Everything you Need to Know About Japanese Style Panko Bread Crumb Making Machine

Introduction to Panko Bread Crumb Machines

Panko bread crumbs are a staple in Japanese cuisine, known for their light, crispy texture that enhances the crunchiness of fried foods. The production of these breadcrumbs requires specialized machinery designed for high-volume manufacturing. Japanese Style Panko Bread Crumb Making Machines are engineered to meet this demand efficiently and consistently.

These machines are equipped with advanced features tailored for producing high-quality panko crumbs at scale. They typically include a series of processing stages that begin with the preparation of bread dough, followed by precise cutting and shaping mechanisms to achieve the distinctive flaky texture of panko crumbs.

Each stage in the process is meticulously designed to optimize production output while maintaining the desired texture and quality of the breadcrumbs. This ensures that manufacturers can meet the rigorous standards of consistency and uniformity required in commercial food production.

In summary, Japanese Style Panko Bread Crumb Making Machines represent a pinnacle of technological innovation in the realm of industrial food machinery. They combine precision engineering with robust manufacturing capabilities to deliver high production volumes of crispy panko breadcrumbs that are essential for enhancing the texture and flavor of various culinary dishes.

History and Evolution of Panko Bread Crumbs

Panko bread crumbs have a rich history rooted in Japanese culinary tradition. Originating in the late 19th century, panko was introduced as a way to adapt Western bread crumbs to Japanese cuisine, offering a lighter, crispier texture ideal for traditional dishes like tonkatsu and tempura. Initially handmade, the process involved manually grinding bread into coarse flakes, which were then baked to achieve the characteristic lightness and crunch.

Over time, the demand for panko grew both domestically and internationally, leading to advancements in production methods. By the mid-20th century, industrial food machinery began to streamline panko production, incorporating automated processes to ensure consistency and efficiency. This evolution marked a significant shift from artisanal methods to high-production capabilities, meeting the expanding global appetite for Japanese culinary staples.

Today, the Japanese style panko bread crumb making machine exemplifies precision engineering tailored to culinary needs. These machines are designed to handle large-scale production without compromising on the delicate texture and superior crispiness that define authentic panko. Innovations in machine technology continue to refine the production process, enhancing quality control and meeting the stringent standards of modern food processing industries.

In conclusion, the evolution of panko bread crumbs reflects a blend of tradition and technological innovation. From humble beginnings in Japanese kitchens to advanced industrial systems, the journey underscores the adaptability of food machinery in meeting the evolving demands of global cuisine.

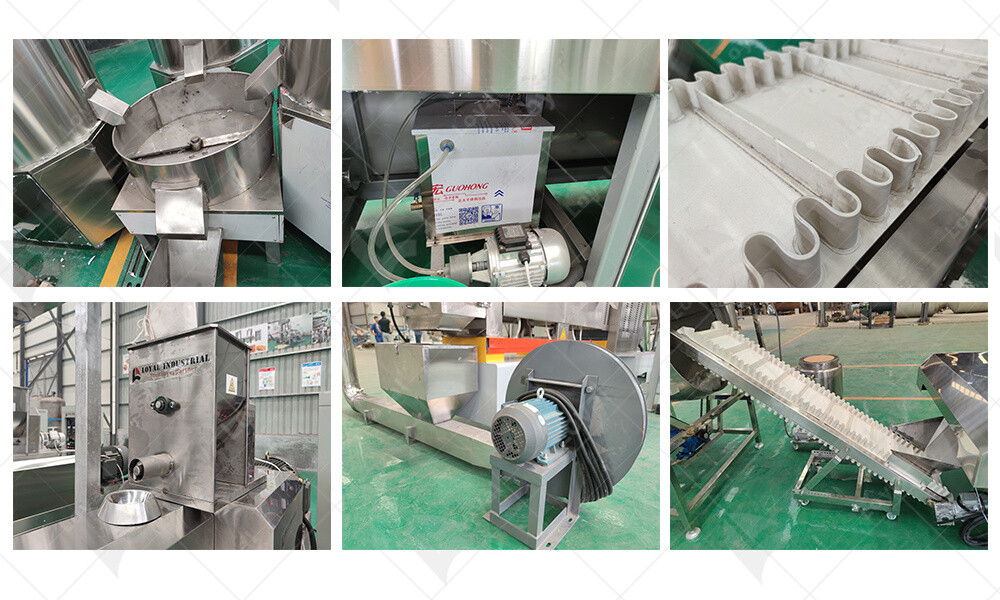

Key Components of Japanese Style Machines

High Production Crispy Panko Breadcrumb Production hinges on several critical components that define the efficiency and reliability of these machines:

Blade Mechanism: At the core of every Panko breadcrumb machine lies its cutting-edge blade mechanism. These machines are equipped with precision-engineered blades that slice bread into uniformly-sized crumbs. The blades are crafted to handle substantial volumes of bread effortlessly, ensuring a consistent product output without compromising on quality.

