Industrial Automatic Continuous Frying Line, Multifunctional Conveyor Fryer Machine

The frying system production line is made of food-grade stainless steel, with very reliable quality, durable and not easy to damage, can be used for a long time, and stainless steel in contact with food, will not cause pollution to the food, with a very high-quality standard of hygiene.

Industrial Automatic Continuous Frying Line, Multifunctional Conveyor Fryer Machine Specifications :

| Price | Contact us |

| Brand Name | LOYAL |

| Place of Origin | Shandong China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 20 days |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

Industrial Automatic Continuous Frying Line, Multifunctional Conveyor Fryer Machine Detail Introduction :

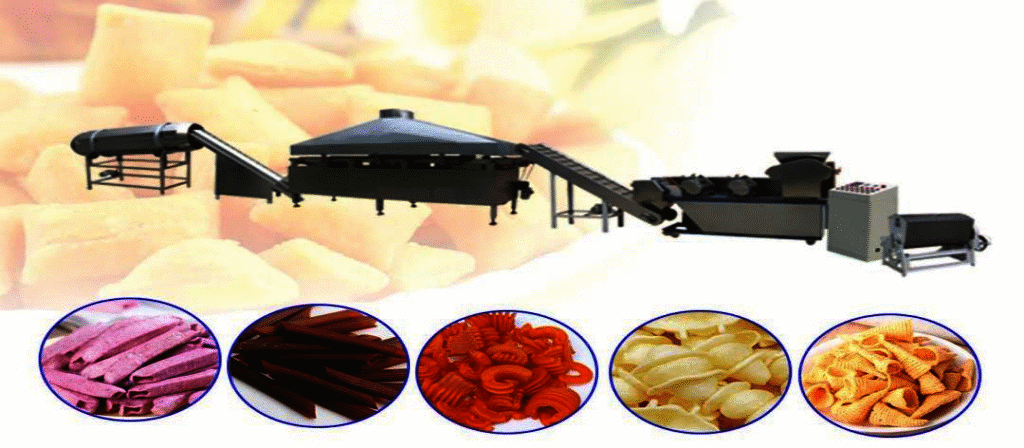

Automatic industrial continuous food frying production line produces continuous conveyor fryer. The fryer is an efficient and easy-to-operate machine, used for batch frying and continuous frying in the industrial production of snack foods. Automatic continuous frying line project: Fried food is more and more popular in market because of its good taste. It can make food crispy taste, it can make food good appearance, it’s also good for healthy.

We are the professional manufacturer of the automatic continuous frying line, basic on customer’s demands, we designed top quality whole line solution for satisfying different capacity demands.

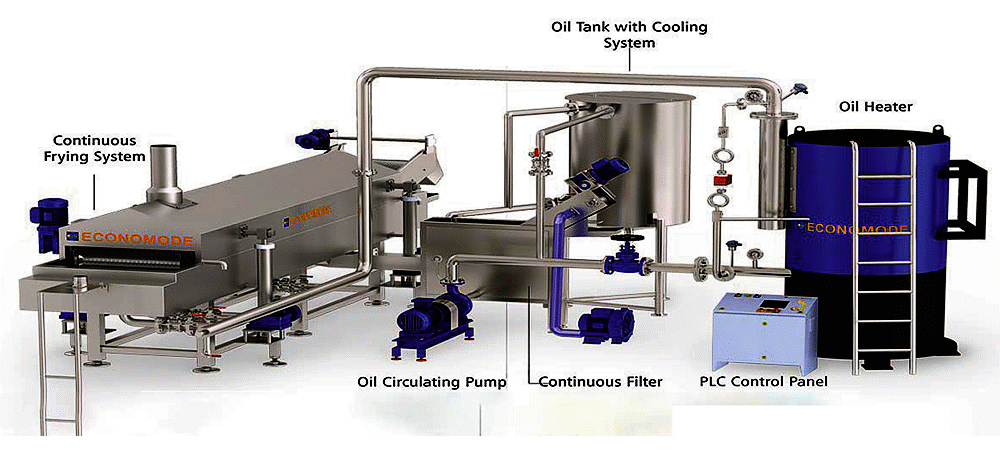

MAIN EQUIPMENT OF AUTOMATIC CONTINUOUS FRYING LINE

Continuous fryers equipment composed of several systems: wire belt convening system, wire belt lifting system, oil temperature control system, and oil circulatory system.

The plantain chips frying machine can use coal, gas, oil, electric heating and other heating methods to realize fully automatic industrial production. This production line is mainly used for frying raw materials such as puffed food, pasta and meat products.

