Everything you need to know about food machinery In 2024

Introduction to Food Machinery

Welcome to the comprehensive guide on food machinery in 2024. In this introduction, we will delve into the essential aspects of food machinery, exploring its significance, advancements, and applications in the industrial landscape

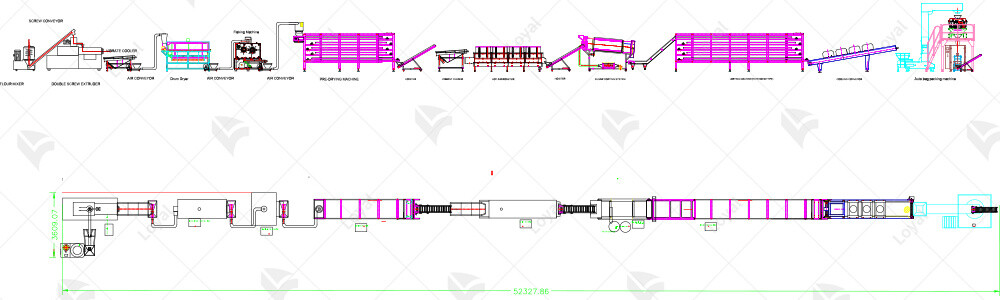

Food machinery, a pivotal component of the food processing industry, encompasses a diverse range of equipment designed to facilitate the production, packaging, and preservation of food products on a large scale. From mixing and grinding to cooking and packaging, these specialized machines play a crucial role in ensuring efficiency, consistency, and safety throughout the food manufacturing process.

Types of Food Machinery

1. Processing Equipment: Processing is the heart of food production, and modern food machinery excels in this domain. These machines encompass a wide array of equipment tailored for different stages of processing. From sorting and washing to slicing and dicing, each process demands specialized machinery for optimal results. For instance, advanced sorting machines utilize cutting-edge technology to ensure precise sorting based on size, color, and quality, enhancing overall efficiency in food processing plants.

2. Packaging Machinery: Packaging plays a crucial role in preserving food quality and extending its shelf life. In 2024, packaging food machinery has evolved to meet the growing demand for convenience and sustainability. From automated filling and sealing machines to innovative packaging designs, the focus is on minimizing waste while maintaining product integrity. Snack machines, for instance, are equipped with advanced sealing mechanisms to ensure airtight packaging, preserving the freshness of snacks for longer durations.

3. Quality Control Systems: Ensuring the highest standards of food safety and quality is non-negotiable in the food industry. This is where food machinery designed for quality control comes into play. These systems employ cutting-edge technologies such as sensors and AI to detect contaminants, irregularities, and defects in real-time, mitigating risks and upholding product quality. With stricter regulations and increasing consumer awareness, investing in quality control food machinery has become imperative for manufacturers to safeguard their reputation and brand image.

4. Automation Solutions: In an era dominated by Industry 4.0, automation has emerged as a game-changer in food production. Automation solutions in food machinery encompass a wide range of applications, from robotic arms handling ingredients to fully automated assembly lines. These technologies not only enhance efficiency and productivity but also minimize human error, leading to consistent quality output. Furthermore, with the integration of IoT and data analytics, manufacturers can gain valuable insights into production processes, enabling proactive maintenance and optimization.

Importance of Food Machinery in the Food Industry

In the dynamic landscape of the food industry, the role of food machinery cannot be overstated. As a seasoned expert in food equipment, I’m here to shed light on why these machines are indispensable in 2024.

Enhanced Efficiency

First and foremost, food machinery revolutionizes efficiency in food production. With advanced snack machines and cutting-edge food equipment, manufacturers can streamline processes, reducing manual labor and time consumption. This enhanced efficiency translates to higher productivity and, ultimately, increased profitability.

Maintaining Quality Standards

Quality control stands as a pillar in the food industry. Here, food machinery plays a pivotal role. These machines are engineered to uphold stringent quality standards consistently. Whether it's snack machines ensuring precise portioning or food equipment guaranteeing optimal processing conditions, maintaining quality is non-negotiable.

Meeting Consumer Demands

Consumer preferences evolve rapidly, driving innovation in the food sector. To meet these demands effectively, manufacturers rely on versatile food machinery. These machines facilitate the rapid development and production of diverse food products, catering to a wide array of tastes and dietary requirements.

Ensuring Food Safety

Safety is paramount in the food industry, and food machinery is at the forefront of ensuring it. With advanced technology and strict adherence to hygiene standards, these machines minimize the risk of contamination and ensure the safety of the final product. From ingredient handling to packaging, every step is meticulously executed to guarantee food safety.

Progress in Food Machinery Technology

1. Automation Revolutionizing Production Processes

One of the most notable advancements in food machinery is the widespread integration of automation. Food machinery now boasts sophisticated systems capable of autonomously handling various stages of production. This automation not only enhances efficiency but also ensures consistent quality across batches. With the ability to minimize human intervention, manufacturers can achieve higher output rates while reducing labor costs.

