Everything you need to know about dry pet food machine In 2024

Introduction

In 2024, the dry pet food machine continues to stand as a cornerstone in the pet food industry, revolutionizing the way we produce nourishing meals for our furry companions. From extruders facilitating the creation of unique shapes and textures to advanced dryers ensuring optimal moisture levels, these machines epitomize precision and efficiency. As demand surges for high-quality pet food products, understanding the intricacies of dry pet food machines becomes paramount for manufacturers striving to meet consumer expectations while staying ahead in this competitive landscape.

Types of Dry Pet Food Machines

Extruders form the cornerstone of dry pet food manufacturing. These robust machines utilize a combination of heat, pressure, and mechanical force to transform raw ingredients into the familiar shapes and textures of dry pet food kibble. By precisely controlling parameters such as temperature, moisture content, and pressure, extruders ensure consistent product quality while maximizing production efficiency.

Dryers play a pivotal role in the final stages of dry pet food production. After the extrusion process, the newly formed kibble contains residual moisture that must be removed to achieve the desired shelf stability and texture. Dryers employ various methods, including hot air convection, to gently and uniformly evaporate moisture from the product, ensuring optimal quality and prolonging shelf life.

Packaging machines represent the final frontier in the journey of dry pet food from production line to consumer shelf. These machines efficiently package the finished product into a variety of formats, including bags, pouches, and containers, while maintaining freshness and integrity. With features such as automated weighing, filling, and sealing, packaging machines ensure accuracy and consistency while meeting the demands of high-volume production.

In summary, the landscape of dry pet food machines encompasses a diverse array of technologies and functionalities, each serving a crucial role in the production process. From extruders that shape and cook the raw ingredients to dryers that remove moisture and packaging machines that prepare the product for distribution, these machines epitomize innovation and efficiency in the pet food industry.

Main features of dry pet food machines

Feature | Description |

Extrusion System | - Extrusionis a key process in dry pet food machinetechnology, involving the cooking, shaping, and drying of ingredients. - The extrudertypically consists of a barrelwith a screw inside that mixes and compresses the ingredients before forcing them through a die to form the desired shape. |

Drying Mechanism | - Efficient drying mechanismsare essential for removing moisture from the pet food mixture to create the desired dry texture. - Dryersin dry pet food machinesemploy various methods such as hot air convection, infrared radiation, or microwave heating to evaporate moisture while maintaining nutritional integrity. |

Control Systems | - Advanced automation and control systemsare integrated into dry pet food machinesto regulate processing parameters such as temperature, pressure, and feed rate. - These systems ensure consistent product quality, optimize energy usage, and minimize downtime through real-time monitoring and adjustment capabilities. |

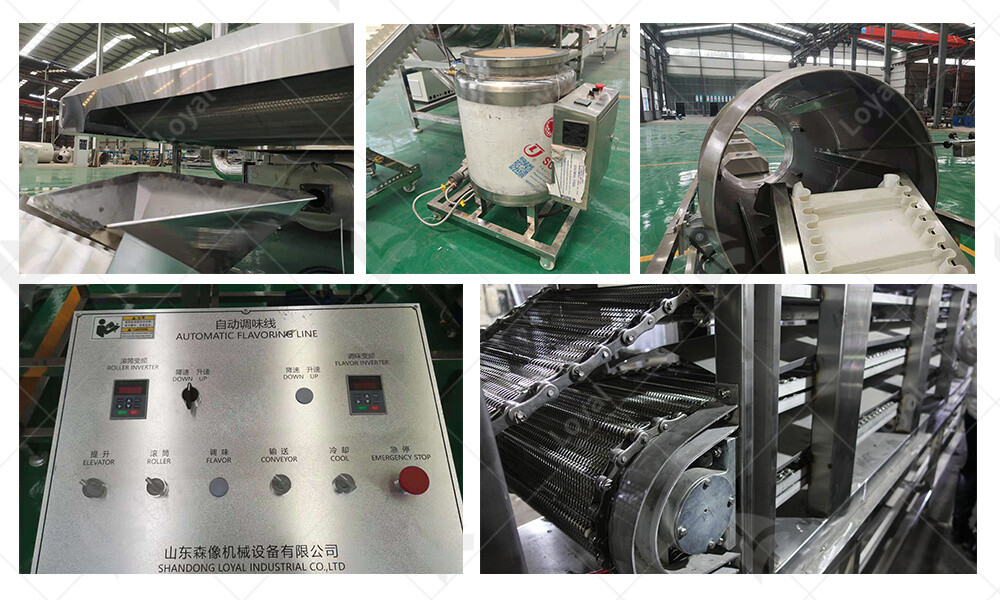

Material Handling | - Material handlingsystems play a crucial role in transporting raw ingredients, additives, and finished products throughout the dry pet food machineprocess. - Conveyors, elevators, and feeders are used to efficiently move materials between processing stages while minimizing cross-contamination and maintaining hygiene standards. |