TECHNICAL PARAMETERS OF AUTOMATIC CONTINUOUS FRYING LINE

| Model | Heating Power | Heating Temperature | Output | Size (L*W*H) |

| LYCF-L(electric fryer) | 97kw/h | ~250℃ | 300kg/h | 3000x1200x2100mm |

| LYCF-G (Gas/Diesel) | 6-20.5m³/h(Gas)7-15kg/h(Diesel) | ~250℃ | 300kg/h | 3000x1200x2100mm |

| LYCF-L-2 (electric fryer) | 122kw/h | ~250℃ | 400-500kg/h | 4000x1300x2200mm |

| LYCF-G-2 (Gas/Diesel) | 35m³/h(Gas)8-41kg/h (Diesel) | ~250℃ | 400-500kg/h | 4000x1300x2200mm |

THE MAIN ADVANTAGES OF AUTOMATIC CONTINUOUS FRYER

| 1 | Machine construction in stainless steel. |

| 2 | Automatic oil temperature control and power leakage protection devices.The machine will cut off electric automatically and give an alarm when over temperature. |

| 3 | Automatic oil level control |

| 4 | The belt transmission adopts frequency conversion speed regulation. The frying time is controllable. |

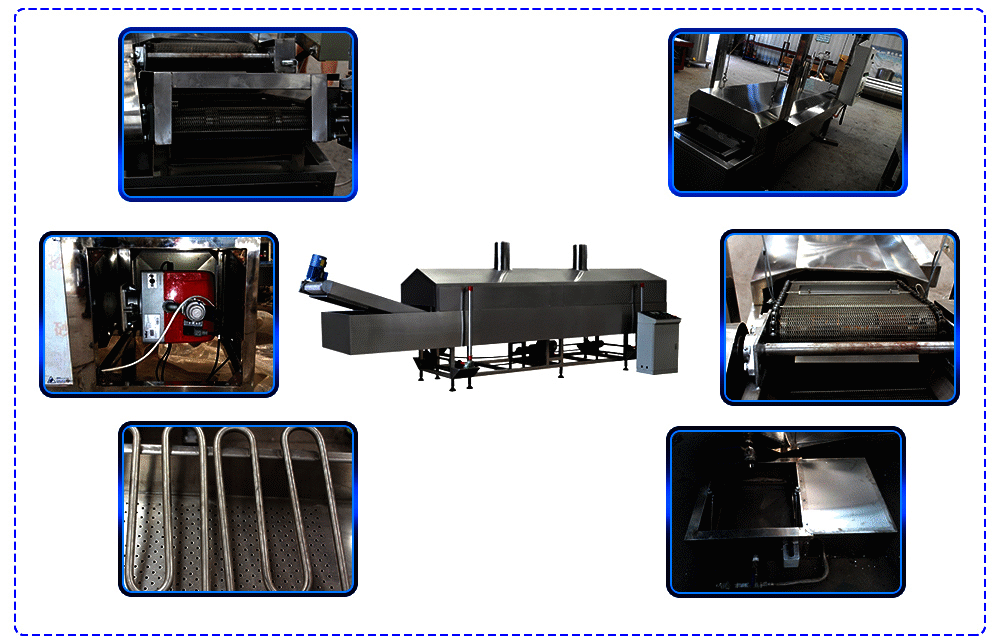

| 5 | The fryer is equipped with an automatic lifting system, an upper cover and a belt that can be lifted and lowered for easy cleaning. |

| 6 | There is a slagging system at the bottom, and the residue generated at any time is discharged. |

| 7 | The upper and lower double-layer mesh belts are used for transmission, and the product is sandwiched between the double-layer mesh belts to prevent the product from floating. |

| 8 | The double mesh belt shifting adjustment ensures the different frying time of the fry, and ensures that the fry is smoothly heated and transported at 2 to 3 cm below the oil layer; |

| 9 | With the gantry and lifting mechanism, the cover can be easily lifted and lowered for easy frying of food. |

| 10 | The fryer can be equipped with an oil circulation filtration system to continuously filter the oil residue during the production process, reduce the acid value of the oil, restore the color of the oil, and prolong the service life of the edible oil. |

DETAILED MAIN EQUIPMENT PICTURE OF AUTOMATIC CONTINUOUS FRYING LINE

The belt operation is changed by the speed regulating motor. After the chain and the chain gears and the gear transmission, the speed of the mesh belt can be adjusted. The frying time of different products is different.The continuous fryers equipment has lifting device for easy cleaning, and the cover collects smoke to exclude the outside (can connect the chimney to the outside).

