Everything you need to know about dog biscuit maker machine in 2024

Introduction

Welcome to the comprehensive guide on dog biscuit maker machines in 2024. In this guide, we'll delve into the intricacies of dog biscuit maker machines, exploring their significance in the pet food industry and understanding the key factors influencing their usage and purchase.

Dog biscuit maker machines play a crucial role in the production of high-quality, nutritious dog treats. As pet owners increasingly prioritize the health and well-being of their furry companions, the demand for premium-quality dog biscuits continues to rise. In response, manufacturers are continuously innovating and improving dog biscuit maker machines to meet the evolving needs of the market.

In this introduction, we'll provide an overview of what dog biscuit maker machines are, their importance in the pet food industry, and what you can expect to learn from this guide. So, let's dive in and explore everything you need to know about dog biscuit maker machines in 2024.

Types of Dog Biscuit Maker Machines

When it comes to dog biscuit maker machines, there are several types available on the market catering to different needs and preferences. Below is an overview of the main types of dog biscuit maker machines in 2024:

| Type of Machine | Description | Key Features | Suitable for |

| Rotary Mold Dog Biscuit Maker | Rotary mold machines produce dog biscuits by pressing dough into shape using rotating molds. | - High production capacity - Versatile molds for various biscuit shapes and sizes - Automated operation | Large-scale dog biscuit production facilities |

| Wire Cut Dog Biscuit Maker | Wire cut machines slice through dough to create uniform dog biscuits. | - Precise portion control for consistent biscuit size - Adjustable wire cutters for customization - Compact design for smaller production spaces | Small to medium-sized dog biscuit manufacturers |

| Depositor Dog Biscuit Maker | Depositor machines deposit pre-formed dough onto baking trays, allowing for easy customization of biscuit shapes and sizes. | - Flexibility to produce a wide range of biscuit designs - Accurate portion control for uniform biscuits - Quick changeover between different biscuit varieties | Artisanal dog treat makers or businesses offering customized biscuits |

| Extruder Dog Biscuit Maker | Extruder machines use pressure to push dough through a die to create dog biscuits with consistent shapes and sizes. | - High-speed production capabilities - Ability to handle a variety of dough consistencies - Option for multi-flavored or filled biscuits | Large-scale dog biscuit manufacturers with high demand |

Each type of dog biscuit maker machine offers unique advantages and is suitable for different production environments and requirements. By understanding the features and capabilities of each type, dog biscuit manufacturers can choose the machine that best fits their needs and enhances their production efficiency.

Key Components and Technology

When it comes to dog biscuit maker machines, understanding the key components and technology involved is crucial for both manufacturers and consumers. Let's explore the essential elements that make up these machines and the technological advancements shaping their functionality in 2024.

1. Mixing Chamber and Dough Feeding System

At the heart of a dog biscuit maker machine lies the mixing chamber, where ingredients are combined to form the dough. This chamber is equipped with precision mixing blades or paddles to ensure thorough blending of ingredients. The dough feeding system, often consisting of a hopper and conveyor, delivers the mixed dough to the shaping mechanism with precision and consistency.

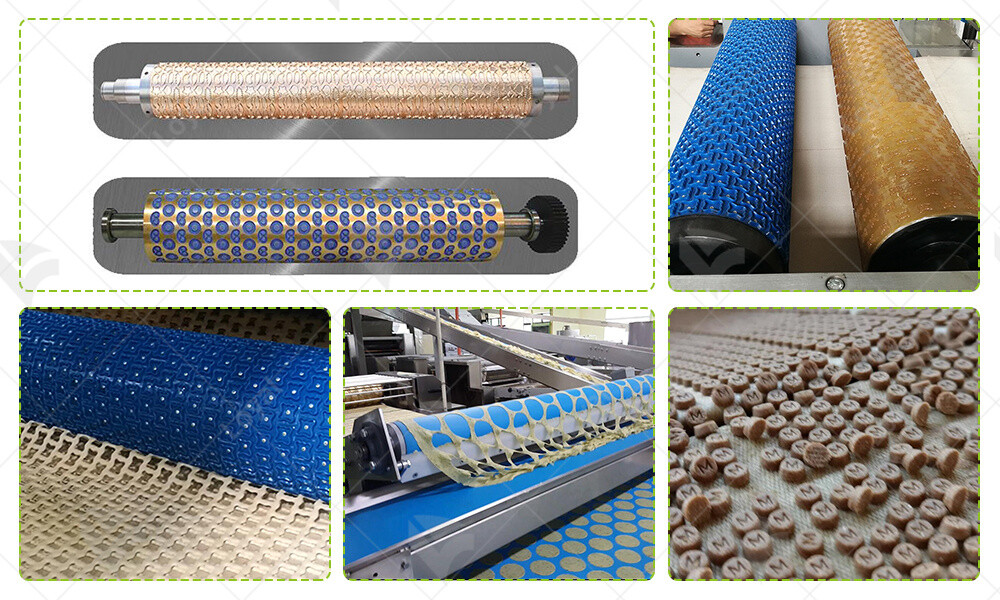

2. Shaping Mechanism

The shaping mechanism of a dog biscuit maker machine is responsible for forming the dough into desired shapes and sizes. Depending on the machine's design, this can involve rotary molds, extrusion dies, or cutting blades. Advanced shaping mechanisms offer versatility, allowing for the production of a wide variety of dog biscuit shapes, from bones to hearts and beyond.

