Fully Automatic Additives Microwave Sterilization Machine: Elevating Efficiency in Pasta Production

Introduction

Our company leverages cutting-edge technologies from Ispecc and Püschner to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Ispecc and Püschner, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Current Challenges in Pasta Sterilization

The pasta industry currently grapples with several challenges in traditional sterilization methods. One of the prominent issues is the limitation posed by conventional techniques in maintaining the delicate balance between preserving the quality of pasta products and achieving efficient sterilization. Traditional methods may fall short in addressing the increasing demand for faster production without compromising on the sensory attributes of pasta.

Additionally, the reliance on manual or semi-automated sterilization processes contributes to inconsistencies in the overall quality of pasta products. Achieving uniform sterilization across batches becomes a significant challenge, leading to variations in flavor, texture, and nutritional value.

Moreover, conventional methods may struggle to meet the evolving standards of efficiency and sustainability in pasta processing. With a growing emphasis on reducing energy consumption and enhancing production capacity, there is a need for innovative sterilization solutions that can address these challenges effectively.

The limitations of existing sterilization methods set the stage for the exploration of advanced technologies like Additives Microwave Sterilization Machine, as businesses seek to overcome these challenges and elevate the efficiency and quality of pasta production.Traditional pasta sterilization methods present challenges and limitations that hinder efficiency and quality. In this segment, we analyze these existing challenges, emphasizing the need for innovation and improved efficiency in pasta production. The narrative introduces the role of advanced technologies, specifically the Additives Microwave Sterilization Machine, as a transformative solution to address the shortcomings of traditional sterilization techniques.

Understanding Additives Microwave Sterilization Technology

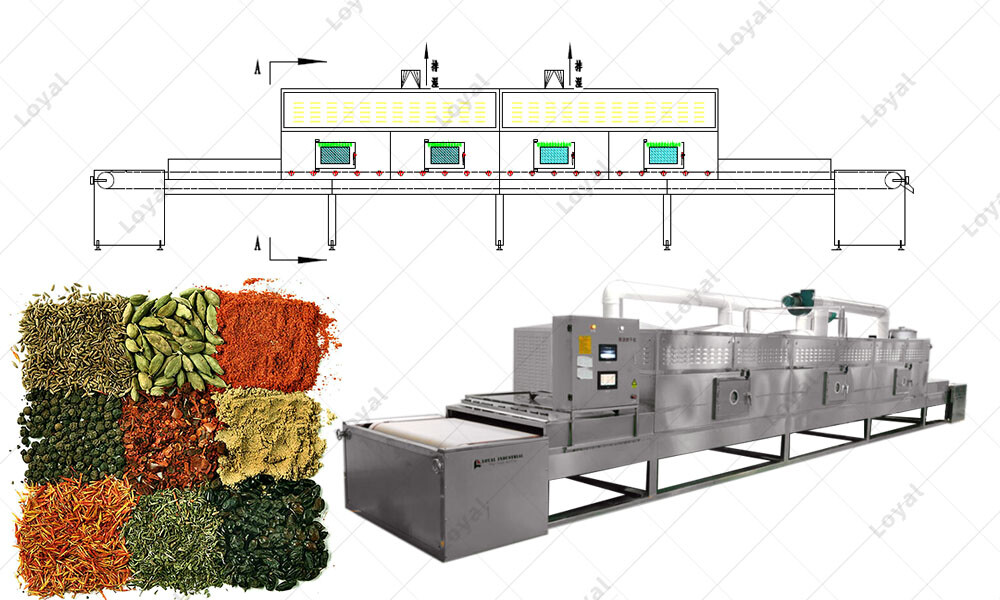

To comprehend the revolutionary shift in sterilization, we delve into the principles and mechanisms behind the Additives Microwave Sterilization Machine. This in-depth exploration includes a comparative analysis highlighting the machine's advantages over conventional sterilization methods. The discussion illustrates how this technology aligns with the overarching goals of elevating efficiency and maintaining superior product quality in pasta production.

