How To Choose The Best corn puffs machine: 2024 Buyer’s Guide

Introduction

In the bustling world of food processing, the quest for innovative and efficient machinery is ceaseless. Among the myriad of equipment that caters to the diverse needs of the food industry, the corn puffs machine stands out as a pivotal player in the production of crunchy, airy snacks beloved by consumers worldwide. As an industrial food machinery expert, I am here to guide you through the essentials of choosing the best corn puffs machine for your production needs in 2024.

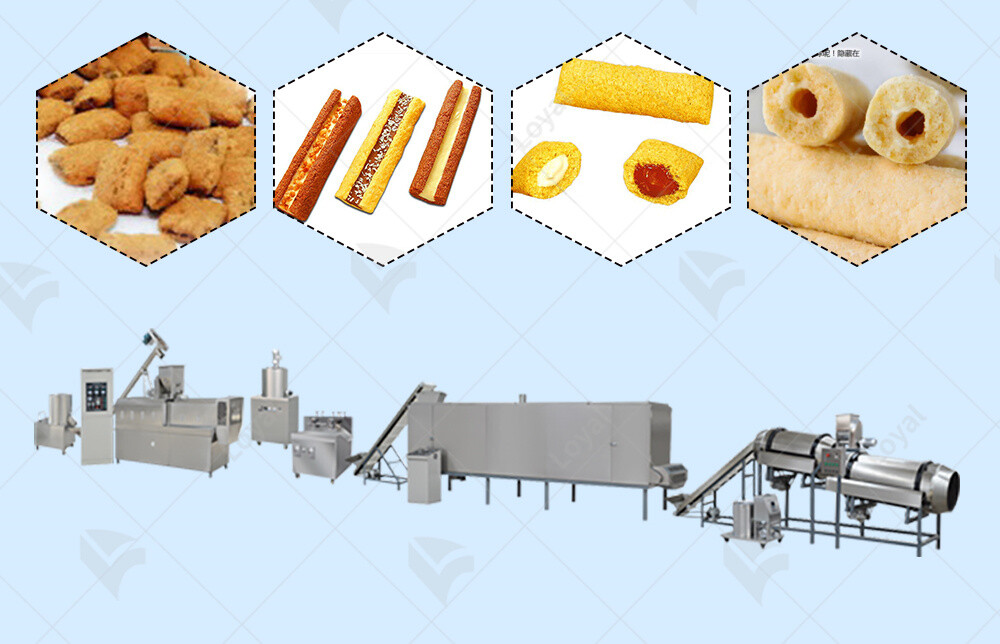

The corn puffs machine, also known as an extruder or puffing machine when applied to corn, is a specialized piece of equipment designed to transform raw cornmeal or other cereal grains into light, expanded snacks. This transformation occurs through a combination of heat, pressure, and mechanical shear forces, which are carefully controlled to achieve the desired texture and flavor profile.

The importance of selecting the right corn puffs machine cannot be overstated. It is not merely about producing a quantity of snacks but ensuring that each puff meets the highest standards of quality, taste, and consumer appeal. A well-chosen machine can significantly enhance your production efficiency, reduce operational costs, and ultimately boost your bottom line.

In this comprehensive buyer's guide, we will delve into the key factors to consider when choosing a corn puffs machine, explore the various types available in the market, and highlight some top brands and models that deserve your attention. By the end of this guide, you will be equipped with the knowledge and insights necessary to make an informed decision that aligns with your production goals and consumer preferences.

As we embark on this journey, it's crucial to keep in mind the ever-evolving landscape of food machinery technology. With advancements in automation, energy efficiency, and safety features, the options for corn puffs machines are more diverse and sophisticated than ever before. Staying ahead of the curve means staying informed, and this guide is your first step towards mastering the art and science of selecting the best corn puffs machine for your business.

Key Factors to Consider When Choosing a Corn Puffs Machine in 2024

Production Capacity and Efficiency

When selecting a corn puffs machine, the first factor to consider is its production capacity and efficiency. Depending on the scale of your operation, you'll need a machine that can meet your production demands without compromising quality. For small-scale businesses, a compact, manual machine might suffice. However, for large-scale operations, a fully automatic corn puffs machine with high production capacity is ideal.

Efficiency is another critical aspect. A well-designed machine should minimize downtime and waste, ensuring maximum output with minimal effort. Look for machines with advanced features such as automatic feeding, temperature control, and consistent extrusion rates to optimize production efficiency.

Machine Design and Durability

The design and durability of the corn puffs machine are also essential factors to consider. A sturdy, well-constructed machine is less likely to breakdown or require frequent repairs, reducing maintenance costs and downtime. Look for machines made from high-quality materials that can withstand the rigors of daily use.