3. Baking Chamber and Heating System

Once the dough is shaped, it enters the baking chamber, where it undergoes the baking process to achieve the desired texture and crunchiness. The baking chamber is equipped with heating elements that provide precise temperature control for consistent baking results. Modern dog biscuit maker machines utilize efficient heating systems that minimize energy consumption while ensuring uniform baking throughout the batch.

4. Cooling and Packaging Stations

After baking, the freshly made dog biscuits proceed to cooling stations, where they are allowed to cool to room temperature before packaging. Cooling systems may include ambient air cooling or specialized cooling tunnels to expedite the process. Once cooled, the biscuits are ready for packaging, which may involve automated packaging stations equipped with weighing scales, bagging machines, and sealing mechanisms.

5. Control Panel and Automation Features

The control panel of a dog biscuit maker machine serves as the command center for operation and monitoring. It allows operators to adjust parameters such as dough consistency, shaping speed, baking temperature, and cooling time. In 2024, advancements in automation technology enable these machines to offer user-friendly interfaces with intuitive controls and real-time monitoring capabilities, enhancing efficiency and productivity.

6. Safety Features and Hygiene Standards

Ensuring product safety and adherence to hygiene standards is paramount in dog biscuit production. Modern machines are equipped with safety features such as emergency stop buttons, safety guards, and interlocking systems to prevent accidents and injuries. Additionally, hygienic design principles are incorporated into machine construction to facilitate thorough cleaning and sanitation, reducing the risk of contamination.

Techniques for Optimizing Production Efficiency and Output

In the domain of dog biscuit maker machines, maximizing production efficiency and output is crucial for meeting the demands of pet food markets. Let's delve into some techniques aimed at achieving these objectives in 2024:

1. Automated Ingredient Handling

One key technique for optimizing production efficiency is the implementation of automated ingredient handling systems. These systems precisely measure and dispense ingredients, reducing the risk of errors and minimizing wastage. By automating this process, manufacturers can streamline production and increase throughput.

2. Advanced Mixing Technology

Investing in dog biscuit maker machines equipped with advanced mixing technology can significantly enhance production efficiency. High-speed mixing systems ensure thorough and uniform blending of ingredients, reducing processing time and improving product consistency. Additionally, adjustable mixing parameters allow for customization according to specific recipe requirements.

3. Continuous Production Lines

Utilizing continuous production lines is another effective technique for maximizing efficiency and output. Unlike batch processing, continuous lines operate seamlessly, with minimal downtime between batches. This results in higher throughput and a more consistent flow of production, ultimately increasing overall output.

4. Multi-Functionality and Flexibility

Opting for dog biscuit maker machines that offer multi-functionality and flexibility can further optimize production efficiency. Machines capable of producing a variety of biscuit shapes, sizes, and textures without the need for extensive reconfiguration allow for greater versatility in meeting diverse market demands. This versatility minimizes changeover time and maximizes machine utilization.

5. Real-Time Monitoring and Control Systems

Implementing real-time monitoring and control systems enables manufacturers to identify and address inefficiencies promptly. These systems provide insights into various aspects of production, including equipment performance, ingredient usage, and product quality. By leveraging data analytics and machine learning algorithms, manufacturers can optimize process parameters to maximize efficiency and output.

6. Predictive Maintenance

Adopting predictive maintenance strategies can help prevent unexpected equipment downtime and prolong machine lifespan. By monitoring machine health indicators in real-time, such as temperature, vibration, and energy consumption, manufacturers can anticipate potential issues and schedule maintenance proactively. This proactive approach minimizes disruptions to production schedules and ensures continuous operation.

Benefits of offering specialty and limited-edition dog treats to attract customers

