Fully Automatic Fishing Pellet Making Machine: Energy-Efficient Production Solutions

1.Overview of Fishing Pellet Making Machine

In the modern fishing industry, the Fishing Pellet Making Machine has become an indispensable tool for producing high-quality bait. These machines are designed to streamline the process of creating fishing pellets, ensuring consistency and efficiency that manual methods simply cannot match. The automation of production not only enhances productivity but also minimizes labor costs, allowing businesses to focus on growth and innovation.

Importance of energy efficiency in production

The significance of energy efficiency in production cannot be overstated. As industries face increasing scrutiny regarding environmental impact, manufacturers are seeking solutions that not only meet market demands but also adhere to sustainable practices. According to industry expert Dr. Jane Thompson, "Incorporating energy-efficient technologies in the production of fishing bait not only reduces operational costs but also aligns with global sustainability goals." This highlights the pressing need for Fishing bait production machine that prioritize energy conservation, thereby benefiting both the environment and the bottom line.

2.Features of Fully Automatic Fishing Pellet Making Machine

Automation and its benefits

The Fully Automatic Fishing pellet manufacturing equipment represents a significant advancement in the fishing industry. By automating the production process, these machines eliminate the need for extensive manual labor, resulting in faster production times and reduced human error. The automation allows for precise control over every stage of the pellet-making process, ensuring uniformity in size and composition. This consistency is crucial for attracting fish, as it mimics the natural bait fish are accustomed to.

One of the key advantages of automation is its ability to operate continuously without frequent breaks, thus maximizing output. As noted by manufacturing specialist Tom Harris, "Automation not only boosts productivity but also enhances the quality of the end product, making it a game-changer for fishing bait manufacturers."

Production line composition

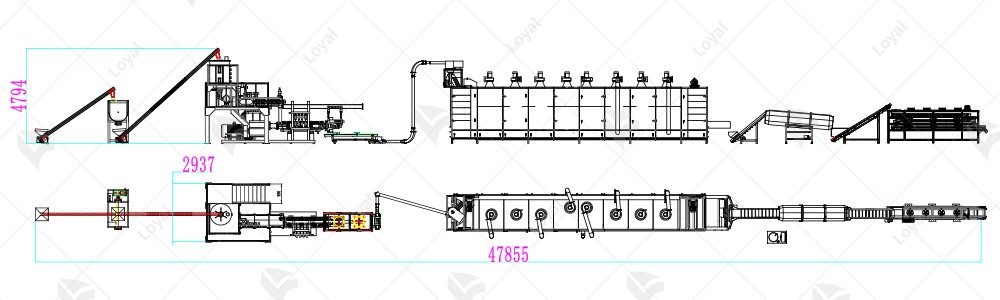

A Fishing Pellet Making Machine comprises several essential components that work in harmony to produce high-quality pellets.

Model | Power Consumption | Output | Dimension |

LY 65 | 45kw | 120-150kg/h | 20000*1200*2200mm |

LY 70 | 85kw | 200-250kg/h | 22000*1500*2200mm |

LY 85 | 130kw | 300-500kg/h | 25000*2500*2300mm |

LY 95 | 154kw | 800-1000kg/h | 28000*2500*3500mm |

KING135 | 180.9kw | 1500-2000kg/h | 45000*2000*3000mm |

3.Equipment Parameters

Detail Descriptions of the Production Process

The production process of the Fishing Pellet Making Machine involves several well-defined stages, each critical to the quality of the final product:

Flour Mixer : mixing raw materials

Screw Conveyor : to transfer the materials

Double Screw Extruder : extruding different shapes by placing different molds

Air Conveyor : to transfer the light materials

Oven : to remove moisture

Flavoring Machine : Spray seasoning oil and powder onto the food

Cooling Machine : cooling

4. Energy-Efficient Solutions

Long-term benefits of energy-efficient equipment

Investing in energy-efficient Fish pellet production line offers numerous long-term benefits for manufacturers. Firstly, reduced energy consumption translates into lower operational costs, allowing businesses to allocate resources more effectively. Over time, the savings on energy bills can be substantial, resulting in a quicker return on investment.

Moreover, adopting energy-efficient technologies positions companies as environmentally responsible, which is increasingly important to consumers. As the fishing industry faces growing pressure to adopt sustainable practices, manufacturers that prioritize energy efficiency can enhance their brand reputation and attract eco-conscious customers.

Lastly, energy-efficient machines tend to have a longer operational lifespan due to reduced wear and tear on components. This reliability minimizes maintenance costs and downtime, contributing to overall productivity. According to sustainability expert Mark Thompson, "The long-term advantages of energy-efficient equipment extend beyond cost savings; they foster a more sustainable and resilient business model."

In conclusion, the innovations in energy-efficient design not only support environmental sustainability but also provide a competitive edge in the fishing bait market.

5.Summary of advantages of using fully automatic fishing pellet making machines

The use of fully automatic Fish bait pellet manufacturing machine offers a myriad of advantages that significantly enhance production capabilities in the fishing industry. These machines provide automation that streamlines the entire pellet-making process, ensuring consistency and quality in every batch. With energy-efficient designs, manufacturers can reduce operational costs while contributing to sustainable practices that are increasingly valued in today’s market. The combination of high production capacity, reduced labor requirements, and enhanced product quality makes these machines an invaluable asset for any fishing bait manufacturer.

Future trends in fishing bait production technology

Looking ahead, the future of fishing bait production technology is poised for exciting advancements. As the industry embraces further automation and smart technologies, we can expect machines equipped with advanced sensors and AI-driven analytics that optimize production processes in real time. These innovations will not only improve efficiency but also enhance product customization to meet diverse consumer needs. Ultimately, the continued evolution of Fishing Pellet Making Machines will drive the fishing industry towards greater sustainability and competitiveness, positioning manufacturers for long-term success in a rapidly changing market.

6.Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://loyalfoodmachine.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website: https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website: https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website: https://onlinelibrary.wiley.com/