Everything you need to know about microwave dehydrator In 2024

Introduction

Welcome to the ultimate guide to microwave dehydrators in 2024. In this comprehensive guide, we will delve into the intricacies of microwave dehydrators, exploring their working principles, applications, technological advancements, and future outlook. As experts in the field of food processing machinery, we understand the importance of staying abreast of the latest developments in technology to optimize efficiency, enhance product quality, and meet the evolving demands of consumers and industries alike. Let's embark on this journey to unravel everything you need to know about microwave dehydrators in the year 2024.

Working principle of microwave dehydrators

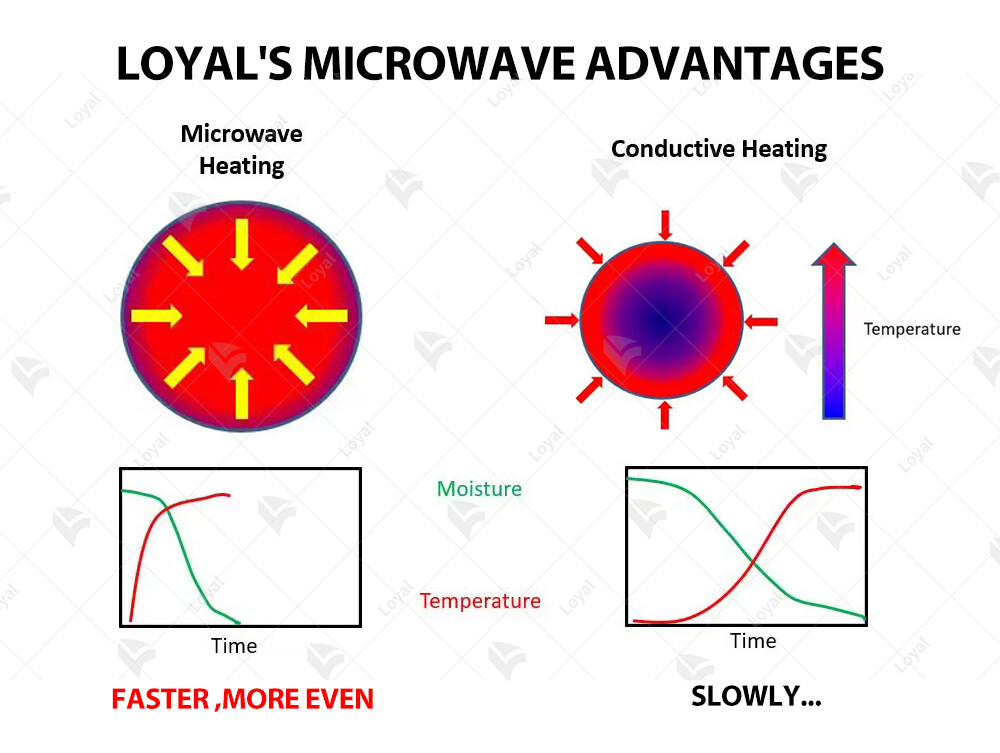

The working principle of microwave dehydrators involves utilizing microwave radiation to remove moisture from food products efficiently and rapidly. When food is placed inside the microwave dehydrator, microwave energy is emitted, causing water molecules within the food to oscillate. This oscillation generates heat, which in turn evaporates the moisture content of the food. Unlike traditional dehydration methods that rely on convection or conduction heating, microwave dehydrators penetrate the food directly, resulting in faster drying times and preserving the nutritional integrity and flavor of the food.

