Everything You Need to Know About Cookie Making Machine

Introduction to Cookie Making Machines

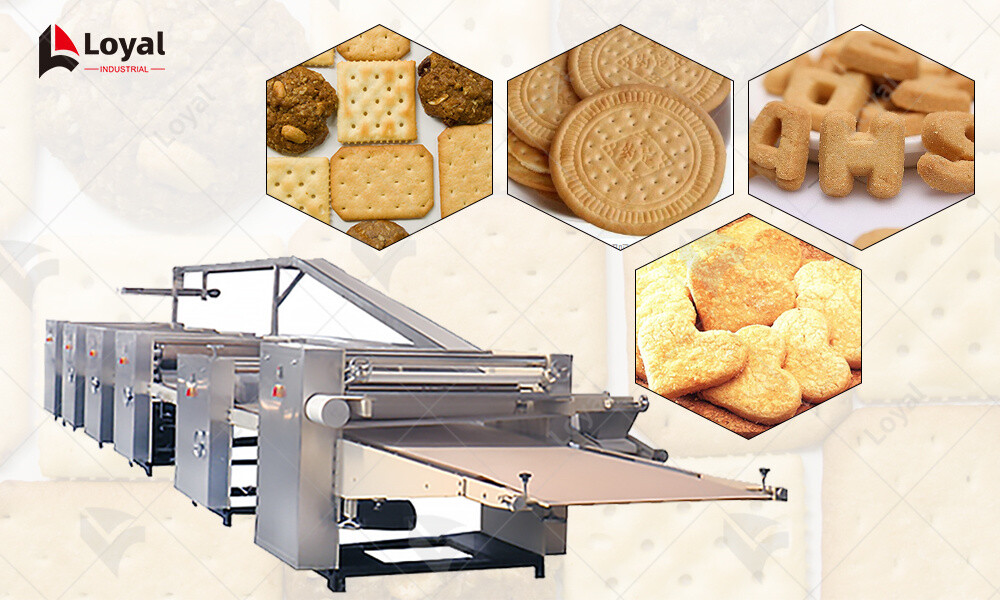

In the modern food production industry, the cookie making machine has become an essential piece of equipment for bakeries and large-scale cookie manufacturers. These machines are designed to streamline the cookie production process, ensuring consistency in size, shape, and texture while significantly reducing manual labor. Whether you're producing classic chocolate chip cookies or intricate designs for festive occasions, a cookie making machine can handle a variety of dough types and production requirements.

Cookie making machines come equipped with advanced features that cater to both small-scale artisanal bakers and large industrial operations. They offer precise control over ingredient mixing, dough depositing, shaping, and baking. This precision not only enhances the quality of the cookies but also increases production efficiency, allowing businesses to meet high demands without compromising on product quality.

Investing in a cookie making machine is a strategic decision for any bakery aiming to scale up production. These machines are designed with user-friendly interfaces and robust construction, ensuring longevity and ease of maintenance. By automating key aspects of cookie production, businesses can focus on innovation and expanding their product lines.

Types of Cookie Making Machines

The variety of cookie making machines available on the market caters to different production needs and scales. Below is a table summarizing the primary types of cookie making machines and their key features:

Type of Machine | Description | Key Features |

Wire Cut Machines | These machines are ideal for producing cookies with intricate shapes and designs. They use a wire to cut the dough into uniform pieces. | Precise cutting, adjustable wire speed, suitable for soft dough. |

Rotary Moulding Machines | Perfect for high-volume production, these machines use a rotating drum with moulds to shape cookies from dough. | High-speed production, consistent shape, easy mould change. |

Depositor Machines | These machines deposit cookie dough onto baking trays in precise amounts. They are versatile and can handle various dough consistencies. | Adjustable deposit size, multi-head options, ideal for soft dough. |

Drop Machines | Used for making drop cookies, these machines ensure uniform size and shape by dropping measured amounts of dough onto baking trays. | Uniform dropping, adjustable drop size, easy to operate. |

Extrusion Machines | Suitable for cookies with different shapes and sizes, these machines extrude dough through various dies to create the desired cookie shapes. | Variety of shapes, consistent extrusion, suitable for stiff dough. |

Sandwiching Machines | Specifically designed for sandwich cookies, these machines can deposit filling between two cookies automatically, increasing production speed. | Automatic filling, precise alignment, easy to clean. |

Each type of cookie making machine offers unique advantages depending on the specific requirements of the production process. Wire cut machines are excellent for artisanal cookies with detailed designs, while rotary moulding machines are preferred for mass production due to their speed and efficiency. Depositor and drop machines provide versatility and precision, making them ideal for various cookie recipes.

