Everything You Need To Know About Corn Snack Machine In 2024

Introduction

In the fast-paced world of snack manufacturing, the corn snack machine stands as a cornerstone of innovation and efficiency. As consumer demand for convenient and flavorful snack options continues to rise, understanding the intricacies of corn snack production technology becomes increasingly essential. In this comprehensive guide, we will explore every aspect of the corn snack machine landscape in 2024, from its evolution to its impact on the industry and its future prospects.

The journey begins with an overview of the evolving snack industry and the pivotal role played by corn snack machines in meeting consumer preferences. From traditional snack manufacturing methods to the cutting-edge technology integrated into modern machines, the evolution of corn snack production reflects a relentless pursuit of quality, efficiency, and versatility. As we embark on this exploration, we will delve into the latest advancements and emerging trends shaping the corn snack machine landscape in 2024.

Emerging Trends and Progress Predictions of Corn Snack Machinery Technology in 2024

In the realm of corn snack machine technology, the landscape is constantly evolving to meet the demands of a dynamic market. As we venture into 2024, several emerging trends and progress predictions are reshaping the future of corn snack production.

1. Integration of Artificial Intelligence and Machine Learning:

In 2024, we anticipate a significant leap forward in the integration of artificial intelligence (AI) and machine learning (ML) algorithms into corn snack machines. These advanced technologies will enable machines to analyze data in real-time, optimize production parameters, and even predict maintenance needs, thereby enhancing efficiency and minimizing downtime.

2. Enhanced Customization Capabilities:

Consumer preferences for personalized and unique snack experiences continue to drive the development of corn snack machines with enhanced customization capabilities. In 2024, we foresee machines equipped with modular components and interchangeable parts, allowing manufacturers to swiftly adapt to changing market trends and offer a diverse range of corn snack varieties.

3. Sustainable Manufacturing Practices:

With a growing emphasis on sustainability and environmental responsibility, manufacturers are increasingly incorporating eco-friendly features into corn snack machines. By 2024, we expect to see advancements in energy-efficient designs, waste reduction technologies, and recyclable materials, aligning with global efforts towards a greener and more sustainable future.

4. IoT Connectivity and Remote Monitoring:

The Internet of Things (IoT) is revolutionizing the way corn snack machines are monitored and managed. In 2024, these machines will be equipped with IoT sensors and connectivity features, enabling remote monitoring, predictive maintenance, and real-time performance optimization. This connectivity not only improves operational efficiency but also facilitates proactive decision-making and resource allocation.

5. Focus on Food Safety and Compliance:

In an increasingly regulated food industry, corn snack machine manufacturers are prioritizing food safety and compliance with stringent quality standards. By 2024, we anticipate the integration of advanced sanitation systems, hygiene protocols, and traceability measures into these machines, ensuring the production of safe and high-quality corn snacks that meet regulatory requirements and consumer expectations.

In conclusion, the year 2024 holds immense promise for the corn snack machine industry, with advancements in technology, sustainability, customization, and food safety reshaping the landscape of corn snack production. By embracing these emerging trends and progress predictions, manufacturers can stay ahead of the curve and deliver innovative solutions that meet the evolving needs of consumers in the years to come.

Versatility and Customization of Corn Snack Production

Corn snack production has seen a remarkable evolution over the years, and in 2024, the versatility and customization options offered by corn snack machines have reached unprecedented levels. This section will delve into the various aspects of versatility and customization in corn snack production, highlighting the capabilities and innovations driving this trend.