2. Enhanced Efficiency with IoT Integration

In 2024, the integration of Internet of Things (IoT) technology has transformed food machinery into interconnected systems capable of real-time monitoring and optimization. Through IoT-enabled sensors and devices, manufacturers can gather valuable data on machine performance, production metrics, and product quality. This data-driven approach allows for predictive maintenance, minimizing downtime, and maximizing operational efficiency. Furthermore, IoT integration enables remote monitoring and control, empowering manufacturers to oversee production processes from anywhere in the world.

3. Sustainability Initiatives Driving Innovation

The pursuit of sustainability has spurred innovation in food machinery design and operation. Manufacturers are increasingly prioritizing eco-friendly solutions to minimize resource consumption and waste generation. From energy-efficient processing equipment to recyclable packaging solutions, sustainability initiatives are reshaping the food machinery landscape. Moreover, advancements in biodegradable materials and renewable energy sources are furthering the industry's commitment to environmental stewardship.

4. Customization and Flexibility for Diverse Product Lines

Consumer preferences are becoming increasingly diverse, prompting food machinery manufacturers to prioritize customization and flexibility. In 2024, modular equipment designs allow for easy reconfiguration to accommodate various product specifications and production requirements. Whether producing traditional snacks or innovative culinary creations, food machinery can adapt to meet the evolving demands of the market. This versatility not only enhances product offerings but also fosters agility in response to changing consumer trends.

5. Focus on Food Safety and Quality Assurance

Amidst growing concerns regarding food safety, food machinery advancements in 2024 place a strong emphasis on quality assurance measures. From hygienic design principles to advanced sanitation protocols, manufacturers are implementing robust systems to ensure the integrity of food products. Additionally, technological innovations such as automated inspection systems and traceability solutions enable proactive identification and mitigation of potential hazards. By prioritizing food safety, food machinery plays a crucial role in safeguarding public health and consumer trust.

Comparison between LOYAL and AXOR

Feature | LOYAL Company | AXOR Company |

Technological Leadership | Offers the latest food machinery technology | Has extensive experience in the field of food machinery |

Product Diversity | Produces various types of food machinery equipment | Focuses on specific types of food machinery |

Automation Level | Employs highly automated production processes | Primarily utilizes traditional production methods |

Customization | Provides customized solutions to meet customer needs | Product designs are relatively standardized |

Sustainability Initiatives | Emphasizes environmental protection and sustainability, introduces green products | Implements some environmental measures |

After-Sales Service | Offers comprehensive after-sales support and training services | Provides basic after-sales services |

Market Share | Holds a significant share in the market | Holds influence in specific niche markets |

Innovation Capability | Constantly conducts research and development to introduce innovative products | Focuses on steady product improvements |

Customer Reputation | Well-regarded and considered a reliable partner | Highly regarded and seen as a trustworthy brand |

Sustainable solutions

Sustainable Manufacturing Processes

In the wake of heightened environmental awareness, manufacturers are pivoting towards sustainable production methods for food machinery. This entails optimizing energy usage, minimizing waste generation, and adopting eco-friendly materials. By integrating renewable energy sources into manufacturing plants and employing efficient production techniques, the industry is reducing its carbon footprint while enhancing operational efficiency.

Recyclable Materials

A key facet of sustainable food equipment design is the utilization of recyclable materials. In 2024, manufacturers are prioritizing the use of biodegradable plastics, recycled metals, and compostable components in the construction of snack machines and other food processing equipment. This not only mitigates the environmental impact of discarded machinery but also promotes circular economy principles within the industry.

Energy Efficiency

Energy-efficient design is paramount in modern food machinery. Through advancements in technology, such as the integration of smart sensors and automation systems, manufacturers are optimizing energy consumption without compromising performance. From reducing idle power usage to implementing variable-speed drives, these innovations are driving significant energy savings throughout the food processing chain.

Waste Reduction

Minimizing waste generation is a top priority in sustainable food machinery design. By incorporating innovative recycling and waste management systems, manufacturers are streamlining production processes and minimizing the disposal of by-products. Additionally, advancements in packaging technology are enabling the development of eco-friendly packaging solutions, further reducing the environmental footprint of food processing operations.

Challenges and Future Trends in Food Machinery

In 2024, the landscape of food machinery continues to evolve, driven by technological advancements, consumer demands, and regulatory changes. As experts in the field of industrial food equipment, we are keenly aware of the challenges and emerging trends shaping the industry.

Challenges:

1. Automation Integration: One of the primary challenges facing the food machinery industry is the seamless integration of automation technologies. While automation offers increased efficiency and productivity, the complexity of integrating these systems into existing food production lines remains a significant hurdle. Food machinery manufacturers must develop solutions that facilitate smooth automation integration without disrupting ongoing operations.

