Everything You Need To Know Aboutdouble screw extruder machine

Introduction to the Double Screw Extruder Machine

In the realm of food manufacturing, technological advancements have continually reshaped the industry, driving efficiency, quality, and innovation. Among these advancements, the double screw extruder machinehas emerged as a cornerstone in the evolution of industrial food machinery. As an industrial food machinery expert, I am excited to introduce you to this remarkable piece of equipment, which has revolutionized manufacturing processes in the food industry.

The double screw extruder machine, often abbreviated as a twin-screw extruder, represents a significant leap forward in extrusion technology. Unlike single-screw extruders, which rely on a single rotating screw to process materials, the double screw extruder machine utilizes two intermeshing screws that work in harmony to convey, compress, and shape food materials with unparalleled precision and efficiency. This design allows for a more uniform distribution of shear and heat, resulting in improved product quality and consistency.

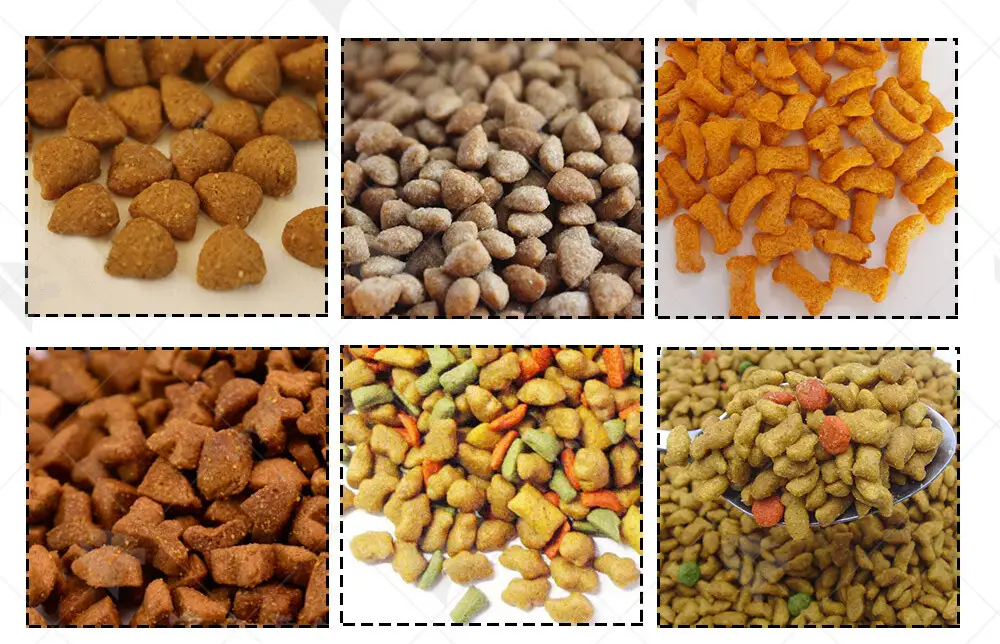

One of the most striking features of the double screw extruder machine is its versatility. This machinery can process a wide array of food ingredients, from grains and starches to proteins and fats. The ability to handle such a diverse range of materials makes the double screw extruder machine an invaluable asset in the production of various food products, including snacks, breakfast cereals, pet foods, and even texturized vegetable proteins. This versatility not only expands the range of products that can be manufactured but also allows for the creation of innovative and customized food items tailored to meet consumer demands.

Moreover, the double screw extruder machine excels in terms of process control. Advanced control systems and automation capabilities enable manufacturers to monitor and adjust the extrusion process in real-time, ensuring optimal production conditions. This level of precision is crucial in the food industry, where product quality, safety, and consistency are paramount. The double screw extruder machine's ability to deliver consistent outcomes, regardless of the material being processed or the desired product characteristics, is a testament to its engineering excellence and technological sophistication.

In summary, the double screw extruder machine represents a significant advancement in food manufacturing technology. Its versatility, precision, and efficiency make it an indispensable tool for food producers across the globe. As we continue to explore the potential of this remarkable machinery, we can expect to see even more innovative and groundbreaking applications in the food industry. Stay tuned for future insights on how the double screw extruder machine is shaping the future of food manufacturing.