Additionally, consider the machine's ergonomic design. A user-friendly interface and easy access to critical components can simplify maintenance and troubleshooting, ensuring smoother operations.

Automation Level and Ease of Operation

In today's fast-paced food industry, automation is a must. A highly automated corn puffs machine can significantly reduce labor costs and increase productivity. Look for machines with advanced automation features such as PLC controls, touchscreens, and remote monitoring capabilities.

Ease of operation is another critical factor. Even with advanced automation, the machine should be intuitive and easy to use. Training your staff on a complex machine can be time-consuming and costly, so opt for a machine with a straightforward interface and clear operating instructions.

Energy Efficiency and Cost-Effectiveness

Energy efficiency is a growing concern in the food industry, and it's essential to consider when choosing a corn puffs machine. A machine that consumes less energy will reduce your operational costs and your carbon footprint. Look for machines with energy-saving features such as variable frequency drives (VFDs) and efficient heating elements.

Cost-effectiveness is another key factor. While a high-end, fully automatic machine may have a higher upfront cost, it can often lead to significant savings in the long run due to increased production efficiency, reduced labor costs, and lower maintenance expenses.

Safety Features and Compliance with Standards

Safety should always be a top priority when choosing any industrial equipment, including corn puffs machines. Look for machines with robust safety features such as emergency stop buttons, interlocks, and protective guards to minimize the risk of accidents.

Compliance with industry standards is also crucial. Ensure the machine you choose meets all relevant safety and regulatory requirements, including those related to food safety and hygiene. This will help protect your business from potential legal issues and ensure that your products meet consumer expectations.

Types of Corn Puffs Machines Available in the Market

When it comes to corn puffs machines, there's a wide range of options to choose from, each tailored to meet different production requirements and budgets. Here's an overview of the three main types of corn puffs machines currently available in the market:

3.1. Small-Scale Manual Machines

For those just starting out or operating a small-scale business, small-scale manual machines are an excellent choice. These machines are designed for low-volume production and are easy to operate. They typically require manual feeding of corn kernels and hand-cranking to extrude the dough into puffs. While they may not offer the same efficiency as larger machines, they are cost-effective and perfect for testing the market or producing small batches for local sales.

One key advantage of small-scale manual machines is their portability. They are lightweight and can be easily transported, making them ideal for food vendors or entrepreneurs who participate in fairs, festivals, or other events. However, it's important to note that these machines may not be suitable for high-volume production or commercial use due to their limited capacity and manual operation.

3.2. Semi-Automatic Machines

Semi-automatic corn puffs machines offer a step up from manual machines, incorporating some automation to improve efficiency and productivity. These machines typically have an automated feeding system that simplifies the process of loading corn kernels into the extruder. Once the dough is extruded, it is then cut, shaped, and fried to create the final product.

Semi-automatic machines are ideal for businesses that need to increase production volumes while still maintaining a level of control over the process. They offer a good balance between cost and efficiency, making them a popular choice among medium-sized food manufacturers. Additionally, these machines are often equipped with adjustable settings, allowing operators to fine-tune the production process to suit their specific needs.

3.3. Fully Automatic Corn Puffs Machines

For businesses that require high-volume production, fully automatic corn puffs machines are the ultimate choice. These machines are designed for maximum efficiency and productivity, incorporating advanced automation and control systems to streamline the entire production process.

Fully automatic machines handle every aspect of production from feeding the corn kernels to extruding, cutting, shaping, frying, and packaging the final product. They are equipped with sensors and control systems that monitor and adjust the production process in real-time, ensuring consistent quality and minimizing waste.

One of the key benefits of fully automatic machines is their ability to reduce labor costs. With minimal human intervention required, businesses can save on staffing expenses and allocate resources more effectively. Additionally, these machines are often designed with energy-saving features, reducing operational costs and improving overall profitability.

However, it's important to note that fully automatic machines come with a higher price tag. They require a significant investment, but for businesses that need to produce large volumes of corn puffs consistently and efficiently, the benefits far outweigh the costs.

How to Evaluate and Compare Different Corn Puffs Machines

When it comes to choosing the best corn puffs machine for your production needs, evaluating and comparing different models and brands is crucial. As an industrial food machinery expert, I recommend focusing on key aspects such as performance, reliability, customer support, and cost. Below, I have prepared a detailed comparison between two leading brands: LOYAL and Brown, to help you make an informed decision.