Advantages of Microwave Dehydrators

Advantages of Microwave Dehydrators | Description |

Faster Dehydration Process | Microwave dehydrators utilize electromagnetic waves to rapidly remove moisture from food products. This results in significantly shorter dehydration times compared to conventional methods, allowing for higher throughput and increased productivity. |

Better Preservation of Nutrients | The gentle heating provided by microwave dehydrators helps retain the nutritional content of foods, including vitamins, minerals, and antioxidants. This preserves the natural goodness of the ingredients and ensures that the dehydrated products maintain their nutritional value over time. |

Improved Flavor and Texture | Unlike traditional drying methods that can sometimes lead to flavor loss and texture changes, microwave dehydration preserves the original taste and texture of the food. This results in dehydrated products that are more appealing to consumers and maintain their natural characteristics. |

Energy Efficiency | Microwave dehydrators are often more energy-efficient than conventional drying techniques, as they require shorter processing times and lower temperatures. This can lead to significant cost savings for food manufacturers, especially when drying large quantities of products. |

Enhanced Safety and Hygiene | Microwave dehydrators offer improved safety and hygiene compared to methods that involve prolonged exposure to high temperatures. The rapid heating process helps eliminate harmful microorganisms, reducing the risk of foodborne illnesses and ensuring product safety. |

Versatility in Application | Microwave dehydrators can be used to dry a wide range of food products, including fruits, vegetables, meats, and herbs. They are also suitable for drying delicate items that may be damaged by traditional drying methods, such as flowers or medicinal herbs. |

Space-saving Design | Many microwave dehydrators feature compact and space-saving designs, making them ideal for use in kitchens with limited countertop or storage space. Their smaller footprint allows for easy integration into existing food processing operations without requiring significant modifications. |

Key components of microwave dehydrators

Microwave dehydrators are sophisticated pieces of equipment designed to remove moisture from food products efficiently and effectively. Understanding the key components of these machines is essential for optimizing their performance and ensuring high-quality dehydration results.

Component | Description |

Microwave Generator | The microwave generator is the heart of the dehydrator, producing electromagnetic waves at specific frequencies. |

Magnetron | The magnetron converts electrical energy into microwave radiation, which is emitted into the drying chamber. |

Waveguide | The waveguide directs microwave radiation from the magnetron into the drying chamber, ensuring uniform distribution. |

Drying Chamber | The drying chamber houses the food products to be dehydrated and is designed to allow efficient exposure to microwaves. |

Turntable | The turntable rotates the food products inside the drying chamber, ensuring uniform heating and dehydration. |

Temperature Sensor | Temperature sensors monitor the temperature inside the drying chamber, allowing precise control of the dehydration process. |

Control Panel | The control panel allows operators to set and adjust parameters such as drying time, temperature, and power level. |

Safety Interlocks | Safety interlocks ensure that the dehydrator operates safely by preventing access to the drying chamber when in use. |

Exhaust System | The exhaust system removes moisture and hot air from the drying chamber, maintaining optimal dehydration conditions. |

Each of these components plays a crucial role in the functionality and performance of microwave dehydrators. By understanding how they work together, operators can effectively utilize these machines to achieve efficient and consistent dehydration results.

Comparison and advantages of microwave technology and traditional drying methods

Parameters | Microwave Technology | Traditional Drying Methods |

Heating Mechanism | Utilizes microwave radiation to directly heat and evaporate moisture within the food product. | Relies on convection, conduction, or radiation to transfer heat to the food product, causing moisture evaporation. |

Drying Time | Generally shorter drying times due to the rapid and uniform heating of the entire product. | Often longer drying times, especially for thicker or denser products, due to slower heat transfer rates. |

Energy Efficiency | Typically more energy-efficient as microwave energy is directly absorbed by the food product, minimizing heat loss. | May be less energy-efficient, particularly in large-scale operations, due to heat loss during the drying process. |

Product Quality | Preserves color, flavor, and nutritional value more effectively by minimizing exposure to prolonged high temperatures. | May result in some loss of color, flavor, and nutrients due to extended exposure to heat. |

Control and Automation | Offers precise control over drying parameters such as temperature, humidity, and power levels, often with automated controls. | Control parameters may be less precise and require more manual monitoring and adjustment. |

Space and Footprint | Generally requires less space and infrastructure, making it suitable for both small-scale and large-scale operations. | May require larger drying facilities and infrastructure, particularly for traditional methods such as air or sun drying. |

Environmental Impact | Tends to have a lower environmental impact due to reduced energy consumption and shorter processing times. | May have a higher environmental impact, depending on the energy source used and any associated emissions. |

Types of Microwave Dehydrators

Microwave dehydrators play a pivotal role in the food processing industry, offering rapid and efficient dehydration of various food products. In 2024, several types of microwave dehydrators have emerged, each tailored to specific applications and production needs.