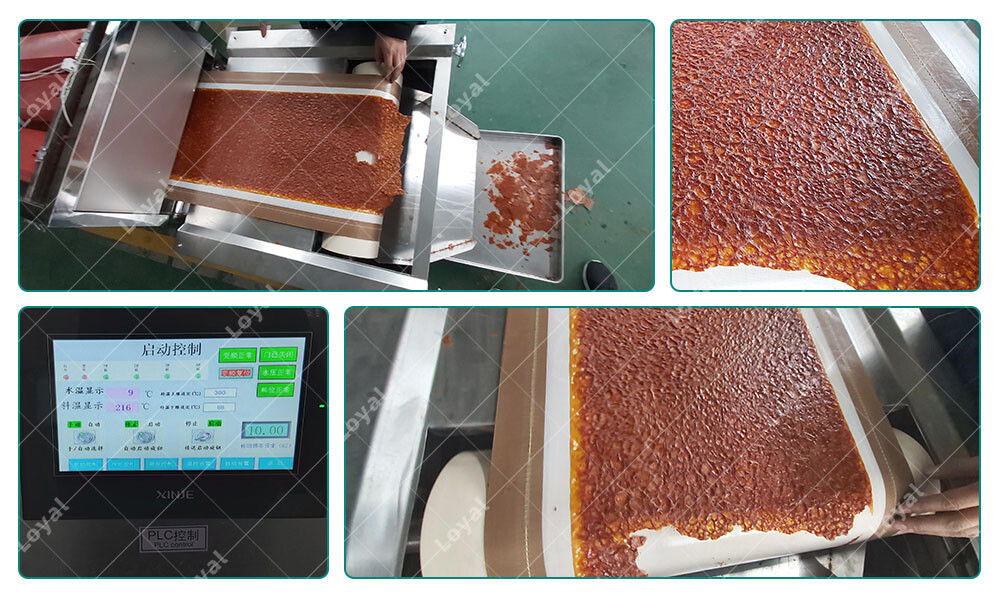

Technological Features of Fully Automatic Additives Microwave Sterilization Machine

The fully automatic Additives Microwave Sterilization Machine boasts a range of cutting-edge technological features that redefine the sterilization process in pasta production. The precision, speed, and overall efficiency of this innovative machine contribute significantly to enhancing the entire pasta processing system.

The machine is equipped with advanced sensors and control systems that ensure precise sterilization parameters.Automation allows for real-time adjustments, maintaining optimal conditions for different pasta varieties.

Leveraging microwave technology, the machine achieves swift sterilization, significantly reducing processing time.High-speed sterilization contributes to increased production capacity without compromising on quality.

The technology ensures uniform heating throughout the entire pasta batch, eliminating inconsistencies.This feature addresses challenges related to uneven sterilization common in traditional methods.

The machine incorporates energy-efficient components, aligning with the industry's sustainability goals.Reduced energy consumption contributes to cost-effectiveness and environmental responsibility.

Intuitive controls and a user-friendly interface make operation accessible for pasta production personnel.The machine is designed to streamline the sterilization process, minimizing the need for extensive training.

Real-world Applications and Success Stories

Through real-world case studies, testimonials, and success stories, we illustrate the practical applications of the Fully Automatic Additives Microwave Sterilization Machine in pasta production. These examples highlight quantifiable improvements in efficiency, quality, and overall pasta processing, providing tangible evidence of the transformative impact this technology has on the industry.

Advantages for the Pasta Industry

Examining the tangible benefits experienced by pasta producers through the adoption of fully automatic Additives Microwave Sterilization, we uncover a range of advantages. The technology ensures the preservation of flavor, texture, and nutritional value in pasta products, contributing to enhanced consumer satisfaction. Additionally, it facilitates increased production capacity, reduced processing time, and an overall elevation in the quality of pasta products.

Overcoming Challenges in Implementation

Implementing fully automatic Additives Microwave Sterilization Machine comes with its set of challenges. In this section, we identify these challenges and provide effective solutions to overcome potential obstacles. Strategies for a seamless integration process in pasta production facilities are explored, ensuring a smooth transition to this innovative technology without compromising ongoing operations.

Regulatory Compliance and Safety Standards

Navigating the regulatory landscape is critical in the pasta industry. This section delves into the importance of meeting regulatory requirements, with a specific focus on how fully automatic Additives Microwave Sterilization ensures compliance with safety standards. Collaboration with regulatory authorities is emphasized to establish industry best practices, ensuring that the adoption of this technology aligns with established safety and quality norms.

Future Trends and Innovations

As we explore the anticipated trends in the continued application of fully automatic Additives Microwave Sterilization, we uncover innovations on the horizon that could further enhance efficiency and sustainability in pasta processing. This section provides insights into how technology will shape the future of the pasta production industry, pointing towards a path of continuous improvement and innovation.

Conclusion

Summarizing key points regarding the impact of fully automatic Additives Microwave Sterilization on pasta production efficiency, this section offers a reflective conclusion. It encourages businesses to adopt innovative technologies for enhanced quality, efficiency, and safety in pasta processing. The forward-looking perspective underscores the ongoing evolution of sterilization practices in the pasta production industry, paving the way for a dynamic and progressive future.

About Additives Microwave Sterilization Machine

This section addresses common questions about Additives Microwave Sterilization Machine, providing clarity on its functionality, benefits, and implementation. FAQs serve to enhance understanding and offer practical insights for businesses considering the adoption of this advanced sterilization technology.