For businesses looking to expand their cookie product offerings, investing in a combination of these machines can provide the flexibility needed to innovate and diversify their product lines. The advanced technology and automation capabilities of modern cookie making machines not only enhance production efficiency but also ensure consistent quality, helping businesses meet the ever-growing consumer demand for high-quality cookies.

How Cookie Making Machines Work

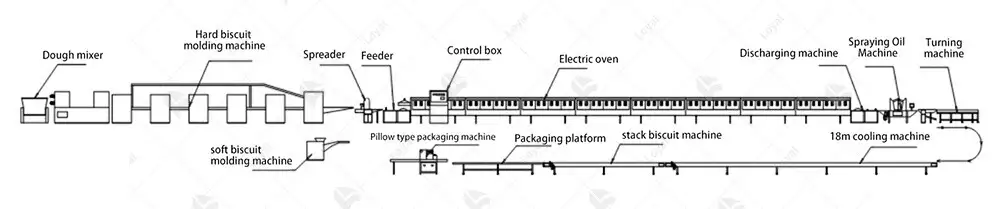

Cookie making machines are essential in the modern food industry, offering efficiency, consistency, and scalability for cookie production. These machines are designed to handle various stages of the cookie-making process, from dough mixing to baking and packaging. Understanding how these machines work can help businesses optimize their production lines and ensure high-quality products.

Dough Preparation: The first step in the cookie-making process is dough preparation. Cookie making machines often include integrated mixers that combine ingredients such as flour, sugar, butter, and eggs. These mixers are equipped with precise control systems to ensure the dough is mixed uniformly, which is crucial for producing cookies with consistent texture and flavor.

Dough Extrusion and Shaping: Once the dough is prepared, it is transferred to the extrusion section of the machine. Here, the dough is pushed through molds or dies to create cookies of specific shapes and sizes. Advanced cookie making machines allow for quick changes in molds, enabling the production of various cookie designs without significant downtime. This flexibility is vital for meeting diverse market demands.

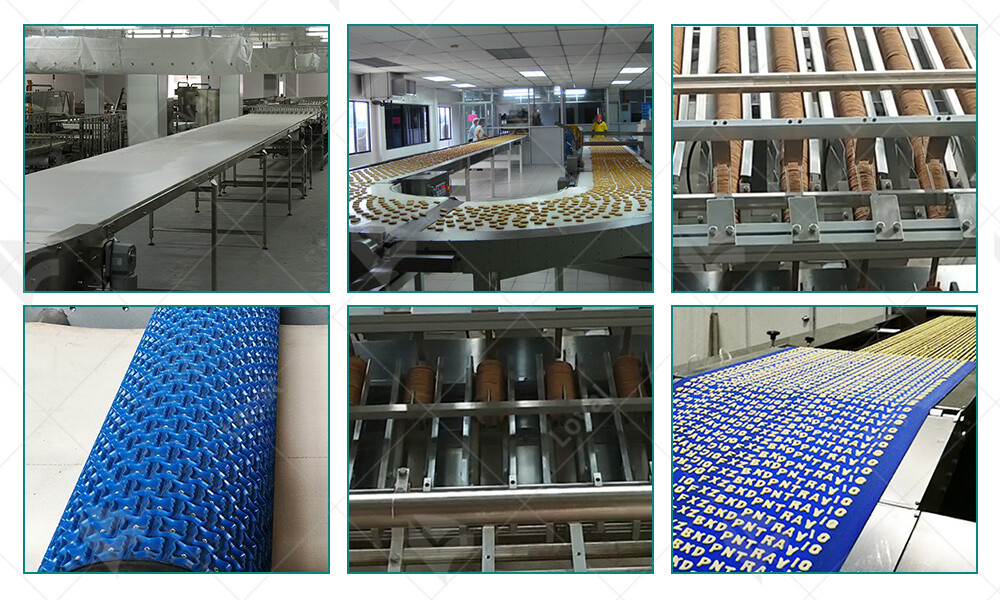

Baking: After shaping, the cookies are conveyed to the baking section. Modern cookie making machines feature tunnel ovens or rotary ovens that provide even heat distribution, ensuring uniform baking. Temperature and baking time can be precisely controlled, which is essential for achieving the desired cookie texture, whether it's soft and chewy or crisp and crunchy.