1. Batch Microwave Dehydrators:

Batch microwave dehydrators are designed to process food products in discrete batches. They typically consist of a chamber where the food is placed for dehydration, along with microwave emitters to generate the necessary heat. These dehydrators are suitable for small to medium-scale production environments where flexibility and versatility are key. Batch dehydrators are commonly used for drying fruits, vegetables, herbs, and spices.

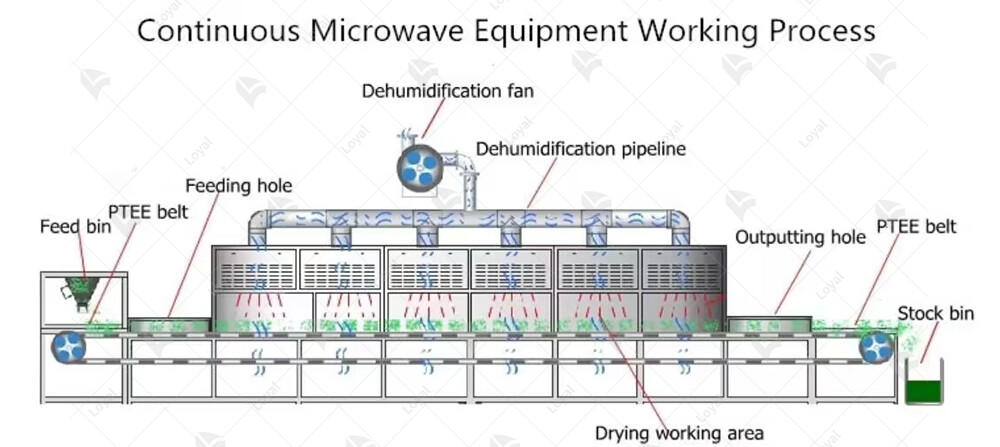

2. Continuous Microwave Dehydrators:

Continuous microwave dehydrators are designed for high-volume production settings, where a continuous flow of food products needs to be processed. Unlike batch dehydrators, continuous dehydrators feature a conveyor belt system that moves the food products through the dehydration chamber at a consistent rate. This allows for a continuous and uniform drying process, making them ideal for large-scale operations. Continuous dehydrators are commonly used in the production of snacks, cereals, and pet foods.

3. Vacuum Microwave Dehydrators:

Vacuum microwave dehydrators combine the benefits of microwave heating with vacuum technology to achieve rapid and efficient dehydration while minimizing product degradation. By reducing the pressure inside the dehydration chamber, vacuum dehydrators lower the boiling point of water, allowing for faster moisture removal at lower temperatures. This preserves the nutritional quality and sensory characteristics of the food products. Vacuum microwave dehydrators are particularly suited for heat-sensitive products such as dairy, meat, and seafood.

4. Hybrid Microwave Dehydrators:

Hybrid microwave dehydrators integrate microwave technology with other drying methods, such as hot air convection or infrared heating. By combining multiple drying techniques, hybrid dehydrators offer enhanced flexibility and control over the drying process, allowing manufacturers to achieve specific texture and quality attributes in their products. These dehydrators are versatile and can be adapted to a wide range of food products, including grains, nuts, and meat snacks.

