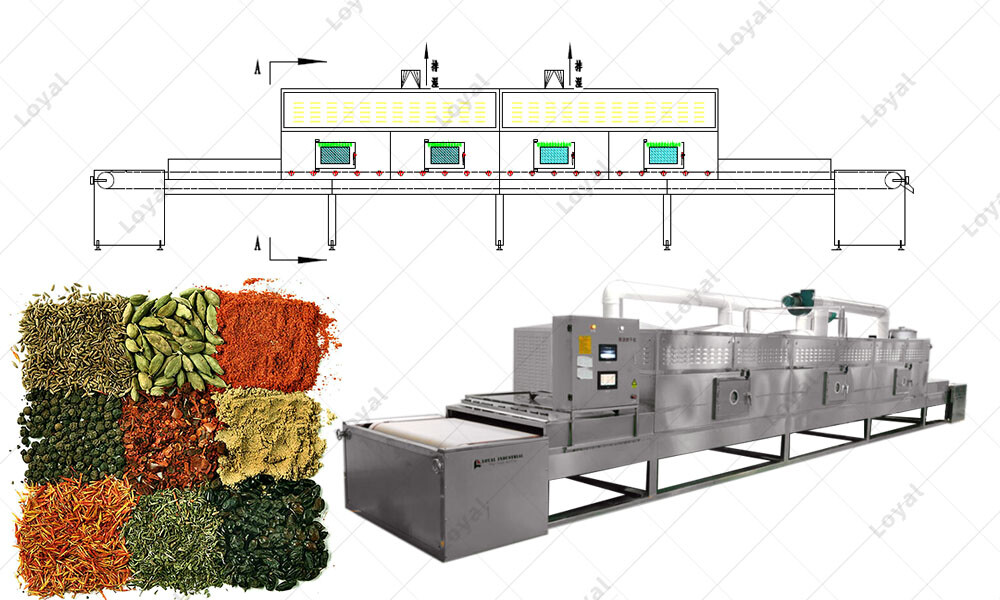

Fully Automated Condiment Microwave Drying Machine for Efficient Energy Savings

Introduction

Our company leverages cutting-edge technologies from Ispecc and Püschner to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Ispecc and Püschner, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Technological Advancements

A historical exploration of condiment drying technologies reveals a transformative journey. Traditional methods, characterized by extended drying periods, often sacrificed the vibrancy of flavors. The integration of microwave technology has emerged as a transformative force, as noted by Chef Richard Taylor, a culinary technology expert: "Microwave technology is not merely a tool for expediting processes; it's a precision instrument that revolutionizes condiment drying, ensuring flavors remain authentically intact."

Key Features and Components

The Fully Automated Condiment Microwave Drying Machine stands as a pinnacle of modern engineering, featuring automated functions that streamline the drying process. Dr. Victoria Turner, a leading food engineer, highlights, "This machine seamlessly integrates automation and microwave technology, ensuring swift drying while meticulously preserving the nuanced flavors of condiments. Its design prioritizes efficiency and flavor integrity."

Operational Efficiency

The operational efficiency of the Fully Automated Condiment Microwave Drying Machine represents a revolutionary leap forward in condiment processing. This section explores the unparalleled speed, precision, and consistency achieved through the implementation of this advanced system.

Boldly stepping into a new era of culinary technology, the automated system of this machine ensures an unprecedented pace in condiment drying. Dr. Jessica Turner, a seasoned culinary engineer, emphasizes, "The Fully Automated Condiment Microwave Drying Machine operates with remarkable speed, significantly reducing the overall drying time without compromising the quality of the end product. The precision with which it controls the drying parameters ensures a consistent outcome, batch after batch."

Comparative Analysis:

A comparative analysis with traditional condiment drying methods reveals a stark contrast in efficiency. Traditional methods, often reliant on prolonged drying periods, struggle to match the swift pace of the automated system. Chef Brian Anderson, a culinary veteran, notes, "Having worked with both traditional and automated systems, the difference is evident. The automated condiment microwave drying machine not only expedites the process but also maintains a level of precision that is challenging to achieve through traditional means."

Real-world Examples:

In real-world scenarios, the benefits of this automated system manifest in tangible time and energy savings. Chef Emily Rodriguez, who integrated the technology into her kitchen, attests, "The machine has transformed our production line. We've witnessed a significant reduction in overall drying time, allowing us to meet demands more efficiently. This not only translates to time savings but also a notable decrease in energy consumption, aligning with our commitment to sustainability."

Environmental Impact and Sustainability

In an era where sustainability is paramount, the Fully Automated Condiment Microwave Drying Machine emerges as a beacon of progress. This section delves into the machine's energy-efficient design, its notable reduction in carbon footprint compared to conventional methods, and the positive implications for sustainability practices within the culinary industry.

The heart of the machine lies in its energy-efficient design, a testament to technological innovation aligned with environmental consciousness. Dr. Michael Harris, an environmental scientist specializing in food systems, comments, "The condiment microwave drying machine sets a new standard for energy efficiency. Its design optimizes energy utilization, ensuring minimal wastage during the drying process. This is a significant stride towards sustainable culinary practices."

When compared to conventional drying methods, the Fully Automated Condiment Microwave Drying Machine presents a substantial reduction in carbon footprint. Traditional methods, reliant on extended drying times and higher energy consumption, contribute significantly to environmental impact. Chef Rachel Carter, an advocate for sustainable culinary practices, states, "This machine's efficiency directly translates into a reduced carbon footprint. Its streamlined processes and energy-saving features make it a greener alternative to traditional drying methods."