The Commercial snack fryer machine can use electricity, oil, gas and coal heating. To prevent excess oil oxidation, our frying machines heat central section of oil layer, and control the temperature of upper and lower layer oil. Continuous deep fat fryer have double layer belt, can fry the products evenly, the products frying between two layers of wire belts, so that they can not run away freely. The stainless steel wire belt can transport the products with adjustable speeds.o prolong the oil's life span, our continuous fryer machine can automatically filter the oil, control the oil's temperature during the continuous food fryers process.

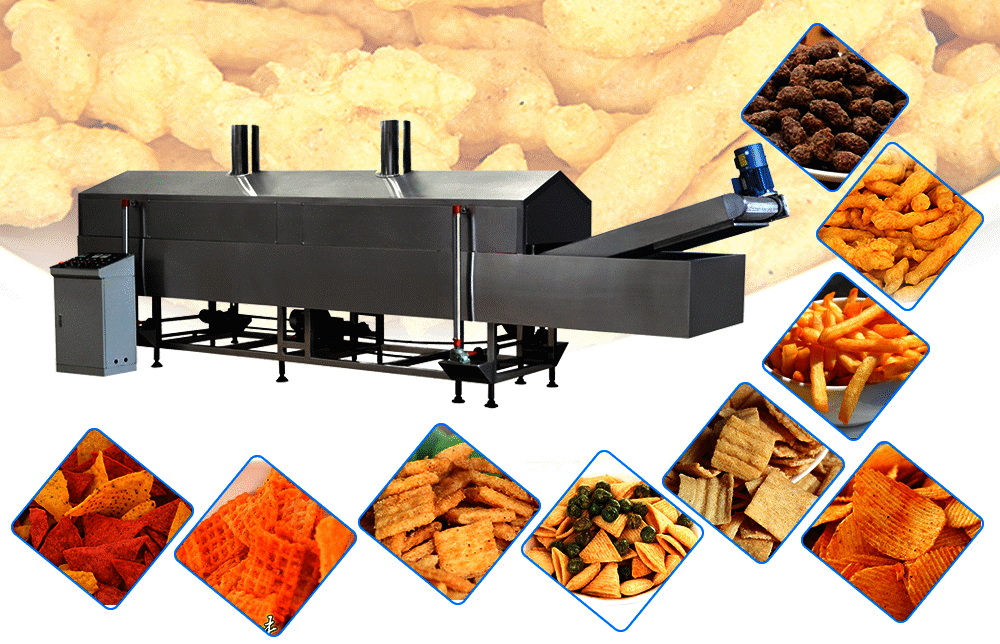

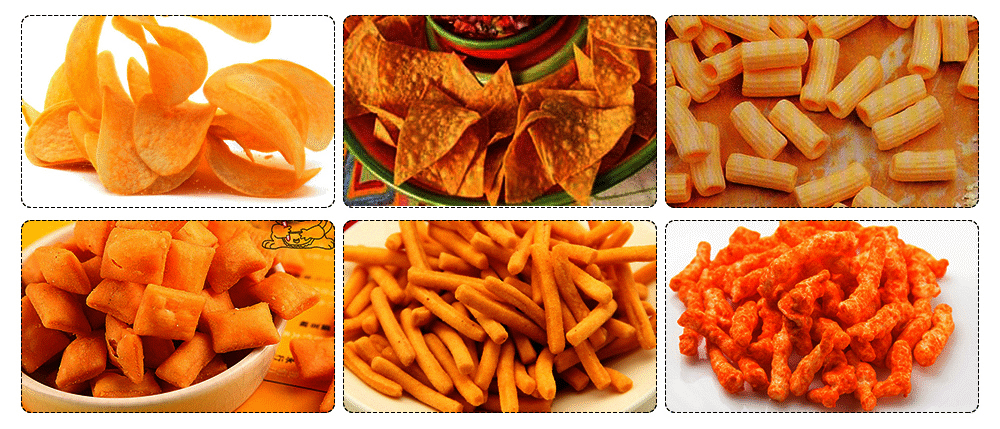

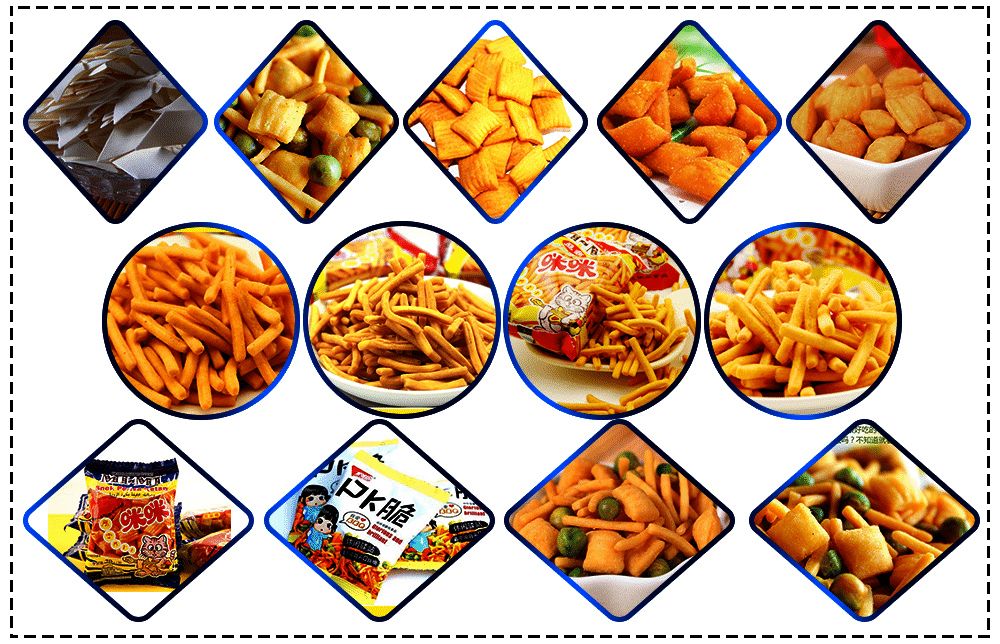

APPLICATIONS OF AUTOMATIC CONTINUOUS FRYING LINE

Automatic continuous frying line is used to fry potato chips, doritos chips, fried snacks, french fries, peanuts, onions, chicken meats, pellet snacks, kurkure, Nik Naks, chataka pataka, Twisties, Bingo and many other foods. China Industrial Fryer manufacturer have many experience and rich knowledge, can provide you customized commercial continuous fryer machines according to your needs and requirements.

1. Cooked wheaten food: fried dough twist: rice crust, honey food, honey mito, deep-fried dough sticks, fried glutinous rice balls with sesame, gluten, polished glutinous rice stick, caramel treats, thin fried dough twist, etc.

2. Meat: braised chicken (coloring), pressed salted duck (coloring), braised pork, ball, sliced dried beef, streaky pork, drumstick, pig's feet, etc.

3. Nut fruits: groundnut kernels, green soya bean, broad bean, sunflower seed.

4. Bean products: dried tofu, bean curd, fish bean curd, bread made by tofu.

5. Marine food products: various fish, peeled prawns, scallop, squid rings, squid.

6. Miscellaneous: vegetable pie, tempura, eggplant box, lotus root box, various fried puffed food with syrup and paste.