Drying System: The hallmark of Panko breadcrumbs is their crispy texture, achieved through meticulous drying processes. Japanese machines integrate advanced drying technologies that regulate moisture levels precisely. This meticulous control ensures that the breadcrumbs attain the desired texture, meeting the exacting standards of chefs and consumers alike.

Control Panel: Modern Japanese Panko breadcrumb machines feature intuitive control panels. These panels empower operators to adjust critical parameters such as cutting speed, drying temperature, and production output with precision. Such user-friendly interfaces streamline operations, allowing for seamless adjustments to optimize production efficiency and product quality.

Safety Features: Safety is paramount in industrial food machinery. Japanese Panko breadcrumb machines are equipped with comprehensive safety features, including emergency stop mechanisms, protective covers, and automated shutdown protocols. These features not only safeguard operators but also uphold the integrity of the production process, ensuring uninterrupted operation and product consistency.

Benefits of Using Panko Bread Crumb Machines

Investing in Japanese style Panko breadcrumb making machines offers a multitude of advantages for food manufacturers:

Enhanced Production Capacity: These machines are engineered for High Production Crispy Panko Breadcrumb Production, capable of meeting high-volume demands with efficiency and reliability. Manufacturers benefit from increased output rates, thereby enhancing supply chain dynamics and market competitiveness.

Cost Efficiency: While initial investment costs may be higher, Japanese machines offer substantial long-term cost efficiency. Their durable construction and dependable performance minimize downtime and maintenance expenses, translating into significant operational savings over time. Moreover, efficient resource utilization contributes to sustainable production practices, aligning with global environmental standards.

Quality Assurance: Consistency is pivotal in the food industry. Japanese Panko breadcrumb machines uphold stringent quality control measures, ensuring uniformity in breadcrumb size, texture, and moisture content. This meticulous attention to detail guarantees that each batch of breadcrumbs meets exacting specifications, thereby fortifying brand reputation and consumer trust.

Versatility and Innovation: Beyond traditional Panko breadcrumbs, these machines facilitate versatility in product development. Manufacturers can explore diverse bread types, flavors, and formulations, enabling culinary innovation and market diversification. This adaptability empowers businesses to cater to evolving consumer preferences while maintaining operational flexibility and efficiency.

Operational Processes and Efficiency

The operational processes of High Production Crispy Panko Breadcrumb Production machines are optimized for efficiency and output quality. Typically, these machines begin with the mixing stage, where ingredients are precisely combined to achieve the desired texture and flavor profile of panko breadcrumbs. This initial stage emphasizes the importance of quality control, ensuring that each batch meets stringent standards before advancing to the crumbing process.

During crumbing, the dough is transformed into delicate flakes through a meticulously controlled process. This stage is crucial as it determines the final texture and consistency of the breadcrumbs, a hallmark of Japanese-style panko. The baking or drying process follows, where the flakes are carefully dried to achieve the characteristic light and airy texture that distinguishes panko breadcrumbs from traditional styles.

Efficiency in High Production Crispy Panko Breadcrumb Production machines is further enhanced by advanced automation and control systems. Modern machines incorporate computerized controls that monitor and adjust parameters such as temperature, moisture content, and processing times in real-time. This technological integration not only ensures consistent quality but also minimizes production downtime, thereby maximizing overall operational efficiency.

In conclusion, the High Production Crispy Panko Breadcrumb Production machine represents a pinnacle of innovation in the realm of food production machinery. Its ability to combine precision, efficiency, and quality control makes it indispensable in manufacturing Japanese-style panko breadcrumbs. Whether through batch-processing or continuous-flow systems, these machines cater to diverse production needs while upholding the distinctive characteristics that define panko breadcrumbs in culinary applications.

Types of Panko Bread Crumb Machines Available

When considering a High Production Crispy Panko Breadcrumb Production machine, it's essential to understand the diverse types available to cater to various production needs in the food industry.

Continuous Production Systems: These machines are designed for high-volume production environments where efficiency and output consistency are paramount. They operate continuously, feeding dough through a series of rollers and cutters to create uniform panko breadcrumbs. This type is favored by large-scale commercial bakeries and food manufacturers due to its ability to handle large batches seamlessly.

Batch Production Systems: Ideal for smaller-scale operations or specialized production runs, batch systems process dough in controlled batches. They offer flexibility in production scheduling and are capable of producing high-quality panko breadcrumbs with precise control over dough thickness and cutting parameters. This type suits artisanal bakeries and facilities with diverse product lines requiring tailored production capabilities.

Fully Automated Systems: Incorporating advanced robotics and computerized controls, fully automated systems minimize human intervention while maximizing throughput and product consistency. These machines feature integrated sensors for real-time monitoring of dough quality and breadcrumb characteristics, ensuring uniformity in every batch. They are suitable for high-demand production settings where efficiency and quality are non-negotiable.