Benefits | Description |

| Increased Customer Engagement | Offering specialty and limited-edition dog treats can generate excitement and buzz among customers, encouraging them to engage more with your brand. This can lead to increased loyalty and repeat purchases. |

| Market Differentiation | Specialty and limited-edition treats help differentiate your brand from competitors. Unique flavors, ingredients, and designs can attract attention and set your products apart in a crowded market. |

| Higher Perceived Value | Limited-edition and specialty products often carry a higher perceived value, allowing you to command premium prices. Customers are often willing to pay more for exclusive and unique offerings. |

| Seasonal and Thematic Marketing | Introducing seasonal or themed dog treats, such as holiday or special occasion editions, can align with marketing campaigns and capitalize on specific times of the year, boosting sales during these periods. |

| Customer Retention and Loyalty | Regularly introducing new and exciting treats keeps your product line fresh and maintains customer interest. This can enhance customer retention and foster a loyal customer base. |

| Opportunities for Upselling | Specialty and limited-edition treats provide opportunities for upselling and cross-selling. Customers purchasing regular items may be tempted to add these exclusive treats to their order, increasing the average transaction value. |

| Feedback and Market Testing | Limited-edition products can serve as a way to test new flavors or concepts with minimal risk. Customer feedback on these items can inform future product development and adjustments. |

| Enhanced Brand Image | Offering innovative and unique products enhances your brand image as a leader in the pet food industry. It demonstrates a commitment to quality and creativity, appealing to discerning pet owners. |

Health and Nutrition Considerations

When investing in a dog biscuit maker machine in 2024, understanding the health and nutrition considerations is paramount. The demand for high-quality, nutritious pet food is at an all-time high, and a dog biscuit maker machine must be able to meet these standards. Here are the key health and nutrition considerations to keep in mind:

1. Ingredient Quality and Safety

Ensuring the use of high-quality ingredients is crucial for the health of pets. A reliable dog biscuit maker machine should be designed to handle various natural and healthy ingredients such as whole grains, lean meats, and vegetables. It should also be capable of processing ingredients without compromising their nutritional value.

2. Nutritional Balance

The machine should facilitate the production of biscuits that meet the nutritional needs of dogs. This includes balancing proteins, fats, carbohydrates, vitamins, and minerals. Advanced dog biscuit maker machines may offer programmable settings to ensure precise ingredient mixing and baking times, preserving essential nutrients.

3. Allergen Management

With the rise in food allergies among pets, it is important to consider machines that can manage allergen-free production. Machines should be easy to clean and sanitize to prevent cross-contamination of ingredients, particularly when switching between recipes that include common allergens like wheat or soy.

4. Portion Control

Portion control is another critical aspect. The dog biscuit maker machine should offer options for producing biscuits in various sizes and shapes to accommodate different breeds and sizes of dogs. This ensures that pets receive appropriate portion sizes, helping to manage weight and overall health.

5. Additive and Preservative-Free Production

Consumers are increasingly looking for dog treats free from artificial additives and preservatives. The machine should support the production of natural and organic biscuits without the need for harmful chemicals, focusing on maintaining freshness and shelf life through proper baking and storage techniques.

Maintenance and Troubleshooting

Ensuring the optimal performance and longevity of your dog biscuit maker machine requires diligent maintenance and effective troubleshooting. Here are some essential guidelines to help you maintain your equipment and address common issues that may arise.

1. Regular Cleaning

Proper cleaning is crucial for maintaining the efficiency and hygiene of your dog biscuit maker machine.

- Daily Cleaning: After each use, clean all contact surfaces with food-safe cleaning agents. Ensure that no dough or residue is left on the machine, as this can lead to contamination or mechanical issues.

- Deep Cleaning: Perform a thorough cleaning weekly, dismantling parts as recommended by the manufacturer to reach hidden areas. Use brushes and non-abrasive cloths to clean these components without causing damage.

2. Lubrication

Lubricating moving parts of the dog biscuit maker machine is essential to prevent wear and ensure smooth operation.

- Frequency: Follow the manufacturer's guidelines for lubrication frequency. Typically, this should be done monthly or after a set number of operational hours.

- Type of Lubricant: Use food-grade lubricants to avoid contamination of the biscuit dough.

3. Inspection and Replacement of Worn Parts

Regular inspection of your dog biscuit maker machine helps identify parts that need replacement before they fail.

- Routine Checks: Inspect belts, bearings, and cutting blades regularly. Look for signs of wear and tear, such as cracks, fraying, or dull edges.

- Replacement: Replace worn parts immediately to prevent breakdowns and maintain product quality. Always use manufacturer-approved parts to ensure compatibility and safety.

4. Troubleshooting Common Issues

Even with regular maintenance, you may encounter issues with your dog biscuit maker machine. Here are some common problems and their solutions:

- Machine Jamming: If the machine jams, it could be due to dough consistency or debris in the gears. Check the dough mixture for correct consistency and clean the gears thoroughly.

- Inconsistent Biscuit Shapes: This issue often arises from worn or improperly aligned cutting blades. Inspect and replace blades as necessary and ensure they are correctly aligned.

- Uneven Baking: If biscuits bake unevenly, it may be due to an incorrect dough thickness or uneven heating. Verify the settings on your machine and ensure uniform dough distribution.

5. Documentation and Support

Maintaining detailed records of maintenance activities and troubleshooting efforts can help in diagnosing recurring issues and planning preventive measures.

- Logs: Keep a logbook documenting maintenance schedules, parts replacements, and any issues encountered.

- Manufacturer Support: When in doubt, consult the machine’s manual or contact the manufacturer’s support team for guidance.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/