Cooling and Packaging: Once baked, cookies are transferred to cooling conveyors to bring them to room temperature. Proper cooling is necessary to prevent moisture retention, which can affect the cookies' shelf life. Finally, the cookies are packaged using automated systems. Cookie making machines can be integrated with packaging machines to streamline the process, reducing manual labor and increasing production efficiency.

Maintenance Tips for Cookie Making Machines

Proper maintenance of cookie making machines is crucial for ensuring their longevity and optimal performance. Regular maintenance helps prevent unexpected breakdowns and keeps the production line running smoothly. Below are some essential maintenance tips presented in a table format for easy reference:

Maintenance Task | Frequency | Description |

Cleaning | Daily | Clean all parts that come in contact with dough and cookies to prevent buildup and contamination. |

Lubrication | Weekly | Apply food-grade lubricants to moving parts to reduce friction and wear. |

Inspection | Monthly | Inspect belts, rollers, and molds for signs of wear and tear, and replace if necessary. |

Calibration | Quarterly | Calibrate control systems and sensors to ensure accurate dough mixing and shaping. |

Electrical System Check | Biannually | Check wiring and connections for any signs of damage or loose connections. |

Full System Overhaul | Annually | Perform a comprehensive check and service of the entire machine, including replacing worn parts and updating software. |

By following these maintenance tips, businesses can ensure their cookie making machines operate efficiently and produce high-quality cookies consistently. Regular upkeep not only extends the lifespan of the machinery but also minimizes downtime, thereby maximizing productivity.

Innovations in Cookie Making Technology

The cookie making machine industry has experienced significant advancements in recent years, driven by technological innovations aimed at enhancing efficiency, consistency, and quality. These innovations have revolutionized the way cookies are manufactured, catering to both large-scale industrial operations and small bakeries.

1. Automation and Robotics: Modern cookie making machines incorporate advanced automation and robotics, allowing for precise control over the production process. Automated systems can handle everything from dough mixing and shaping to baking and cooling, significantly reducing manual labor and minimizing human error. This results in consistent cookie quality and higher production rates.

2. Smart Technology Integration: The integration of smart technology into cookie making machines has made it possible to monitor and adjust various parameters in real-time. Sensors and IoT devices collect data on temperature, humidity, and dough consistency, enabling operators to make immediate adjustments. This ensures optimal baking conditions and enhances the overall quality of the cookies.

3. Energy Efficiency: Recent innovations have focused on making cookie making machines more energy-efficient. Newer models are designed to consume less power while maintaining high performance. Energy-efficient ovens and motors not only reduce operational costs but also contribute to a smaller environmental footprint.

4. Versatility and Customization: Today's cookie making machines are highly versatile, capable of producing a wide range of cookie shapes and sizes. Advanced models come with interchangeable molds and cutters, allowing manufacturers to easily switch between different cookie designs. Customization options are also available, enabling unique branding and the creation of specialty cookies tailored to specific market demands.

Troubleshooting Common Issues

Even with advanced cookie making machines, operators may encounter various issues during production. The following table outlines some common problems and their potential solutions:

Issue | Possible Cause | Solution |

Uneven Baking | Inconsistent oven temperature | Calibrate the oven and ensure uniform heat distribution |

Dough Sticking to Molds | Insufficient lubrication or incorrect dough consistency | Apply non-stick spray, adjust dough formulation |

Irregular Cookie Shapes | Worn-out or misaligned molds | Inspect and replace molds, ensure proper alignment |

Cracked or Broken Cookies | Overbaking or improper dough mixing | Adjust baking time, check dough consistency |

Machine Jams | Dough too thick or foreign objects in the machine | Adjust dough thickness, inspect and clean machine |

Inconsistent Cookie Size | Inaccurate dough portioning | Calibrate portioning mechanism, ensure consistent dough feed |

Safety Standards for Cookie Making Machines

Ensuring safety in the operation of cookie making machines is paramount. Adherence to safety standards not only protects operators but also ensures the production of safe and hygienic food products.

