Everything You Need To Know About Puff Snacks Making Machine

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/

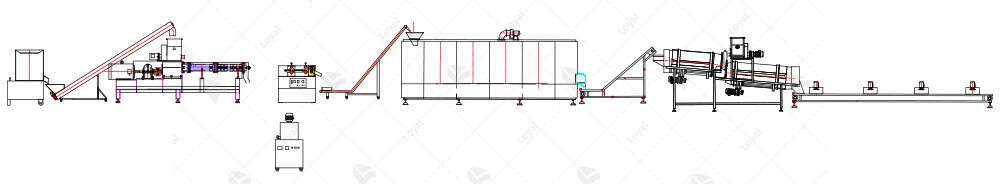

Introduction to Puff Snacks Making Machine

A puff snacks making machine is a specialized piece of food processing equipment designed to transform raw ingredients like corn, rice, or potato flour into lightweight, crispy puffed snacks through extrusion and high-temperature expansion. These machines have become indispensable in the modern food industry, enabling mass production of beloved snacks such as cheese puffs, corn curls, and rice cakes. Their significance lies in their ability to streamline production, ensure consistency, and cater to evolving consumer demands for convenient, shelf-stable snacks. From small-scale startups to multinational food corporations, the versatility of these machines allows manufacturers to experiment with flavors, shapes, and textures while maintaining operational efficiency. Technological advancements, such as precision temperature control and AI-driven quality monitoring, have further elevated their role in driving innovation within the competitive snack market.

How Puff Snacks Making Machines Work

The operational mechanism of a puff snacks making machine is a blend of precision engineering and food science, designed to transform raw ingredients into lightweight, crispy snacks through controlled thermal and mechanical processes. Here’s a detailed breakdown:

Step-by-Step Production Process

Raw Material Preparation:The process begins with mixing starch-rich ingredients like corn, rice, or wheat flour with water and seasonings. Modern machines often integrate automated feeding systems to ensure consistent ingredient ratios, critical for maintaining product uniformity.

Extrusion & Cooking:The heart of the machine is the extruder, a screw-driven component that forces the dough through a specially shaped die under high pressure and temperature (typically 120–180°C). This step cooks the starch, creating a gelatinized structure that expands when pressure is suddenly released.

Puffing:As the extruded dough exits the die, it encounters ambient air, causing rapid moisture evaporation and structural expansion—the “puffing” effect. The die’s design (e.g., circular, star-shaped) directly influences the snack’s final shape and texture.

Drying & Baking:Post-puffing, snacks pass through a multi-zone oven or dryer to remove residual moisture, ensuring crispiness. Advanced machines use infrared or hot-air circulation systems for even baking, minimizing overcooking or undercooking risks.

Flavoring & Packaging:A rotating drum or tumbler applies seasonings, oils, or coatings uniformly. Automated conveyors then transport the finished product to packaging lines, where moisture-resistant bags or containers preserve freshness.

Core Components Driving Efficiency

Extruder: The dual-screw design (common in industrial models) enhances mixing efficiency and reduces wear, ideal for high-output production.

Die & Cutter Assembly: Adjustable dies allow manufacturers to switch between shapes (e.g., balls, rings, or animal figures) without halting operations.

Temperature/Pressure Sensors: Real-time monitoring systems maintain optimal cooking conditions, critical for preventing texture inconsistencies.

Automation Controls: PLC (Programmable Logic Controllers) and touchscreen interfaces enable operators to adjust parameters like speed, temperature, and seasoning dosage, reducing human error.

Key Technical Advancements

Modern puff snacks making machines leverage innovations such as:

Energy-Efficient Motors: Reduce power consumption by up to 30% compared to traditional hydraulic systems.

AI-Driven Quality Control: Cameras and algorithms detect defects (e.g., uneven puffing) in real time, ensuring compliance with food safety standards.

Modular Design: Quick-release components simplify cleaning and maintenance, critical for hygiene in snack production.

By understanding these mechanisms, manufacturers can optimize output, minimize waste, and adapt to evolving consumer preferences for texture, flavor, and nutritional profiles.

Types of Puff Snacks Machines

Type of Machine | Key Features | Advantages | Ideal For | Keywords Integration |

Single-Screw vs. Twin-Screw Extruders | - Single-screw: Cost-effective, simple design | - Single-screw: Low maintenance, suitable for basic puff shapes | - Single-screw: Small-scale producers, startups | - Puff snacks making machine with single/twin-screw technology |

Semi-Automatic vs. Fully Automated Systems | - Semi-automatic: Manual feeding, limited automation | - Semi-automatic: Budget-friendly, requires minimal training | - Semi-automatic: Artisanal snack makers, test kitchens | - Puff snacks making machine automation levels |

Specialized Machines for Specific Snacks | - Corn puff machines: High-temperature expansion | - Corn puff: Crispy, airy textures | - Corn puff: Targeting mass markets | - Puff snacks making machine for corn/rice/cereal snacks |

Portable/Small-Scale Machines | - Compact design, plug-and-play operation | - Affordable entry point for new businesses | - Startups, food truck operators, home-based entrepreneurs | - Puff snacks making machine for small businesses |

Expert Insight:The choice of puff snacks making machine depends on production goals, budget, and market demand. Twin-screw extruders, while pricier, offer unmatched flexibility for experimenting with trends like plant-based or low-fat snacks. Conversely, portable machines democratize access to puff snack production, enabling even microbusinesses to compete in the $XX billion global snack market.