COMPANY INTRODUCTION

We are a reliable factory located in the beautiful spring city of Jinan, China.

We have a complete management system ISO9001.

We are the largest food processing machinery manufacturer in Jinan, the main products: pet food machinery, snack fryer machinery, fruit and vegetable cleaning and processing machinery, biscuit machinery, instant noodle machinery, pasta machinery, etc. food processing machinery manufacturers!

More than 20 engineers have more than 8 years of work experience and have traveled to more than 50 countries and regions.

Provide 24-hour telephone mail service to provide you with timely and feasible solutions and better after-sales service.

As a continuous fryer manufacturer before sales service for continuous fryers:

1.We provide you the suitable continuous food fryers solution,which is useful and convenient.

2.We produced the continuous deep fryer you need in our factory,you can buy it without any hesitate.

3.We provide you the factory design automatic continuous fryer processing line layout and also design for water and electric and gas etc.

4.With much experienced technical team, we can meet customer personalized requirement,produce the customized industrial continuous fryer for you.

Loyal’s service:

| High-quality after-sales service | Engineer services for overseas machinery services |

| 1.The distribution map requested by the buyer will be provided. 2.Process operation manual will be provided after delivery. 3.Provide 1 year complete warranty and lifetime maintenance services. 4.Free fragile spare parts will be sent out with the packing box. 5.The first installation can be completed by the equipped engineer. | 1.Provide free consultation service before, during and after sale. 2.Free project planning and design services. 3.Free debugging of equipment until everything is normal. 4.Free equipment maintenance and personal operation training. 5.Provide free new production process and formula. |