1. Compliance with Regulatory Standards: Cookie making machines must comply with industry regulations such as the FDA (Food and Drug Administration) in the United States or the CE (Conformité Européene) marking in Europe. These regulations ensure that machines are constructed using food-grade materials and meet stringent safety and hygiene standards.

2. Safety Features and Guards: Modern cookie making machines are equipped with various safety features, including emergency stop buttons, safety guards, and interlocks. These features prevent accidents by stopping the machine if any unsafe conditions are detected. Regular maintenance and inspection of these safety components are crucial to ensure their proper functioning.

3. Operator Training: Proper training of personnel is essential for safe operation. Operators should be trained in machine operation, maintenance, and emergency procedures. Understanding the correct use of safety features and recognizing potential hazards can significantly reduce the risk of accidents.

4. Hygienic Design: Machines should be designed with hygiene in mind, incorporating easy-to-clean surfaces and minimizing crevices where food particles can accumulate. Stainless steel construction is commonly used due to its durability and ease of cleaning. Regular sanitation of the equipment helps prevent contamination and ensures the production of safe, high-quality cookies.

Environmental Impact of Cookie Making Machines

The environmental impact of cookie making machines is an important consideration for manufacturers and consumers alike. As industrial food production grows, understanding and mitigating the environmental footprint of these machines becomes crucial.

Energy Consumption: Cookie making machines typically consume a significant amount of energy during operation. This energy is used for mixing, shaping, baking, and packaging cookies. Manufacturers are increasingly looking for ways to reduce energy usage by implementing more efficient motors, better insulation, and advanced heating technologies. Energy-efficient cookie making machines can lower operating costs and reduce greenhouse gas emissions, contributing to a smaller carbon footprint.

Material Use and Waste: The materials used in the construction of cookie making machines, such as stainless steel and plastics, also impact the environment. Sustainable practices in the manufacturing process, such as using recycled materials and designing for durability, help in reducing waste. Additionally, optimizing the machine’s operation to minimize ingredient wastage can lead to more sustainable production processes.

Water Consumption: Some stages of cookie production, particularly cleaning and cooling, require significant water usage. Innovations in water recycling and reduction technologies can help lower the water footprint of cookie making machines. Using closed-loop water systems and more efficient cleaning processes are among the methods being adopted to conserve water.

Pollution and Emissions: During the operation of cookie making machines, emissions from fuel or electricity use, as well as from the baking process, can contribute to air pollution. Advanced filtering systems and the adoption of clean energy sources, like solar or wind power, can help mitigate these emissions. Manufacturers are also exploring ways to reduce volatile organic compounds (VOCs) released during baking, which can improve air quality.

Future Trends in Cookie Making Machines

As the food industry evolves, several future trends in cookie making machines are emerging, focusing on technology, efficiency, and customization.

Automation and Smart Technology: The integration of automation and smart technology is transforming cookie making machines. Features such as real-time monitoring, predictive maintenance, and automated quality control are becoming standard. These advancements allow for higher precision and consistency, reducing human error and increasing production efficiency. Smart cookie making machines can adjust parameters automatically based on ingredient quality and production conditions, ensuring optimal results.

Sustainability Innovations: Future cookie making machines will likely incorporate more sustainable practices. This includes using biodegradable materials for machine parts, enhancing energy and water efficiency, and implementing zero-waste manufacturing processes. Manufacturers are also exploring the use of renewable energy sources to power these machines, further reducing their environmental impact.

Customization and Flexibility: The demand for personalized and unique cookie products is driving the need for machines that offer greater customization and flexibility. Future cookie making machines will be able to quickly switch between different cookie types, sizes, and designs without significant downtime. This flexibility will allow bakeries to meet diverse consumer preferences and seasonal demands more efficiently.

Advanced Materials and Construction: The use of advanced materials, such as high-performance composites and nanomaterials, can improve the durability and performance of cookie making machines. These materials can offer better resistance to wear and tear, reducing maintenance needs and extending the lifespan of the machines. Innovations in machine construction will also focus on ease of disassembly and recycling, promoting a circular economy in the food machinery industry.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com