Key Features to Consider When Buying

When investing in a puff snacks making machine, prioritizing technical specifications, operational efficiency, and long-term usability is critical. Below are the core features to evaluate:

Capacity and Production Output

Scalability: Assess whether the machine aligns with your current production needs and future growth. Small-scale machines (10–50 kg/hour) suit startups, while industrial-grade models (100–500 kg/hour) cater to large manufacturers.

Batch vs. Continuous Processing: Continuous systems reduce downtime but require higher initial investment. Batch machines offer flexibility for testing new recipes.

Example: A twin-screw extruder with a 200 kg/hour capacity is ideal for mid-sized factories targeting regional distribution.

Energy Efficiency and Operational Costs

Power Consumption: Look for machines with energy-saving modes or variable frequency drives (VFDs) to optimize electricity use.

Heat Recovery Systems: Advanced models reuse waste heat from ovens, cutting gas/electricity bills by up to 30%.

Cost-Benefit Analysis: A machine with a 15% higher upfront cost but 25% lower energy use may yield ROI within 2 years.

Customization Options

Die Versatility: Machines with interchangeable dies allow production of diverse shapes (stars, rings, balls) without hardware modifications.

Flavor Integration: Built-in flavoring systems enable even coating of seasonings, reducing manual labor and waste.

Gluten-Free/Vegan Adaptability: Ensure the machine’s materials (e.g., stainless steel, food-grade coatings) comply with specialty diet standards.

Safety Standards and Compliance Certifications

Certifications: Prioritize machines with CE (EU), FDA (US), or ISO 22000 certifications to meet global food safety norms.

Operator Safety: Features like emergency stops, automatic shutoffs for overheating, and guarded moving parts minimize workplace risks.

Hygienic Design: Easy-to-clean surfaces and CIP (Clean-In-Place) systems prevent cross-contamination and comply with HACCP guidelines.

Warranty and After-Sales Support

Warranty Coverage: Opt for manufacturers offering 12–24 months of warranty on critical components (e.g., extruder, motor).

Spare Parts Availability: Confirm that replacements for wear-and-tear parts (e.g., screws, barrels) are stocked locally or regionally.

Training Programs: Some suppliers provide free operator training to maximize machine lifespan and efficiency.

By methodically evaluating these features, buyers can balance budget constraints with long-term productivity, ensuring their puff snacks making machine delivers consistent quality and profitability.

Maintenance and Troubleshooting Tips

Proper maintenance and prompt troubleshooting are critical to maximizing the lifespan and efficiency of a puff snacks making machine. Neglecting these aspects can lead to costly downtime, inconsistent product quality, and safety hazards. Below is a structured guide to ensure optimal performance:

Daily Cleaning and Hygiene Protocols

Disassembly and Cleaning: After each production cycle, disassemble removable parts (e.g., dies, conveyors, flavoring drums) and clean them with food-grade sanitizers. Avoid abrasive tools to prevent surface damage.

Heat Element Inspection: Wipe down heating chambers and ovens to prevent residue buildup, which can cause uneven baking or fire risks.

Lubrication: Apply food-safe lubricants to moving parts (e.g., bearings, chains) to reduce friction. Avoid over-lubrication, which may attract debris.

Common Issues and Solutions

Overheating

Cause: Clogged ventilation ducts or malfunctioning cooling fans.

Fix: Clear ducts with compressed air and replace faulty fans immediately. Install temperature sensors to monitor heat levels in real time.

Uneven Extrusion

Cause: Worn-out screws or barrels in the extruder, or inconsistent raw material moisture levels.

Fix: Calibrate the machine’s moisture control system and inspect screws for wear. Replace components if puff thickness varies by >5%.

Flavoring Inconsistencies

Cause: Blocked seasoning nozzles or improper vibration settings on the flavoring drum.

Fix: Clean nozzles with a soft brush and adjust vibration frequency to ensure even coating.

Electrical Failures

Cause: Loose wiring connections or damaged control panels.

Fix: Conduct monthly electrical audits and use thermal cameras to detect hotspots in wiring.

Replacement Parts and Warranty Considerations

Critical Spare Parts: Stockpile items like screws, barrels, and heating elements, as these wear fastest. Choose OEM parts to maintain warranty validity.

Warranty Extensions: Some manufacturers offer extended warranties for machines used in high-temperature environments (e.g., >200°C ovens).

Best Practices for Prolonging Machine Lifespan

Preventive Maintenance Schedule: Implement a 6-monthly inspection by certified technicians to check for alignment issues, hydraulic leaks, or motor vibrations.

Operator Training: Train staff to recognize abnormal sounds, vibrations, or odors—early signs of mechanical stress.