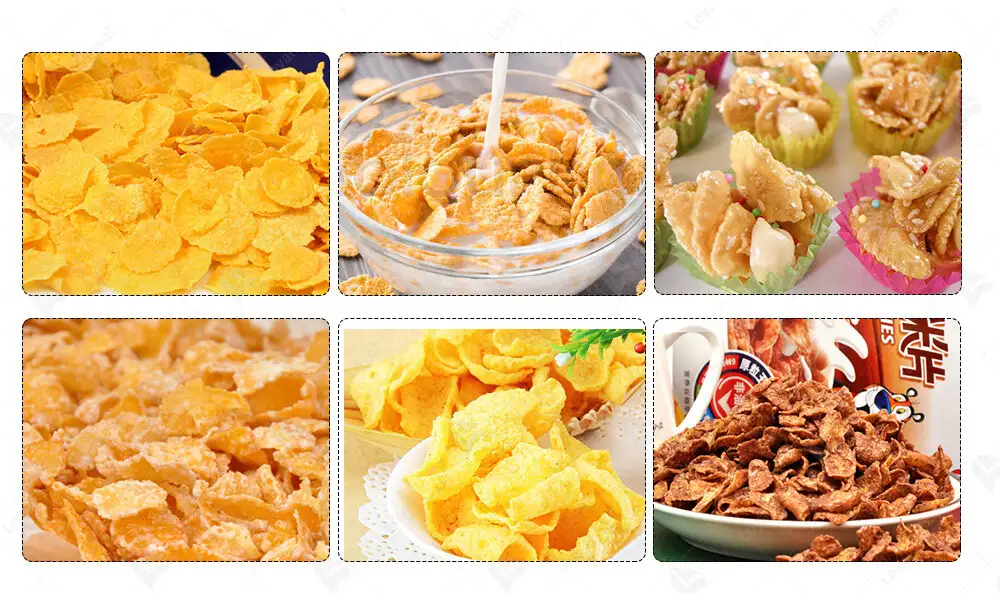

One of the key features of modern corn snack machines is their ability to produce a wide range of snack varieties with customized flavors, shapes, and textures. These machines are equipped with advanced technologies that allow for precise control over every aspect of the production process, from ingredient mixing to shaping and frying.

Versatility in Flavor Options:

In 2024, consumers are demanding more diverse and adventurous flavor experiences, and corn snack machines are rising to the occasion. These machines can accommodate a myriad of flavorings, including classic options like cheese and barbecue, as well as more exotic choices such as wasabi or truffle. Manufacturers can easily adjust the flavoring process to cater to changing consumer preferences and market trends.

Customization of Shapes and Textures:

Gone are the days of uniform, mass-produced corn snacks. With modern corn snack machines, manufacturers have the freedom to create snacks in a variety of shapes and textures. Whether it's traditional shapes like rings or squares, or innovative designs inspired by nature or pop culture, these machines can bring any vision to life. Moreover, they can adjust the texture of the snacks to meet specific preferences, from crispy and crunchy to light and airy.

Adaptability to Market Trends:

One of the hallmarks of a successful snack manufacturer is the ability to adapt quickly to changing market trends. Corn snack machines equipped with flexible production capabilities enable manufacturers to capitalize on emerging trends and seasonal demands. Whether it's a limited-time flavor promotion or a special holiday-themed snack, these machines can quickly adjust production to meet consumer expectations and capitalize on market opportunities.

Integration of Smart Technologies:

In the ever-evolving landscape of food production, corn snack machines are incorporating smart technologies to enhance versatility and customization further. Artificial intelligence and machine learning algorithms analyze consumer data and feedback to predict future flavor trends, allowing manufacturers to stay ahead of the curve. Additionally, IoT-enabled machines offer real-time monitoring and remote control capabilities, enabling seamless adjustments and optimization of production processes.

Work Flow of Corn Snacks

1. Raw Material Preparation:

- The work flow of corn snacks begins with the careful selection and processing of high-quality corn flour. This finely ground cornmeal serves as the primary ingredient for creating the base mixture used in snack production.

- Manufacturers prioritize the sourcing of premium corn flour to ensure consistent taste and texture in the final product. Rigorous quality control measures are implemented to assess factors such as moisture content, particle size, and purity.

2. Mixing and Flavoring:

- Once the corn flour is prepared, it is mixed with water and other ingredients to form a dough-like consistency. This mixture serves as the foundation for the creation of various corn snack shapes and textures.

- The versatility of corn snack machines allows for the incorporation of a wide range of flavors and seasonings. From classic salted varieties to more adventurous options like cheese, barbecue, or chili, manufacturers can customize the flavor profile to cater to diverse consumer preferences.

3. Extrusion and Shaping:

- The prepared dough is then fed into the extrusion chamber of the corn snack machine, where it undergoes high pressure and temperature to transform into its desired form.

- Specialized dies and molds are used to shape the extruded dough into familiar corn snack shapes, such as curls, twists, or rings. Precision engineering ensures consistent sizing and texture throughout the production process.

4. Frying or Baking:

- After shaping, the corn snacks enter the cooking stage, where they are either fried in oil or baked in an oven. This step is crucial for achieving the signature crunchiness and golden brown color associated with corn snacks.

- Manufacturers carefully control cooking time and temperature to ensure uniformity and avoid overcooking or burning. Advanced corn snack machines feature precise temperature control and monitoring systems for optimal results.

5. Seasoning and Packaging:

- Once cooked to perfection, the corn snacks undergo a final seasoning process to enhance their flavor profile. This may involve spraying or tumbling the snacks with additional seasoning blends to achieve the desired taste intensity.

