How To Choose The Bestmaize puff making machine: 2025Buyer’s Guide

Brief History of Maize Puffing as a Snack-Making Process

The journey of transforming humble corn kernels into the crispy, airy delight we know as maize puffs has a rich and fascinating history rooted in innovation and culinary creativity. While the exact origins of maize puffing are difficult to pinpoint, the process has evolved significantly over centuries, driven by advancements in food technology and changing consumer preferences.

1.Early Beginnings: Traditional Methods and Cultural Significance

Maize, or corn, has been a dietary staple for centuries, particularly in regions like Central and South America, where it was first domesticated. Indigenous communities developed various methods to process corn, including grinding it into flour or boiling it into porridge. However, the concept of puffing corn likely emerged as a way to preserve and enhance its texture and flavor. Early techniques may have involved heating corn kernels over open flames or in clay pots, causing the moisture inside to expand rapidly and create a puffed structure. This method not only made corn more palatable but also extended its shelf life, making it a valuable food source during lean seasons.

2.Industrial Revolution and Mechanization

The industrial revolution in the 18th and 19th centuries marked a turning point in food processing, including maize puffing. With the advent of steam engines and later, electricity, manufacturers began to mechanize the process of puffing corn. Early machines, often rudimentary in design, used steam pressure or direct heat to expand corn kernels. These innovations laid the foundation for modern maize puff making machines, which would eventually revolutionize the snack food industry.

3.The Rise of Commercial Maize Puff Production

The 20th century saw the commercialization of maize puffing on a massive scale. Companies like General Mills and Kellogg’s played pivotal roles in popularizing puffed corn snacks, introducing them to global markets under brand names like Corn Pops and Puffcorn. These snacks quickly became household favorites, thanks to their light, crunchy texture and versatility as a base for sweet or savory flavors.

4.Technological Advancements in Maize Puff Making Machines

The latter half of the 20th century witnessed remarkable advancements in maize puff making machine technology. Manufacturers began to incorporate features like automated temperature and pressure controls, precise moisture meters, and customizable shaping molds. These innovations allowed for greater consistency in product quality, reduced waste, and increased production efficiency. Today’s maize puff making machines are marvels of engineering, capable of processing thousands of kilograms of corn per hour while maintaining uniformity in size, shape, and texture.

5.Modern Trends and Innovations

In recent years, the maize puffing industry has continued to evolve, driven by consumer demand for healthier, more sustainable snack options. Manufacturers are now exploring alternative ingredients, such as organic or non-GMO corn, and experimenting with innovative flavor profiles, including spicy, cheesy, and even plant-based varieties. Additionally, there is a growing focus on reducing energy consumption and waste in maize puff production, with many companies adopting eco-friendly practices and technologies.

6.A Legacy of Innovation

From its humble beginnings as a traditional cooking method to its current status as a cornerstone of the snack food industry, the history of maize puffing is a testament to human ingenuity and the power of innovation. The maize puff making machine has played a crucial role in this evolution, transforming corn kernels into the crispy, irresistible treats we enjoy today. As technology continues to advance, we can only imagine what the future holds for this beloved snack and the machines that make it possible.

Understanding the Maize Puff Making Process

The transformation of raw corn kernels into the light, crispy texture of maize puffs is a meticulously engineered process orchestrated by the maize puff making machine. At its core, this process involves a combination of heat, pressure, and moisture control, each element playing a pivotal role in achieving the desired product characteristics.

Kernel Preparation: The Foundation of Quality | The journey begins with selecting high-quality corn kernels, often non-GMO or organic varieties to meet modern consumer preferences for healthier snacks. These kernels undergo rigorous cleaning to remove debris, dust, and foreign particles. Advanced maize puff making machines may integrate optical sorters or magnetic separators to ensure only the purest kernels enter the production line. The cleaned kernels are then graded by size to guarantee uniform puffing, as inconsistent sizes can lead to uneven expansion during the cooking phase. |

Conditioning: Optimizing Moisture Content | Moisture is the key to puffing success. Corn kernels typically contain 12–15% moisture, but for puffing, this must be precisely adjusted to 18–22%. Conditioning systems within the maize puff making machine use steam injection or humidification chambers to gently raise the moisture content. This step is critical; too little moisture results in under-expanded, hard puffs, while too much can cause kernels to burst or stick together. Sophisticated moisture meters continuously monitor the kernels, ensuring the exact moisture level is maintained throughout the process. |

Cooking and Puffing: The Science of Expansion | The heart of the maize puff making machine is the cooking and puffing chamber, where science meets craftsmanship. Conditioned kernels are fed into a high-pressure, high-temperature environment, often reaching 200–250°C (392–482°F) and pressures up to 10 bar. As the kernels heat, the moisture inside rapidly vaporizes, creating steam that expands the starch molecules within the kernel. This expansion, known as "puffing," occurs in milliseconds, transforming the hard kernel into a porous, airy structure. |