5. Laboratory-Scale Microwave Dehydrators:

Laboratory-scale microwave dehydrators are compact and specialized units designed for research and development purposes, as well as small-scale production trials. These dehydrators allow food scientists and researchers to study the effects of microwave dehydration on different food materials and optimize drying parameters for specific applications. Laboratory-scale dehydrators are essential tools for product development and process optimization in the food industry.

Technical parameters

| Technical Parameters Of Continuous Microwave Dryer Industrial Microwave Drying Machine | |||||

| Model | Size LWH(Can be customized according to the customer's requirements) | Output power | Dewaterability | Sterilization capacity | Baking and Roasting capacity (Depends on different raw material) |

| LY-10KW | 5000mm825mm1750mm | ≥10KW | 10KG/Hour | 100KG/Hour | 30-50KG/Hour |

| LY-20KW | 8000mm825mm1750mm | ≥20KW | 20KG/Hour | 200KG/Hour | 60-100KG/Hour |

| LY-30KW | 8500mm1160mm1750mm | ≥30KW | 30KG/Hour | 300KG/Hour | 90-150 KG/Hour |

| LY-40KW | 10000mm1160mm1750mm | ≥40KW | 40KG/Hour | 40KG/Hour | 120-200KG/Hour |

| LY-50KW | 12500mm1160mm1750mm | ≥50KW | 50KG/Hour | 500KG/Hour | 150-250KG/Hour |

| LY-60KW | 13500mm1450mm1750mm | ≥60KW | 60KG/Hour | 600KG/Hour | 180-300KG/Hour |

| LY-70KW | 13500mm1500mm1750mm | ≥70KW | 70KG/Hour | 700KG/Hour | 210-350KG/Hour |

| LY-80KW | 13500mm1650mm1750mm | ≥80KW | 80KG/Hour | 800KG/Hour | 240-400KG/Hour |

| LY-100KW | 16800mm1650mm1750mm | ≥100KW | 100KG/Hour | 1000KG/Hour | 300-500KG/Hour |

| LY-150KW | 22400mm1850mm1750mm | ≥150KW | 150KG/Hour | 1500KG/Hour | 450-750KG/Hour |

| LY-200KW | 27000mm1850mm1750mm | ≥250KW | 250KG/Hour | 2500KG/Hour | 750-1250/Hour |

| LY-300KW | 32000mm1850mm1750mm | ≥300KW | 300KG/Hour | 3000KG/Hour | 900-1500KG/Hour |

| Power Supply | 380V±10% 50Hz±1% Three-Phase Five-Wire | ||||

| Microwave Output Frequency | 2450±50Mhz | ||||

| Microwave Input Apparent Power | ≤168Kva | ||||

| Microwave Output Power | ≥120Kw | ||||

| Microwave Power Adjustment Range | 0-30Kw(Adjustable) | ||||

| Ambient Temperature | -5-40°C | ||||

| Relative Humidity | ≤80%, Surrounding Environment:No Corrosive Gas, Conductive Dust And Explosive Gas | ||||

| Transmission Speed | 0-10m/Min(Adjustable) | ||||

Precautions for the Selection and Implementation of Microwave Dehydrators

When it comes to selecting and implementing microwave dehydrators in your food processing operations, there are several key precautions to consider. Microwave dehydrators offer numerous benefits, including faster drying times, improved product quality, and energy efficiency. However, to ensure optimal performance and safety, it's essential to follow these precautions:

1. Capacity and Scalability:

Before selecting a microwave dehydrator, carefully assess your production needs and the scalability of the equipment. Ensure that the dehydrator has sufficient capacity to handle your current production volume, as well as any anticipated growth in the future. Overloading the dehydrator can lead to uneven drying and reduced efficiency.

2. Power Requirements:

Microwave dehydrators require significant power to operate efficiently. Before installation, verify that your facility's electrical infrastructure can support the power requirements of the dehydrator. Inadequate power supply can result in suboptimal performance and increased operating costs.