- Finally, the seasoned corn snacks are carefully packaged into individual servings or bulk containers, ready to be distributed to eager consumers. Packaging materials are chosen to preserve freshness and extend shelf life while maintaining product integrity.

Efficiency and Sustainability of Corn Snack Production

When it comes to the efficiency and sustainability of corn snack production, every step of the process matters, starting from the raw material: corn flour. In 2024, advancements in technology have enabled manufacturers to optimize their production lines for maximum efficiency while minimizing their environmental footprint.

Optimized Processing with Corn Flour:

The use of corn flour as the primary ingredient in corn snack production offers several advantages. Firstly, corn flour provides a consistent texture and flavor profile, ensuring uniformity in the final product. Secondly, it allows for better control over the manufacturing process, leading to higher efficiency and reduced wastage.

Streamlined Production Line:

In modern corn snack machines, efficiency is paramount. Advanced automation systems streamline the production process, from mixing the ingredients to shaping and baking the snacks. By minimizing manual intervention and maximizing throughput, manufacturers can achieve higher production volumes with fewer resources.

Energy-Efficient Technologies:

Sustainability is a key focus in 2024, and corn snack manufacturers are embracing energy-efficient technologies to reduce their carbon footprint. This includes the use of energy-efficient motors and heating elements, as well as the implementation of smart controls to optimize energy usage throughout the production cycle.

Waste Reduction Strategies:

Minimizing waste is essential for both efficiency and sustainability. Corn snack production lines are equipped with sensors and monitoring systems to detect and address issues such as product defects or overproduction in real-time. Additionally, by utilizing by-products or optimizing packaging, manufacturers can further reduce waste generation.

Environmental Impact Mitigation:

Beyond the production process itself, manufacturers are also taking steps to mitigate the environmental impact of corn snack production. This includes sourcing corn from sustainable farms, implementing water recycling systems, and exploring alternative packaging materials that are biodegradable or recyclable.

Advantages of corn snack machine

Advantages of Corn Snack Machine |

1. Efficiency:Corn snack machines are highly efficient, capable of producing large quantities of snacks in a relatively short period. With automated processes and precise control systems, they minimize production time and labor costs. |

2. Versatility:These machines offer versatility in snack production, allowing for a wide range of corn snack varieties to be manufactured. From different shapes and sizes to various flavors and coatings, the possibilities are endless, catering to diverse consumer preferences. |

3. Customization:One of the key advantages of corn snack machines is their ability to customize snacks according to specific customer requirements. Whether it's adjusting the seasoning levels, altering the texture, or creating unique shapes, manufacturers can tailor their products to meet market demands effectively. |

4. Consistency:With advanced technology and precise manufacturing processes, corn snack machines ensure consistency in product quality and characteristics. Each batch of snacks is uniform in taste, texture, and appearance, enhancing consumer satisfaction and brand reputation. |

5. Cost-Effectiveness:Despite their initial investment cost, corn snack machines offer long-term cost savings through increased efficiency, reduced labor expenses, and minimized wastage. Their high productivity and low maintenance requirements contribute to a favorable return on investment over time. |

6. Food Safety:Maintaining food safety standards is paramount in snack manufacturing, and corn snack machines excel in this aspect. With hygienic design features, easy-to-clean surfaces, and strict adherence to sanitation protocols, they ensure the production of safe and hygienic snacks for consumers. |

7. Innovation:The continuous innovation in corn snack machine technology drives improvements in snack quality, production efficiency, and sustainability. Manufacturers are constantly developing new features, such as advanced control systems, energy-efficient components, and smart monitoring capabilities, to stay ahead of the competition and meet evolving market demands. |

Regulatory Compliance and Food Safety

Ensuring regulatory compliance and food safety standards is paramount in the operation of corn snack machines in 2024. As these machines play a crucial role in the production of snack foods, adherence to regulations is not just a legal requirement but also essential for maintaining consumer trust and brand reputation.

1. Understanding Regulatory Requirements:

To operate corn snack machines effectively, it's imperative to have a comprehensive understanding of the regulatory landscape governing food production. This includes local, national, and international regulations related to food safety, hygiene, labeling, and packaging.

2. Adhering to Food Safety Standards:

Compliance with food safety standards such as Hazard Analysis and Critical Control Points (HACCP) is non-negotiable. Corn snack machine operators must implement robust food safety management systems to identify, evaluate, and control food safety hazards throughout the production process.