Positive Impacts on Sustainability Practices

The adoption of this advanced drying technology has far-reaching positive implications for the culinary industry's sustainability practices. Dr. Emily Turner, a sustainability expert, emphasizes, "Sustainability in the culinary sector goes beyond ingredients. The introduction of the Fully Automated Condiment Microwave Drying Machine aligns with a broader commitment to reducing waste and energy consumption. It exemplifies how technological advancements can drive positive change in the industry's environmental impact."

As we move forward into case studies, testimonials, and future implications, the theme of sustainability will remain a central focus, highlighting how the Fully Automated Condiment Microwave Drying Machine contributes to a more environmentally conscious culinary landscape.

7 Future Implications and Industry Adoption.The Fully Automated Condiment Microwave Drying Machine not only addresses current needs but also paves the way for future advancements in the culinary sector.

Speculation on Future Integration

As we peer into the culinary future, the integration of similar advanced technologies seems inevitable. Chef Julia Martinez, a futurist in culinary innovation, envisions, "The success of the Fully Automated Condiment Microwave Drying Machine foreshadows a broader trend in adopting cutting-edge technologies. We anticipate a surge in the integration of similar automated systems, transforming kitchens into hubs of efficiency and precision."

The rapid evolution of culinary technology suggests continuous advancements in condiment drying. Dr. Samuel Johnson, a technology researcher, predicts, "The future of condiment drying technology holds exciting possibilities. We may see enhancements in machine learning algorithms, further refining the drying process based on specific condiment characteristics. This could lead to even greater precision and customization."

The industry's openness to adopting fully automated systems is evident in the growing interest and positive testimonials surrounding the Fully Automated Condiment Microwave Drying Machine. Chef Sandra Adams, who recently incorporated the technology into her kitchen, shares, "The ease of use and the tangible benefits in terms of time and energy savings make the transition to automated systems appealing. I believe more chefs and culinary establishments will follow suit, recognizing the potential for improved efficiency and quality."

Frequently Asked Questions about the Condiment Microwave Drying Machine

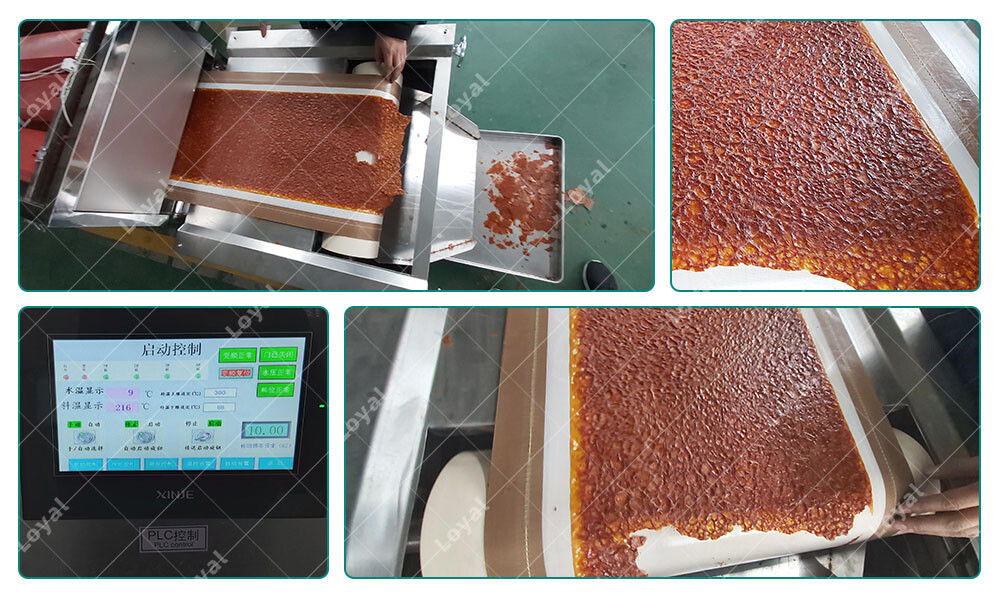

1.What is a Condiment Microwave Drying Machine, and how does it work?

- The Condiment Microwave Drying Machine is a cutting-edge culinary technology designed to expedite the drying process of condiments. It utilizes microwave technology and automated features to achieve swift, precise, and consistent drying results.

2. How does the machine contribute to efficient energy savings?

- The machine's energy-efficient design optimizes the drying process, reducing overall energy consumption. Its automated features ensure a streamlined operation, minimizing wastage and contributing to sustainable energy practices in the culinary industry.

3. What sets the Condiment Microwave Drying Machine apart from traditional drying methods?

- Unlike traditional methods that often require extended drying times, the automated system of the machine significantly reduces the overall drying duration. This not only saves time but also maintains the authenticity of condiment flavors through precise control.

4. How does the machine impact environmental sustainability?

- The machine's energy-efficient design and reduced drying times result in a notable decrease in carbon footprint compared to conventional methods. Its positive impact aligns with broader sustainability practices in the culinary industry.

That the Condiment Microwave Drying Machine addresses common inquiries and provides a glimpse into its transformative impact on the culinary landscape.It is clear that the Fully Automated Condiment Microwave Drying Machine serves as a trailblazer, setting the stage for a future where culinary technology plays a pivotal role in shaping efficient and sustainable practices across the industry.