Comparison Table: LOYAL vs. Brown Corn Puffs Machines

Aspect | LOYAL Corn Puffs Machine | Brown Corn Puffs Machine |

Production Capacity | High-capacity models available, suitable for large-scale production | Moderate to high-capacity models, suitable for various production scales |

Efficiency | Advanced technology ensures high efficiency and low energy consumption | Efficient but may require regular maintenance to maintain optimal performance |

Machine Design | Sturdy and durable design, easy to clean and maintain | Sleek and modern design, but may be less durable compared to LOYAL |

Automation Level | Fully automated models available, reducing labor costs and errors | Semi-automated to fully automated models available, depending on the model |

Ease of Operation | User-friendly interface and controls, suitable for both beginners and experts | Intuitive controls but may require some training for new operators |

Energy Efficiency | Energy-efficient motors and components, reducing operational costs | Good energy efficiency but may not match the latest energy-saving technologies |

Safety Features | Comprehensive safety features, ensuring operator safety and machine integrity | Basic safety features but may lack advanced safety technologies compared to LOYAL |

Customer Support | Dedicated customer support team, fast response times, and comprehensive after-sales service | Good customer support but may have longer response times during peak periods |

Warranty and Guarantee | Extended warranty periods and comprehensive guarantees for peace of mind | Standard warranty periods and guarantees, but may offer additional services at an extra cost |

Price Range | Competitive pricing, offering good value for money | Price varies depending on the model and features, but may be higher than LOYAL for similar specifications |

Evaluation Criteria Explained

Production Capacity: Look for a machine that can meet or exceed your production requirements. LOYAL offers high-capacity models suitable for large-scale production, while Brown provides a range of models suitable for various production scales.

Efficiency: Efficiency directly impacts your operational costs and profitability. LOYAL machines are designed with advanced technology to ensure high efficiency and low energy consumption. While Brown machines are also efficient, they may require regular maintenance to maintain optimal performance.

Machine Design: Durability and ease of maintenance are key factors in machine design. LOYAL machines feature a sturdy and durable design that is easy to clean and maintain. Brown machines have a sleek and modern design but may be less durable compared to LOYAL.

Automation Level: Automation can reduce labor costs and errors, improving overall productivity. LOYAL offers fully automated models that reduce the need for manual intervention. Brown provides semi-automated to fully automated models, depending on the specific model you choose.

Ease of Operation: User-friendliness is crucial for both beginners and experts. LOYAL machines have a user-friendly interface and controls, making them easy to operate. Brown machines have intuitive controls but may require some training for new operators.

Energy Efficiency: Energy efficiency is essential for reducing operational costs and environmental impact. LOYAL machines use energy-efficient motors and components to minimize energy consumption. Brown machines are also energy-efficient but may not match the latest energy-saving technologies.

Safety Features: Safety is paramount in any industrial setting. LOYAL machines come with comprehensive safety features that ensure operator safety and machine integrity. Brown machines have basic safety features but may lack advanced safety technologies compared to LOYAL.

Customer Support: Good customer support is crucial for addressing any issues or concerns you may have. LOYAL offers dedicated customer support with fast response times and comprehensive after-sales service. Brown also provides good customer support but may have longer response times during peak periods.

Warranty and Guarantee: An extended warranty and guarantee provide peace of mind and protect your investment. LOYAL offers extended warranty periods and comprehensive guarantees, while Brown provides standard warranty periods and guarantees but may offer additional services at an extra cost.

Conclusion

When selecting the best corn puffs machine in 2024, it's crucial to adopt a strategic and informed approach. As an industrial food machinery expert, I emphasize the importance of considering factors such as machine efficiency, capacity, automation levels, energy consumption, ease of maintenance, and overall durability. The corn puffs machine you choose should seamlessly integrate into your production line, enhancing not just output but also the quality of your corn puffs. In today's competitive market, where consumer demands are ever-evolving, investing in a state-of-the-art corn puffs machine can be a game-changer. By prioritizing machines that incorporate advanced technology and reliable performance, you ensure not only profitability but also a sustained competitive edge. Remember, the best corn puffs machine is not just about the initial cost; it's about long-term value and the ability to meet future market demands. Thus, conduct thorough research, consult with industry professionals, and make a decision that aligns with your business objectives for optimal success.

Reference

Here are five authoritative foreign websites related to industrial food machinery, along with their URLs:

1.ThomasNet

Website: https://www.thomasnet.com

2.MachineryTrader

Website: https://www.machinerytrader.com

3.Food Engineering:https://www.foodengineeringmag.com

4.Pack Expo:https://www.packexpo.com

5.DirectIndustry:https://www.directindustry.com