Key Features and Benefits of Modern Double Screw Extruder Machines

These advanced machines offer a multitude of features and benefits that have revolutionized the way food products are produced. Let's delve into the key features and benefits of modern double screw extruder machines, highlighting how they are shaping the future of the food industry.

Advanced Design for Optimal Performance | Modern double screw extruder machines are designed with cutting-edge technology that enhances their performance and reliability. The intermeshing screws are precision-engineered to ensure smooth and efficient material conveyance, compression, and shaping. This advanced design allows for better control over the extrusion process, enabling manufacturers to produce food products with consistent quality and texture. Moreover, the screws are typically made from high-quality, wear-resistant materials that can withstand the rigors of continuous operation. This durability ensures that the double screw extruder machine remains a reliable and cost-effective investment for food producers. |

Versatile Material Handling Capabilities | One of the most notable features of modern double screw extruder machines is their versatility in handling a wide range of food materials. From starches and flours to proteins and fats, these machines can process a diverse array of ingredients with ease. This versatility makes them ideal for use in various food manufacturing applications, such as snack production, breakfast cereal manufacturing, and pet food formulation. The ability to process different types of materials without the need for significant modifications or adjustments underscores the flexibility and adaptability of modern double screw extruder machines. This feature is particularly advantageous for food producers who need to switch between different product lines or respond to changing consumer demands. |

Enhanced Process Control and Automation | Modern double screw extruder machines are equipped with advanced control systems and automation capabilities that provide manufacturers with unprecedented levels of process control. These systems enable real-time monitoring and adjustment of the extrusion process, ensuring optimal production conditions and product quality. Automation features, such as automated feeding systems and PLC-based control panels, further streamline the manufacturing process, reducing labor costs and minimizing human error. This level of precision and control is crucial in the food industry, where product safety, consistency, and traceability are of utmost importance. |

Sustainable Manufacturing Practices | In today's world, sustainable manufacturing practices are becoming increasingly important. Modern double screw extruder machines are designed with energy efficiency and environmental sustainability in mind. These machines typically consume less energy compared to traditional extrusion technologies, reducing operational costs and minimizing environmental impact. Furthermore, the ability to process a wide range of materials, including by-products and alternative ingredients, allows food producers to develop more sustainable product formulations. This, in turn, contributes to reducing food waste and promoting a circular economy within the food industry. |

Applications of the Double Screw Extruder Machine in Various Industries

The double screw extruder machine has emerged as a pivotal piece of equipment in the food manufacturing industry, revolutionizing production processes and enhancing product quality. However, its applications extend beyond the food sector, finding use in various industries where material processing and shaping are crucial.Let's explore some of the notable applications of these machines in various industries.

1.Food Manufacturing

In the food industry, double screw extruder machines are indispensable for producing a wide range of products. From snacks and breakfast cereals to pet food and meat substitutes, these machines offer precise control over the extrusion process, enabling manufacturers to create textures, shapes, and sizes that meet consumer demands. The ability to process a variety of ingredients, including starches, proteins, and fats, makes double screw extruder machines highly versatile in food production.

Moreover, the machines' energy efficiency and commitment to sustainable manufacturing practices align with the growing trend of eco-friendly food production. By minimizing waste and optimizing resource use, double screw extruder machines contribute to a more sustainable food industry.

2.Plastics and Polymers

Beyond the food sector, double screw extruder machines play a crucial role in the plastics and polymers industry. They are used for the compounding, mixing, and shaping of plastic materials, such as polyethylene, polypropylene, and PVC. The intermeshing screws provide efficient mixing and melting of the plastic resin, ensuring uniform distribution of additives and fillers.

In addition, double screw extruder machines are employed in the production of plastic pipes, films, and sheets. Their precision and control over the extrusion process make them ideal for creating products with specific physical and mechanical properties.

3.Pharmaceuticals

The pharmaceutical industry also benefits from the use of double screw extruder machines. These machines are used for the granulation, coating, and encapsulation of pharmaceutical products. The ability to process a wide range of materials, including active pharmaceutical ingredients (APIs) and excipients, makes double screw extruder machines versatile in pharmaceutical manufacturing.

Furthermore, the machines' precision and control over the extrusion process ensure consistent product quality and uniformity, which are crucial factors in pharmaceutical production. By minimizing variability and enhancing product performance, double screw extruder machines contribute to the development of safe and effective pharmaceutical products.