Sanitation Features | - Hygienic designis paramount in dry pet food machinesto prevent microbial contamination and ensure product safety. - Sanitation featuresinclude easy-to-clean surfaces, removable components, and automated cleaning-in-place (CIP) systems that streamline equipment maintenance and reduce the risk of product recalls. |

Quality Control and Monitoring Systems | - Quality controland monitoring systemsare incorporated into dry pet food machinesto uphold product consistency and compliance with regulatory standards. - Sensors, cameras, and data analytics tools enable real-time inspection of product attributes such as size, shape, color, and nutritional content to identify and rectify deviations from specifications. |

Flexibility and Customization Capabilities | - Modern dry pet food machinesoffer flexiblemanufacturing capabilities to accommodate various recipes, formulations, and packaging formats. - Customization featuresallow producers to adjust ingredient ratios, pellet sizes, and shapes to meet the specific nutritional needs and preferences of different pet species and breeds. |

Energy Efficiency | - Energy efficiencyis a key consideration in dry pet food machinedesign to reduce operating costs and environmental impact. - Equipment features such as insulation, heat recovery, and variable speed drivesoptimize energy usage by minimizing heat loss, recycling waste heat, and adjusting power consumption based on production demand. |

Factors Affecting the Selection of Dry Pet Food Machines

When considering the acquisition of dry pet food machines, several critical factors come into play. These machines are pivotal in the production of high-quality dry pet food, and choosing the right one can significantly impact efficiency, product quality, and overall business success.

One of the foremost considerations when selecting dry pet food machines is production capacity. The machine's ability to meet the demand for dry pet food products is paramount. Assessing current production needs and anticipating future growth is essential to ensure that the chosen machine can handle the workload efficiently.

Another crucial factor is the budget available for acquiring dry pet food machines. While investing in high-quality machinery is important for long-term success, it's also essential to strike a balance between performance and cost-effectiveness. Evaluating the initial investment, as well as ongoing maintenance and operating costs, is vital to making an informed decision.

Ensuring compliance with quality and safety standards is non-negotiable in the pet food industry. Dry pet food machines must meet stringent regulations to guarantee the safety and nutritional integrity of the final products. Factors such as material quality, hygiene features, and adherence to industry standards play a significant role in the selection process.

Comparison between Loyal and NP

Feature | Loyal Company | NP Company |

Product Range | Offers a wide range of industrial food machinery, including dry pet food machines | Specializes in the design and manufacturing of efficient dry pet food machines |

Technological Innovation | Bases on innovative technologies to continuously improve product performance and functionality | Focuses on technological innovation, providing cutting-edge production solutions |

Production Capacity | Possesses large-scale production capabilities to meet various scale demands | Emphasizes production efficiency to ensure continuous supply of high-quality products |

Quality Control | Adheres to strict quality control systems to ensure products meet industry standards | Highlights quality management, ensuring every detail meets the highest standards |

Customization | Provides customized solutions to meet specific customer requirements | Focuses on customer needs, flexibly adjusting product designs to meet market demands |

After-sales Service | Offers comprehensive after-sales service and technical support | Focuses on customer satisfaction, providing timely after-sales service and support |

Sustainability | Committed to sustainability, taking eco-friendly measures to reduce resource consumption | Focuses on environmental protection and sustainability, striving to reduce the environmental impact of production processes |

Technical innovation of dry pet food machines

In 2024, the landscape of dry pet food production is undergoing a significant transformation, largely propelled by dry pet food machines equipped with cutting-edge technical innovations. As an expert in industrial food machinery, it's imperative to delve into the advancements that are shaping this crucial aspect of the pet food industry.

Extruders stand as the cornerstone of dry pet food production lines. These machines have witnessed substantial enhancements, particularly in terms of efficiency and precision. In 2024, extruders are equipped with advanced control systems that enable real-time monitoring and adjustment of processing parameters. This level of automation not only ensures consistent product quality but also optimizes energy consumption, aligning with the industry's sustainability goals.

Accompanying the extruders are state-of-the-art dryers designed to cater specifically to the requirements of pet food manufacturing. Innovations in drying technology have led to the development of systems capable of rapid moisture removal while preserving the nutritional integrity of the ingredients. Through the integration of heat recovery mechanisms, modern dryers maximize energy efficiency, thereby reducing operational costs and environmental impact.