2. Regulatory Compliance: Regulatory standards governing food safety and hygiene are becoming increasingly stringent. Food equipment manufacturers are tasked with ensuring that their machinery complies with these regulations to guarantee the safety and quality of the produced food. Adhering to standards such as HACCP (Hazard Analysis and Critical Control Points) and GMP (Good Manufacturing Practices) requires continuous innovation and adaptation.

3. Sustainability: With growing environmental concerns, there is a pressing need for sustainable practices within the food industry. This includes snack machines and other food machinery. Manufacturers are under pressure to develop equipment that minimizes energy consumption, reduces waste, and utilizes eco-friendly materials. Achieving sustainability goals while maintaining operational efficiency poses a significant challenge for the industry.

Future Trends:

1. Smart Manufacturing: The future of food machinery lies in smart manufacturing, enabled by technologies such as Internet of Things (IoT) and artificial intelligence (AI). Smart machines equipped with sensors and data analytics capabilities will revolutionize production processes, offering real-time monitoring, predictive maintenance, and optimization of operations. Manufacturers investing in smart technologies will gain a competitive edge in the market.

2. Customization and Flexibility: Consumer preferences are increasingly diverse, driving the demand for customized food products. To meet this demand, food machinery manufacturers are focusing on developing modular and flexible equipment that can adapt to various recipes and production requirements. Customizable production lines allow for rapid product changes and efficient small-batch manufacturing, catering to the evolving market needs.

3. Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are poised to transform the way food machinery is designed, operated, and maintained. These immersive technologies enable engineers to visualize equipment designs in a virtual environment, facilitating faster prototyping and troubleshooting. Additionally, AR-powered maintenance and training programs enhance operational efficiency by providing real-time guidance and troubleshooting solutions to onsite technicians.

Global Market Trends

In 2024, the global market for food machinery is experiencing significant shifts, driven by technological advancements, changing consumer preferences, and sustainability concerns.

Technological Advancements

Food machinery continues to undergo revolutionary transformations, integrating cutting-edge technologies to enhance efficiency, precision, and safety in food production processes. Snack machines equipped with artificial intelligence (AI) and machine learning algorithms are becoming increasingly prevalent, enabling real-time monitoring and optimization of production lines. These intelligent systems not only streamline operations but also minimize waste, thereby aligning with sustainable practices.

Changing Consumer Preferences

Consumer demand for healthier, convenient, and personalized food options is influencing the design and functionality of food machinery. Manufacturers are investing in versatile food equipment capable of producing a diverse range of snacks, catering to dietary restrictions and flavor preferences. Moreover, there's a growing inclination towards compact and modular snack machines, facilitating decentralized production and reducing transportation costs.

Sustainability Concerns

Sustainability emerges as a driving force reshaping the landscape of food machinery. Manufacturers are prioritizing eco-friendly materials and energy-efficient designs to minimize the environmental footprint of production processes. Additionally, there's a surge in demand for food machinery that enables upcycling and waste reduction, aligning with circular economy principles.

Conclusion

In conclusion, the utilization of food machinery and snack machines has revolutionized the food industry, enhancing efficiency, consistency, and product quality. These food equipment innovations cater to the evolving demands of modern consumers for convenient, nutritious, and diverse food options.

Food machinery plays a pivotal role in streamlining food production processes, from initial ingredient processing to final packaging. Advanced technologies such as automated mixing, kneading, and shaping have optimized the manufacturing of various food products, including snacks, baked goods, and ready-to-eat meals.

Moreover, snack machines have emerged as indispensable assets in both commercial and residential settings. These compact yet efficient devices enable convenient access to a wide array of snacks, ranging from traditional favorites to health-conscious alternatives. By incorporating state-of-the-art features such as customizable vending options and cashless payment systems, snack machines cater to diverse consumer preferences while maximizing operational convenience for businesses.

Furthermore, the integration of cutting-edge food equipment has elevated food safety standards across the industry. With automated sanitation protocols and stringent quality control mechanisms, manufacturers can ensure the integrity and hygiene of their products, mitigating the risk of contamination and ensuring compliance with regulatory guidelines.

Overall, the application of food machinery and snack machines underscores the continuous innovation within the food industry. By embracing technological advancements and leveraging automation, businesses can meet consumer demands for convenience, quality, and variety, thereby driving growth and profitability in the dynamic marketplace.

Reference materials

Here are some authoritative foreign websites for industrial food machinery-related literature references, along with their URLs:

1. Food Engineering Magazine

Website: [https://www.foodengineeringmag.com/]

2. Food Processing Magazine

Website: [https://www.foodprocessing.com/]

3. Institute of Food Technologists (IFT)

Website: [https://www.ift.org/]

4. American Society of Agricultural and Biological Engineers (ASABE)

Website: [https://www.asabe.org/]

5. European Federation of Food Science and Technology (EFFoST)

Website: [https://effost.org/]

These websites provide a wide range of information related to industrial food machinery, including the latest industry news, research findings, and technological trends, making them valuable resources for authoritative references and academic research.