3. Product Compatibility:

Consider the characteristics of the products you intend to dehydrate and ensure that the microwave dehydrator is compatible with them. Some products may require specific drying parameters or equipment features to achieve the desired results. Conduct thorough testing to verify the compatibility and performance of the dehydrator with your products.

4. Maintenance and Calibration:

Regular maintenance and calibration are essential to ensure the continued performance and accuracy of the microwave dehydrator. Follow the manufacturer's guidelines for routine maintenance tasks, such as cleaning, lubrication, and calibration of sensors and controls. Failure to maintain the dehydrator properly can result in substandard drying and potential equipment failures.

5. Safety Precautions:

Microwave dehydrators utilize high-power microwave radiation, which can pose safety risks if not handled properly. Train operators on the safe operation of the equipment and provide appropriate personal protective equipment (PPE) as needed. Implement safety protocols to minimize the risk of accidents or injuries during operation.

6. Regulatory Compliance:

Ensure that your microwave dehydrator complies with relevant regulatory standards and guidelines for food processing equipment. This includes adherence to sanitation, electrical safety, and electromagnetic compatibility (EMC) regulations. Failure to comply with regulatory requirements can result in fines, product recalls, or legal liabilities.

7. Testing and Validation:

Before full-scale implementation, conduct thorough testing and validation of the microwave dehydrator to ensure its performance meets your requirements. Test the dehydrator under various operating conditions and validate the drying results against quality standards. Make any necessary adjustments or optimizations based on the testing outcomes.

In conclusion, selecting and implementing a microwave dehydrator requires careful consideration of various factors to ensure optimal performance, safety, and regulatory compliance. By following these precautions and guidelines, you can maximize the benefits of microwave dehydration technology in your food processing operations while minimizing risks and challenges.

Challenges and limitations of microwave dehydrators

1. Uneven Dehydration:

One of the primary challenges associated with microwave dehydrators is the potential for uneven dehydration. Due to variations in the distribution of moisture within food products, certain areas may dehydrate more rapidly than others. This can result in inconsistencies in texture and moisture content, affecting the overall quality of the dehydrated product.

2. Limited Capacity:

Another limitation of microwave dehydrators is their limited capacity compared to conventional dehydration methods. While they offer rapid dehydration times, their processing capacity may be insufficient for large-scale production or processing bulky food items. Manufacturers and operators must carefully consider the throughput requirements and scalability of microwave dehydrators for their specific applications.

3. Product Characteristics and Compatibility:

The effectiveness of microwave dehydrators is highly dependent on the characteristics of the food products being processed. Certain products, such as those with high sugar or fat content, may be more prone to overheating or uneven dehydration. Additionally, the size, shape, and moisture content of food items can impact their compatibility with microwave dehydrators, necessitating careful selection and optimization of processing parameters.

4. Energy Consumption:

While microwave dehydrators offer significant energy savings compared to traditional dehydration methods, they still require substantial power to operate. High energy consumption can lead to increased operating costs, especially for continuous or large-scale dehydration operations. Manufacturers must consider the energy efficiency of microwave dehydrators and implement strategies to optimize their use and minimize energy consumption.

5. Maintenance and Safety:

Maintaining and operating microwave dehydrators requires specialized training and expertise to ensure optimal performance and safety. Regular maintenance of components such as magnetrons, waveguides, and seals is essential to prevent downtime and ensure consistent operation. Additionally, operators must adhere to safety protocols to minimize the risk of accidents or injuries associated with high-power microwave radiation.

References

The following are five authoritative foreign literature websites in the field of industrial microwaves:

1. IEEE Xplore Digital Library

Website: [https://ieeexplore.ieee.org/]

2.ScienceDirect

Website: [https://www.sciencedirect.com/]

3. SpringerLink

Website: [https://link.springer.com/]

4. Wiley Online Library

Website: [https://onlinelibrary.wiley.com/]

5. PubMed

Website: [https://pubmed.ncbi.nlm.nih.gov/]