Modern machines employ two primary puffing methods | Gun Puffing: Uses a sudden release of pressure to expand kernels, akin to popcorn but with greater control over texture. Extrusion Puffing: Forces kernels through a die under extreme pressure, resulting in uniform shapes like balls, rings, or stars. |

Shaping and Molding: Crafting the Perfect Crunch | Once puffed, the kernels enter a shaping and molding stage. Die plates or rotary molds within the maize puff making machine compress the expanded kernels into desired shapes, from classic spheres to innovative designs like stars or animals. This step not only enhances visual appeal but also ensures consistent portion sizes for packaging. Advanced machines can switch molds in seconds, allowing for rapid product line changes and customization. |

Drying and Cooling: Locking in Freshness | Post-puffing, the kernels are still fragile and retain residual moisture. The maize puff making machine routes them through a multi-stage drying and cooling system. Hot air blowers remove excess moisture, while ambient or chilled air stabilizes the product temperature. This step is crucial for preventing sogginess and extending shelf life, as moisture levels must drop below 5% to inhibit microbial growth. |

Flavoring and Coating: The Final Touch | The last phase of the maize puff making process adds the "delight" factor. Flavoring systems, whether spraying oil and seasoning blends or applying sugar coatings, are seamlessly integrated into the machine. Nitrogen-flushed drums or vibratory conveyors ensure even coating distribution, while infrared sensors monitor adherence levels. Innovations like electrostatic flavoring technology are emerging, offering more precise application and reduced waste. |

Quality Control: Ensuring Perfection | Throughout the process, the maize puff making machine incorporates real-time monitoring systems. Vision cameras inspect for shape defects, metal detectors screen for contaminants, and moisture analyzers verify final product specs. Any deviations trigger automated adjustments, ensuring every batch meets stringent quality standards. |

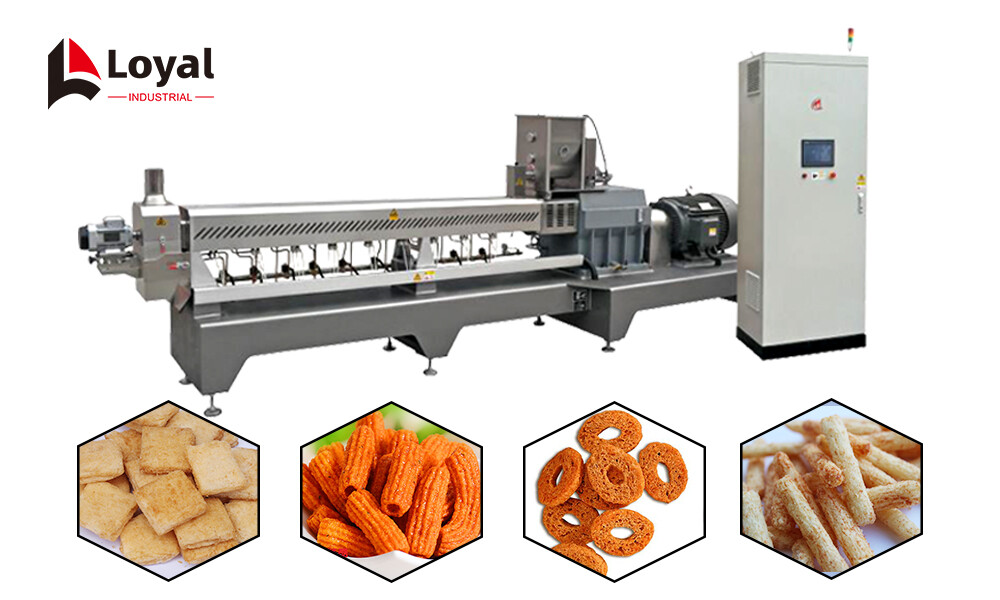

Types and Features of Maize Puff Making Machines

In the realm of industrial food processing, the maize puff making machine stands as a pivotal innovation, revolutionizing how corn kernels are transformed into the beloved crispy snacks enjoyed worldwide. These machines are engineered with precision to cater to diverse production scales and product specifications, ensuring consistency, efficiency, and quality in every batch.

1. Batch-Type Maize Puff Machines

Batch-type maize puff makers are ideal for small-scale operations or artisanal producers seeking flexibility in flavor and texture. These machines operate by loading a predetermined quantity of corn kernels into a sealed chamber, where heat and pressure are precisely controlled to achieve the desired expansion. Key features include adjustable temperature and pressure settings, allowing operators to customize puff characteristics such as density and crunchiness. Additionally, batch-type models often incorporate easy-clean designs to facilitate rapid changeovers between recipes.

