Machinery Have Been Used In Production: Puffed Snack Food, Breakfast Cereal Corn Flakes, Fried Pasta, Bread Crumbs, Fruit Chips, Baby Food, Textured Soy Protein (tsp) Food, Fish Feed And Pet Food. a Variety of Snack Production Line Supporting Products.at The Same Time, The Batching, Drying, Flaking, Baking, Frying And Spraying Equipment Matching The Twin-screw Extrusion System Have All Achieved Independent Design And Production.

Our Extrusion System Is Widely Used In: Puffed Snack Foods, Breakfast Cereals, Vegetable Protein Meat Products, Soy Based Nutrition Bars, Reconstituted Rice, Grain Nutrition Powder, Modified Starch, Starch-based Sticky Music Children's Educational Toys, Degradable Starch-based Packaging Filling Materials, Bread Crumbs And Other Food Additives, Pet Food, Aquatic Feed, Biology And Chemical Industries.

Customer-specific Food Processing Plant Project Solutions

As one of the leading manufacturers of food processing equipment, we are always searching for new solutions that benefit our snack food customers. Our experienced frying engineers always find the optimal solution for your industrial batch and continuous frying system line application. That's why we also develop, design and produce custom fried snack production line.

Close collaboration with our customer is important to us even in the early development phase. No matter what the special requirements of instant noodles production line, snack food extruder machine, pasta production line application, we can develop a custom made food processing equipment to match your needs.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

Loyal Food Production Line meet the needs of customers to obtain snack food that meet the needs.

In ovens or drying units, electric or gas can be used as heating sources.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

About packaging and after-sales service

Packing:Plastic Film Suitable For Ocean Carriage

Technical Support: The customer can inform machine related problems to us via telephone, email or fax. All information will be recorded and will be reported to the After-sale Service team. Meanwhile, the sales person will be tracking the case until problem solved.

Service Team:We have a professional After-sale Service team including10 professional engineers with at least 6 years working experience. They can handle technical consultation about manufacturing process, maintenance, fault diagnosis and troubleshooting, etc.

After-sale Service available :1.Check & test before delivery 2.Instruction for installation 3.On site commissioning 4.Repair & maintenance

After the receipt the advanced payment, we will provide allocation chart at the buyer’s request. When effect the shipment, we’ll provide operation manual, etc. in English.

The Future of Fully Automatic Nutrition Bar Equipment

The nutrition bar market has exploded, projected to reach $7.5 billion by 2027 (Grand View Research). "Consumers now view bars not just as snacks but as functional fuel," observes Mark Wilson, Senior Analyst at FoodTrends International. This shift has driven manufacturers toward automated nutrition bar equipment that can keep pace with demand while maintaining nutritional integrity.000

The nutrition bar production industry is experiencing rapid growth, driven by increased consumer demand for healthy, on-the-go snack options. As technology continues to evolve, so too does the potential for automation in the production of nutrition bars. Fully automatic systems like nutrition bar production line, nutrition bar manufacturing machine, and nutrition bar equipment are at the forefront of this transformation. As the industry moves forward, several emerging trends and technological innovations are expected to shape the future of nutrition bar production.

1. Emerging Trends in Snack Production Technology

The snack industry is becoming increasingly focused on health-conscious, functional foods. As consumers continue to demand snacks that offer not only great taste but also specific nutritional benefits, manufacturers are responding by incorporating innovative ingredients and packaging technologies into their products. Fully automatic nutrition bar equipment will play a central role in enabling manufacturers to meet these evolving demands.

One emerging trend is the rise of personalized nutrition. Consumers are now looking for snacks that cater to their unique dietary needs, such as keto, vegan, or gluten-free options. This trend is driving the need for nutrition bar production line that can quickly adapt to different formulations and ingredients, allowing manufacturers to produce a wide variety of nutrition bars on the same production line.

Another trend is the increasing use of plant-based ingredients. As plant-based diets become more popular, nutrition bar manufacturing machines are being adapted to handle a wider range of ingredients such as pea protein, oats, and quinoa. The ability to incorporate these ingredients seamlessly into the production process will be a key factor in the continued success of fully automatic nutrition bar equipment.

2. Potential Improvements in Automation and Sustainability

As the push for greater sustainability in food production continues to grow, manufacturers are focusing on improving the energy efficiency and environmental impact of nutrition bar equipment. The next generation of fully automatic equipment is expected to be even more energy-efficient, helping companies lower their carbon footprint while maintaining high production levels.

Additionally, innovations in waste reduction are expected to become a significant focus for future production lines. Improved precision in ingredient handling and better process control will lead to less waste, both in terms of raw materials and finished products. Enhanced monitoring systems will allow manufacturers to track the entire production process, identifying areas where waste can be minimized and efficiency improved.

3. The Role of Automation in Enhancing Consumer Experiences and Product Accessibility

Automation is not only transforming the production process but is also helping companies enhance the consumer experience. By enabling faster production and reducing costs, manufacturers can pass these savings onto consumers, making nutritious snacks more affordable and accessible. The ability to scale production quickly and consistently ensures that high-quality nutrition bars remain readily available in stores, allowing consumers to access healthier snack options at competitive prices.

Additionally, automation enables manufacturers to introduce new packaging innovations that improve convenience for consumers. For example, smart packaging that tracks product freshness or offers personalized nutrition information is becoming more common. This is particularly important in an era where consumers are increasingly looking for transparency in the products they buy.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/