Documentation: Maintain a logbook for maintenance activities, including dates, parts replaced, and performance metrics (e.g., energy consumption post-service).

By adhering to these guidelines, manufacturers can reduce unexpected breakdowns by up to 40% and extend the puff snacks making machine’s operational life by 5–7 years.

Market Trends and Innovations

The global puff snacks making machine market is evolving rapidly, driven by shifting consumer preferences, technological breakthroughs, and sustainability demands. Below are the key trends shaping the industry’s future:

Health-Driven Customization

Clean Label Demand: Manufacturers are adopting machines that support gluten-free, vegan, and low-sugar recipes. Modern extruders now handle alternative flours like quinoa, millet, and lentil, catering to health-conscious markets.

Nutritional Fortification: Advanced systems integrate vitamins, proteins, or fiber during extrusion, enabling “better-for-you” snacks without compromising texture.

AI and IoT Integration

Predictive Maintenance: Sensors monitor machine performance in real time, alerting operators to issues like screw wear or temperature fluctuations before breakdowns occur.

Recipe Optimization: AI algorithms analyze data from extrusion trials to refine pressure, moisture, and cooking time, ensuring consistent puff quality.

Example: A leading manufacturer reduced waste by 18% using AI-driven adjustments to oven temperatures during production runs.

Sustainability Focus

Energy-Efficient Designs: Next-gen machines use 40% less energy via heat recapture systems and hybrid electric-gas ovens.

Biodegradable Packaging Compatibility: Machines now include attachments for compostable film wrapping, aligning with eco-friendly branding.

Circular Economy Practices: Some factories repurpose scraps from puff production into animal feed, minimizing waste.

Emerging Market Opportunities

Asia-Pacific Growth: Rising disposable incomes in India, Southeast Asia, and Africa are fueling demand for affordable, shelf-stable snacks. Compact, low-cost machines dominate these markets.

E-Commerce Impact: Direct-to-consumer brands invest in modular machines for on-demand production, reducing inventory costs.

Automation and Labor Efficiency

Robotic Handling: Collaborative robots (cobots) now manage tasks like die changes and flavoring application, cutting labor costs by up to 30%.

Remote Operation: Cloud-connected machines allow real-time monitoring via smartphones, ideal for multi-site manufacturers.

Regulatory Pressures

Food Safety Modernization Act (FSMA): Compliance requires machines with traceability features, such as lot-code engraving on packaging.

Carbon Tax Impact: European factories are upgrading to electric-powered machines to avoid penalties under stricter emissions laws.

By aligning with these trends, puff snacks making machine manufacturers and users can capitalize on growing health, sustainability, and efficiency demands while maintaining competitiveness in a $15 billion global market.

FAQs About Puff Snacks Making Machines

Q1: How Do I Choose the Right Machine Size for My Business?

Start by evaluating your production goals and operational scale.

Small Businesses/Startups: Opt for compact, semi-automatic machines (10–50 kg/hour) to minimize upfront costs and space requirements.

Mid-Sized Factories: Prioritize machines with 50–200 kg/hour capacity, offering a balance between speed and flexibility for regional markets.

Large Manufacturers: Invest in industrial-grade, fully automated systems (200–500 kg/hour) with built-in quality control sensors.

Pro Tip: Always overshoot your current needs by 20% to accommodate future growth without replacing equipment prematurely.

Q2: Can These Machines Produce Sugar-Free or Vegan Puff Snacks?

Yes, but compatibility depends on material handling and certifications.

Material Flexibility: Stainless steel contact parts and non-stick coatings prevent cross-contamination, critical for allergen-free or vegan recipes.

Certifications: Ensure the machine complies with vegan standards (e.g., Vegan Society certification) and sugar-free labeling regulations.

Example: A machine with a dedicated flavoring system can evenly distribute stevia or plant-based seasonings without clumping.

Q3: What Is the Average ROI for Commercial Puff Snacks Machines?

Return on investment (ROI) varies by machine type and utilization:

Entry-Level Machines: ROI within 12–18 months for businesses operating at 80%+ capacity.

Premium Industrial Models: ROI in 24–36 months, driven by higher output and lower per-unit production costs.

Hidden Costs: Factor in energy bills, maintenance, and operator training when calculating ROI.

Formula: ROI (%) = (Net Profit / Machine Cost) × 100.

Q4: What Training Do Operators Need?

Minimal formal qualifications are required, but structured training is essential:

Supplier Programs: Many manufacturers offer free 1–3 day courses covering safety, cleaning, and troubleshooting.

Digital Resources: Look for machines with user manuals, video tutorials, and 24/7 technical support.

Certification: Operators should earn a basic food safety certification (e.g., HACCP) to handle production lines.

Reference

Here are five authoritative foreign websites related to industrial food machinery, along with their URLs:

1.ThomasNet

Website: https://www.thomasnet.com

2.MachineryTrader

Website: https://www.machinerytrader.com

3.Food Engineering:https://www.foodengineeringmag.com

4.Pack Expo:https://www.packexpo.com

5.DirectIndustry:https://www.directindustry.com