2. Continuous-Flow Maize Puffing Systems

For large-scale industrial applications, continuous-flow maize puffing systems are the preferred choice. These high-capacity machines process corn kernels in a seamless, uninterrupted stream, significantly boosting productivity while maintaining uniformity in product quality. Advanced models feature automated feeding mechanisms, real-time monitoring of process parameters (e.g., moisture content, expansion ratio), and integrated cooling systems to stabilize puffed corn immediately after expansion. This ensures that the final product retains its light, airy texture and retains the nutritional integrity of the raw corn.

3. Twin-Screw Extrusion Puffers

A subset of continuous-flow systems, twin-screw extrusion puffers combine the principles of extrusion cooking with puffing technology. By subjecting corn dough (a mixture of corn flour, water, and optional additives) to intense heat, shear, and pressure within co-rotating twin screws, these machines produce puffed snacks with unique shapes, textures, and flavor profiles. The dual-screw design enhances mixing efficiency, enabling the incorporation of diverse ingredients such as spices, cheeses, or sweeteners directly into the dough matrix. Post-extrusion, the product is cut into desired shapes and dried to achieve the signature crispness of puffed corn snacks.

4. Microwave-Assisted Puffing Units

Emerging as a sustainable alternative to traditional heating methods, microwave-assisted puffing units leverage electromagnetic energy to rapidly heat and expand corn kernels. This technology reduces processing time and energy consumption while preserving the natural color, aroma, and nutrients of the corn. Microwave puffers are particularly suited for producing premium-quality snacks with a clean label appeal, as they eliminate the need for oil or chemical additives commonly used in conventional puffing processes.

Key Features Across All Types

Regardless of the specific design, modern maize puff making machines share several core features that define their performance and reliability:

Precision Temperature Control | Ensures optimal expansion without scorching or undercooking. |

Advanced Pressure Regulation | Maintains consistent kernel integrity and puff uniformity. |

Hygienic Design | Complies with food safety standards (e.g., FDA, HACCP) to prevent cross-contamination. |

Energy Efficiency | Incorporates insulation, heat recovery systems, or renewable energy sources to minimize operational costs. |

Automation & Connectivity | Offers PLC-based controls, data logging, and IoT integration for remote monitoring and predictive maintenance. |

Optimizing Maize Puff Production with the Right Machine

The journey from raw corn kernels to irresistibly crispy puffs hinges on selecting the optimal maize puff making machine tailored to specific production goals. In the competitive landscape of snack food manufacturing, efficiency, product quality, and cost-effectiveness are paramount, making machine selection a strategic decision with far-reaching implications. Here, we delve into the critical factors that food processors must consider to optimize maize puff production.

1. Capacity Alignment with Demand

The first step in optimizing production is aligning machine capacity with market demand. Batch-type puffers, ideal for small-scale or artisanal operations, offer flexibility in recipe development and rapid changeovers between flavors or textures. In contrast, continuous-flow systems, such as twin-screw extruders or microwave-assisted puffers, are engineered for high-volume output, capable of processing thousands of kilograms per hour. Choosing a machine with the right capacity ensures that production neither outpaces sales nor falls short of meeting consumer demand, thereby avoiding inventory bottlenecks or operational inefficiencies.

2. Precision Control for Consistency

Consistency is the hallmark of a successful maize puff brand. Advanced maize puff making machines incorporate precision control systems that regulate temperature, pressure, and moisture content to within narrow tolerances. For example, twin-screw extruders leverage co-rotating screws to achieve uniform mixing and shear, ensuring that every kernel expands uniformly. Similarly, microwave-assisted puffers use electromagnetic energy to heat corn kernels rapidly and evenly, minimizing variations in texture or color. These technologies not only enhance product quality but also reduce waste by minimizing off-spec batches.

3. Energy Efficiency and Sustainability

In an era of rising energy costs and environmental consciousness, the energy efficiency of a maize puff making machine is a critical consideration. Modern machines are designed with energy-saving features, such as heat recovery systems, insulation, and variable-frequency drives, to minimize power consumption. Additionally, microwave-assisted puffing offers a sustainable alternative to traditional heating methods, as it reduces processing time and eliminates the need for oil or chemical additives. By selecting an energy-efficient machine, food processors can lower operational costs while aligning with corporate sustainability goals.

4. Hygienic Design and Compliance

Food safety is non-negotiable in snack food manufacturing. Maize puff making machines must comply with stringent hygiene standards, such as FDA, HACCP, and GMP, to prevent cross-contamination and ensure product integrity. Features like stainless steel construction, smooth surfaces, and self-cleaning mechanisms facilitate easy sanitization, while hermetically sealed chambers and automated lubrication systems minimize the risk of microbial growth or equipment failure. Investing in a machine with robust hygienic design not only protects consumers but also safeguards a company’s reputation and regulatory compliance.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/