Furthermore, packaging machines have undergone notable advancements to meet the evolving demands of the market. In 2024, packaging solutions for dry pet food products prioritize both functionality and aesthetics. High-speed packaging lines equipped with robotic arms ensure efficient handling and precise filling of bags, pouches, or containers. Moreover, the integration of smart packaging technologies enables real-time tracking of products throughout the supply chain, enhancing traceability and food safety.

One of the most prominent trends in the realm of dry pet food machines is the integration of Internet of Things (IoT) capabilities. By connecting various components of the production line, IoT-enabled machines facilitate seamless communication and data exchange. This enables predictive maintenance, where potential equipment failures are anticipated and addressed proactively, minimizing downtime and maximizing productivity.

Sustainability is another key focus area driving innovation in dry pet food machine technology. Manufacturers are increasingly adopting eco-friendly materials and processes, aiming to reduce waste generation and carbon footprint. From energy-efficient equipment design to the utilization of biodegradable packaging materials, the industry is embracing holistic approaches to sustainability.

In conclusion, the technical innovation observed in dry pet food machines in 2024 is reshaping the landscape of pet food manufacturing. With enhanced efficiency, precision, and sustainability, these machines are not only meeting the current demands of the industry but also paving the way for future advancements. As industrial food machinery experts, it's essential to stay abreast of these innovations to ensure optimal performance and competitiveness in the market.

Post-Maintenance Guide for Dry Pet Food Machine

As a seasoned expert in industrial food machinery, it's imperative to stay updated on the latest advancements, especially in the realm of dry pet food production. In this post-maintenance guide, we'll delve into crucial aspects concerning the upkeep of your dry pet food machine in 2024.

Regular inspection and cleaning are the cornerstones of maintaining optimal functionality and hygiene standards in your dry pet food machine. Components such as the extruder, dryer, and packaging apparatus require meticulous attention. Inspect for any signs of wear, tear, or malfunction, focusing on areas prone to residue buildup or mechanical stress.

Proper lubrication is paramount for ensuring smooth operation and extending the lifespan of critical components. Utilize high-quality lubricants suitable for food-grade machinery and adhere to manufacturer recommendations for application intervals. Additionally, monitor the condition of belts, bearings, and seals, promptly replacing any worn-out parts to prevent operational disruptions.

Maintaining precision and efficiency in the production process necessitates periodic calibration and performance optimization. Verify the accuracy of temperature settings, pressure levels, and extrusion rates, recalibrating as needed to align with desired specifications. Conduct trial runs and performance tests to identify any deviations from optimal parameters and fine-tune accordingly.

Safety should always remain a top priority in industrial settings. Ensure that all personnel operating or maintaining the dry pet food machine are well-versed in safety protocols and emergency procedures. Provide comprehensive training on equipment handling, hazard mitigation, and personal protective equipment usage to mitigate risks and promote a secure working environment.

In the rapidly evolving landscape of food production technology, staying abreast of software updates and technological advancements is indispensable. Keep your dry pet food machine's software systems up-to-date to leverage enhanced functionalities, efficiency improvements, and cybersecurity enhancements. Explore opportunities for technological integration, such as IoT-enabled sensors for real-time monitoring and predictive maintenance capabilities.

As conscientious stewards of the environment, it's incumbent upon industrial food machinery operators to prioritize sustainability initiatives. Evaluate energy consumption patterns and explore opportunities for optimization through equipment upgrades or operational modifications. Implement waste reduction strategies and explore eco-friendly packaging solutions to minimize environmental impact throughout the production process.

Effective post-maintenance practices are essential for maximizing the performance, longevity, and safety of your dry pet food machine in 2024. By adhering to rigorous inspection protocols, embracing technological advancements, and fostering a culture of safety and sustainability, you can uphold the highest standards of quality and efficiency in pet food production. Stay vigilant, stay proactive, and ensure that your operations remain at the forefront of industry excellence.

Conclusion

In conclusion, the advancements in dry pet food machine technology in 2024 signify a pivotal moment in the pet food industry. With the integration of innovative features such as precision control systems, automated cleaning mechanisms, and enhanced material handling capabilities, manufacturers can now achieve higher levels of efficiency and product consistency. These machines not only streamline production processes but also ensure the safety and quality of the final product, meeting the stringent standards of pet food regulations. As we move forward, continuous research and development will drive further enhancements in dry pet food machine design, empowering manufacturers to meet the evolving demands of pet owners worldwide.

References

1.Wenger Manufacturing: https://www.wenger.com

2.Clextral: https://www.clextral.com

3.Bühler Group: https://www.buhlergroup.com

4. Baker Perkins: https://www.bakerperkins.com

5.Andritz Group: https://www.andritz.com