3. Quality Assurance Measures:

In addition to meeting regulatory requirements, corn snack machine operators should implement quality assurance measures to ensure consistent product quality and safety. This may involve regular testing of raw materials, finished products, and production equipment to detect any contamination or defects.

4. Documentation and Record-Keeping:

Maintaining accurate documentation and records is essential for demonstrating compliance with regulatory requirements. This includes records of ingredient sourcing, production processes, equipment maintenance, and quality control measures. These records not only serve as proof of compliance but also provide valuable insights for continuous improvement.

5. Employee Training and Education:

Proper training and education of personnel operating corn snack machines are critical for maintaining food safety standards. Employees should receive comprehensive training on hygiene practices, equipment operation, sanitation procedures, and emergency response protocols to minimize the risk of contamination and ensure safe production practices.

6. Audits and Inspections:

Regular audits and inspections play a vital role in verifying compliance with regulatory requirements and identifying areas for improvement. Internal audits conducted by trained personnel and external inspections by regulatory authorities help ensure that corn snack machine operations meet or exceed established standards.

7. Continuous Improvement and Adaptation:

Finally, corn snack machine operators should embrace a culture of continuous improvement and adaptation to evolving regulatory requirements and industry best practices. This involves staying informed about updates to regulations, investing in advanced technologies, and fostering a proactive approach to food safety and compliance.

In conclusion, regulatory compliance and food safety are integral aspects of operating corn snack machines in 2024. By prioritizing adherence to regulations, implementing robust food safety measures, and fostering a culture of continuous improvement, corn snack machine operators can ensure the production of safe, high-quality snack products that meet consumer expectations and regulatory standards.

Post-Maintenance Guide for Corn Snack Machine

After investing in a cutting-edge corn snack machine, it's crucial to ensure its longevity and optimal performance through regular maintenance. In this post-maintenance guide, we'll outline essential steps and best practices to keep your machine running smoothly in 2024 and beyond.

1. Inspection and Cleaning Procedures:

Regular inspection and cleaning are fundamental to the upkeep of your corn snack machine. Begin by carefully examining all components, including the extruders, seasoning systems, and conveyor belts. Look for any signs of wear, damage, or residue buildup. Use appropriate cleaning agents and equipment to remove any accumulated debris or food particles. Pay special attention to areas prone to accumulation, such as nozzles and corners, to maintain hygiene standards and prevent contamination.

2. Lubrication and Calibration:

Proper lubrication is essential for the smooth operation of your corn snack machine. Regularly lubricate moving parts, such as bearings and gears, to reduce friction and prevent premature wear. Follow manufacturer guidelines for lubricant selection and application to ensure compatibility and effectiveness. Additionally, calibrate sensors and control systems periodically to maintain accuracy and consistency in processing parameters. This ensures that your machine continues to produce high-quality corn snacks efficiently.

3. Troubleshooting and Problem-Solving:

Even with regular maintenance, issues may arise with your corn snack machine. Develop a systematic approach to troubleshooting to identify and address common problems promptly. Keep detailed records of maintenance activities and performance metrics to facilitate troubleshooting and root cause analysis. Establish clear communication channels with equipment suppliers or service providers for timely assistance and resolution of technical challenges. By addressing issues proactively, you can minimize downtime and maintain productivity.

4. Safety Measures and Compliance:

Ensuring the safety of operators and compliance with regulatory requirements is paramount in corn snack machine maintenance. Provide comprehensive training for operators on proper machine operation, safety protocols, and emergency procedures. Conduct regular risk assessments and safety audits to identify potential hazards and implement preventive measures. Stay updated on industry regulations and compliance standards to ensure adherence to food safety and quality guidelines. By prioritizing safety and compliance, you can protect both your employees and your business reputation.

5. Performance Optimization and Upgrades:

To stay competitive in the snack industry, consider opportunities for performance optimization and upgrades for your corn snack machine. Stay informed about the latest advancements and best practices through engagement with industry experts and equipment manufacturers. Explore options for software updates, equipment upgrades, or process refinements to enhance efficiency and reliability. Additionally, consider investing in additional features or accessories, such as automated cleaning systems or predictive maintenance technologies, to further improve your machine's performance and longevity.

Reference materials

1. Food Engineering Magazine

Website: [https://www.foodengineeringmag.com/]

2. Food Processing Magazine

Website: [https://www.foodprocessing.com/]

3. Institute of Food Technologists (IFT)

Website: [https://www.ift.org/]

4. American Society of Agricultural and Biological Engineers (ASABE)

Website: [https://www.asabe.org/]

5. European Federation of Food Science and Technology (EFFoST)

Website: [https://effost.org/]