Semi-Automated Systems: Combining the benefits of manual operation with automated processes, semi-automated systems offer operators greater control over production parameters. They are adaptable to varying production volumes and product specifications, making them versatile for both small and medium-sized enterprises in the food industry. Operators can adjust settings for dough handling and processing while benefiting from automated cutting and toasting functionalities.

Each type of panko breadcrumb machine addresses specific production requirements, ranging from high-volume commercial production to niche market demands, ensuring flexibility and efficiency in modern food manufacturing processes.

Applications in Food Industry

The versatility of High Production Crispy Panko Breadcrumb Production machines extends across various applications within the food industry, enhancing product quality and operational efficiency.

Bakery and Confectionery: In bakery operations, panko breadcrumbs are used as crispy coatings for fried foods like chicken katsu and shrimp tempura. Panko machines enable bakeries to produce large quantities of uniform breadcrumbs that enhance the texture and taste of baked goods and desserts.

Food Service and Catering: Catering services and restaurants rely on panko breadcrumbs to create crunchy coatings for a variety of dishes, from vegetable fritters to fish fillets. Panko machines ensure consistent breadcrumb quality, allowing food service establishments to maintain high standards of food preparation and presentation.

Frozen Food Manufacturing: Frozen food manufacturers utilize panko breadcrumbs to add texture and flavor to frozen appetizers, seafood products, and prepared meals. The efficiency of panko machines in producing large volumes of breadcrumbs supports streamlined production processes in frozen food manufacturing facilities.

Snack and Convenience Foods: Panko breadcrumbs are increasingly used in snack manufacturing to create innovative products such as breaded snack bars and coated nuts. Panko machines play a critical role in meeting the demand for crispy, flavorful snacks with consistent texture and appearance.

Innovations in Japanese Panko Bread Crumb Technology

In recent years, the technology behind High Production Crispy Panko Breadcrumb Production has seen significant advancements. One major innovation is the integration of IoT (Internet of Things) technology. IoT-enabled machines allow operators to monitor and control production parameters remotely, ensuring optimal performance and minimizing downtime. This connectivity also facilitates predictive maintenance, reducing unexpected failures and extending the lifespan of the equipment.

Another notable innovation is the development of advanced cutting and shaping mechanisms. Traditional panko breadcrumb production often involved manual cutting, which was labor-intensive and inconsistent. Modern machines now feature high-precision cutting tools that produce uniform breadcrumbs with consistent texture and size. These tools are made from durable materials that maintain sharpness and reduce wear, contributing to the efficiency of High Production Crispy Panko Breadcrumb Production.

Energy efficiency is also a key focus in the latest panko breadcrumb machines. Manufacturers are now incorporating energy-saving technologies such as variable frequency drives (VFDs) and high-efficiency motors. These innovations not only reduce energy consumption but also enhance the machine's overall performance. By optimizing energy use, production facilities can lower their operational costs while maintaining high output levels.

Additionally, the use of automation and robotics has revolutionized High Production Crispy Panko Breadcrumb Production. Automated systems can handle everything from dough mixing to breadcrumb drying and packaging. This level of automation minimizes human intervention, reduces the risk of contamination, and ensures consistent product quality. Advanced sensors and control systems further enhance the accuracy and reliability of these automated processes, making them indispensable in modern production lines.

Future Trends and Developments

Looking ahead, the future of High Production Crispy Panko Breadcrumb Production is poised to be shaped by several emerging trends and developments. One such trend is the increasing demand for customization and flexibility in production. Consumers are seeking more diverse breadcrumb textures and flavors, prompting manufacturers to develop machines that can easily adjust to different production parameters. This flexibility allows for the creation of unique panko products that cater to specific market needs.

Sustainability is another critical area driving future developments in panko breadcrumb technology. There is a growing emphasis on reducing the environmental impact of food production. Innovations such as eco-friendly materials for machine construction, energy-efficient processes, and waste reduction techniques are becoming more prevalent. Manufacturers are also exploring ways to recycle and reuse by-products from the breadcrumb production process, aligning with global sustainability goals.

The incorporation of artificial intelligence (AI) and machine learning is expected to further transform High Production Crispy Panko Breadcrumb Production. AI algorithms can analyze vast amounts of production data to optimize processes, predict maintenance needs, and improve product quality. Machine learning can also enable adaptive control systems that automatically adjust production parameters in real-time, ensuring optimal performance and reducing variability.

Finally, advancements in material science are likely to lead to the development of more durable and efficient machine components. New materials with superior properties such as increased wear resistance, higher thermal stability, and improved hygienic qualities will enhance the longevity and performance of panko breadcrumb machines. These innovations will not only improve production efficiency but also ensure compliance with stringent food safety standards.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com