In conclusion, the double screw extruder machine is a versatile and adaptable piece of equipment with a wide range of applications across various industries. From food manufacturing to plastics and polymers, and even pharmaceuticals, these machines offer precision, control, and efficiency that enhance production processes and product quality. As we continue to explore the potential of double screw extruder machines, we can expect to see even more innovative and groundbreaking applications in diverse fields.

The Impact of Double Screw Extruder Machines on Manufacturing Efficiency

In the realm of industrial food machinery, the double screw extruder machine has emerged as a game-changer, revolutionizing manufacturing processes and significantly enhancing efficiency.

Enhanced Production Speed and Capacity | One of the most immediate benefits of double screw extruder machines is their ability to increase production speed and capacity. Unlike traditional single-screw extruders, double screw extruder machines utilize two intermeshing screws that work in tandem to provide more efficient mixing and extrusion of food materials. This design allows for higher throughput and shorter cycle times, enabling manufacturers to produce larger quantities of food products in less time. Moreover, the precision and control offered by double screw extruder machines enable manufacturers to maintain consistent product quality, even as production volumes increase. This is particularly important in the food industry, where consumer demands for high-quality, consistent products are constantly rising. |

Reduced Waste and Material Loss | Another significant impact of double screw extruder machines on manufacturing efficiency is their ability to reduce waste and material loss. The intermeshing screws of these machines provide excellent mixing and kneading action, ensuring that all ingredients are evenly distributed and fully utilized. This minimizes the risk of over-processing or under-processing, which can lead to material waste and product defects. Furthermore, double screw extruder machines are designed to handle a wide range of food materials, including those with high moisture content or sticky textures. This versatility allows manufacturers to process a wider variety of ingredients without compromising product quality or increasing waste. |

Improved Product Quality and Consistency | In addition to enhancing production speed and reducing waste, double screw extruder machines also play a crucial role in improving product quality and consistency. The precision and control offered by these machines enable manufacturers to achieve tight tolerances in product shape, size, and texture. This is particularly important in the production of snacks, breakfast cereals, and other food products where consistent product appearance and texture are critical to consumer satisfaction. Moreover, double screw extruder machines can be equipped with various dies and shaping tools to create a wide range of product shapes and sizes. This flexibility allows manufacturers to quickly adapt to changing consumer demands and market trends, ensuring that their products remain competitive in the marketplace. |

Challenges and Future Trends in Double Screw Extruder Machine Technology

While these machines have revolutionized manufacturing processes and significantly enhanced efficiency, they also present a number of challenges that must be addressed to ensure continued innovation and growth. In this article, I will discuss the challenges currently facing double screw extruder machine technology and explore the future trends that are likely to shape its development.

1.Challenges in Double Screw Extruder Machine Technology

One of the primary challenges in double screw extruder machine technology is the need for constant innovation and improvement. As consumer demands for high-quality, consistent food products continue to rise, manufacturers must invest in research and development to ensure that their machines can meet these demands. This requires a deep understanding of material science, process engineering, and automation technology, as well as a commitment to continuous improvement and innovation.

Another challenge is the complexity of double screw extruder machines. These machines are highly specialized and require a high level of precision and control to operate effectively. As a result, they can be difficult to maintain and repair, and require a skilled workforce to operate and manage. Manufacturers must invest in training and development programs to ensure that their workforce has the necessary skills and knowledge to operate these machines effectively.

Finally, the cost of double screw extruder machines can be a significant barrier to entry for smaller manufacturers. These machines are often expensive to purchase and maintain, and can require a significant investment in infrastructure and equipment to support their operation. As a result, smaller manufacturers may struggle to compete with larger, more established companies that have the resources to invest in the latest technology.

2.Future Trends in Double Screw Extruder Machine Technology

Despite these challenges, the future of double screw extruder machine technology is bright. One of the key trends that is likely to shape its development is the increasing demand for sustainable and eco-friendly manufacturing processes. Consumers are increasingly concerned about the environmental impact of their food choices, and manufacturers are responding by investing in technology that reduces waste, minimizes energy consumption, and uses sustainable materials.

Double screw extruder machines are well-suited to this trend, as they offer a high degree of precision and control over the manufacturing process. This allows manufacturers to optimize their production processes to minimize waste and energy consumption, while still producing high-quality food products.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/