Everything You Need to Know About Breakfast Cereal Production Line Equipments in 2024

Introduction to Breakfast Cereal Production Line Equipments

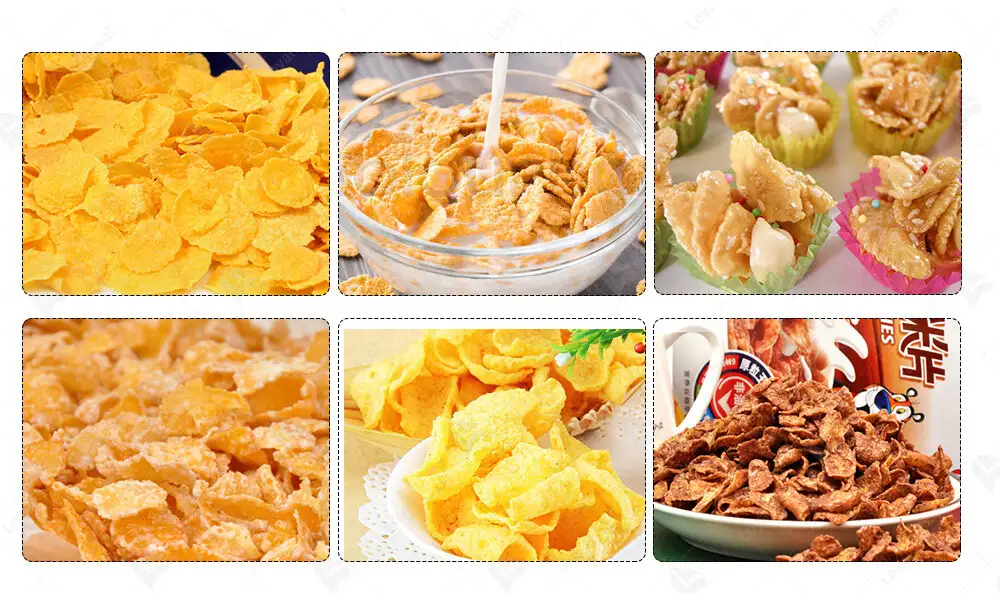

The breakfast cereal industry in 2024 is poised for significant advancements, driven by technological innovations and evolving consumer preferences. Specialized breakfast cereal production line equipments are crucial for meeting the demands of this dynamic market. These machines are designed to enhance efficiency, improve product quality, and ensure consistency in production.

Key innovations in breakfast cereal production line equipments include automated systems that reduce manual labor and minimize errors. Advanced machinery for mixing, cooking, and packaging plays a pivotal role in streamlining the production process. As an industrial food machinery expert, it is clear that investing in the latest breakfast cereal production line equipments is essential for staying competitive in this fast-paced industry.

Key Components of Breakfast Cereal Production Line Equipments

| Component | Description |

| Mixing and Blending Equipment | Ensures uniform distribution of ingredients, critical for consistent taste and texture. |

| Cooking and Extrusion Machinery | Applies heat and pressure to shape the cereal, crucial for producing puffed or shaped cereals. |

| Drying and Cooling Systems | Removes moisture to enhance shelf life and maintains texture quality by cooling the product evenly. |

| Flaking and Toasting Machines | Used to flatten and toast cereal flakes, essential for achieving the desired crunch and flavor. |

| Coating and Flavoring Equipment | Adds flavors, sweeteners, and other coatings to the cereal, enhancing taste and consumer appeal. |

| Packaging Solutions | Automates the packing process, ensuring the cereal is sealed and protected, maintaining freshness. |

Key Components of Breakfast Cereal Production Line Equipments

In the breakfast cereal industry, the efficiency and quality of production are heavily reliant on the right selection of production line equipment. Understanding the key components of these production line equipments is crucial for achieving optimal performance and maintaining high standards in cereal manufacturing.

Mixing and Blending Equipment

The first step in breakfast cereal production involves the precise mixing and blending of raw ingredients. High-performance mixers ensure that all components are uniformly combined, which is essential for consistency in flavor and texture. Advanced mixing equipments are designed to handle a wide variety of ingredients, including grains, sweeteners, and flavorings, ensuring a homogenous mixture.

Cooking and Extrusion Machinery

Cooking and extrusion are critical processes in the production of breakfast cereals. Extruders play a pivotal role in shaping and texturizing the cereal dough. Modern extrusion machinery is equipped with precise temperature and pressure controls, allowing for the production of a wide range of cereal shapes and sizes. These machines are essential for creating products like puffed, flaked, or shredded cereals.

Drying and Cooling Systems

After cooking and shaping, cereals need to be dried and cooled to achieve the desired crispness and shelf stability. Efficient drying systems, such as fluid bed dryers and belt dryers, remove moisture uniformly without compromising the cereal’s quality. Cooling systems then rapidly reduce the temperature of the cereals, preparing them for subsequent processing stages.

Flaking and Toasting Machines

For cereals like cornflakes, flaking and toasting are crucial steps. Flaking machines flatten cooked cereal dough into thin flakes, which are then toasted to enhance their flavor and texture. Modern flaking and toasting equipment ensure uniform thickness and consistent toasting, resulting in high-quality cereal products.

Coating and Flavoring Equipment

Many breakfast cereals are coated with sugar, honey, or other flavorings to enhance their taste. Coating and flavoring equipments apply these substances evenly, ensuring each piece of cereal is uniformly coated. Advanced systems can handle a variety of coating processes, from liquid applications to dry powder coatings.

Packaging Solutions

The final step in the production line is packaging. High-speed packaging machines ensure that cereals are packed efficiently and securely, maintaining freshness and preventing contamination. Modern packaging solutions often include features like resealable bags and portion control packaging, catering to consumer convenience and preferences.

Technological Advancements in Breakfast Cereal Production Line Equipments

The breakfast cereal production line equipments are witnessing rapid technological advancements in 2024, transforming the industry with innovative solutions that enhance efficiency and product quality. As an expert in industrial food machinery, it's essential to understand these technological developments to stay competitive and meet evolving consumer demands.

Automation and smart technologies are at the forefront of these advancements. Modern production lines are increasingly integrating advanced sensors, AI, and machine learning to optimize various processes. These technologies enable real-time monitoring and control, ensuring consistent product quality and minimizing downtime. For instance, automated systems can adjust cooking temperatures and times based on real-time data, ensuring that each batch of cereal is perfectly cooked.

Energy efficiency is another critical area of innovation. New breakfast cereal production line equipments are designed to consume less energy while maintaining high output levels. This not only reduces operational costs but also aligns with global sustainability goals. For example, advanced extrusion machines now feature energy-saving modes that significantly cut down on power usage during non-peak times.

Ingredient processing has also seen significant improvements. The latest machinery can handle a wider variety of ingredients, including whole grains, nuts, and dried fruits, allowing manufacturers to produce a diverse range of cereal products. These machines are equipped with precise dosing systems that ensure accurate ingredient proportions, enhancing the nutritional value and taste of the final product.

Quality control systems have become more sophisticated, incorporating technologies such as X-ray inspection and metal detection to ensure the highest standards of safety and quality. These systems can detect and remove contaminants from the production line, safeguarding consumers and maintaining the brand's reputation.

Selecting the Right Breakfast Cereal Production Line Equipments

When it comes to selecting the right breakfast cereal production line equipments in 2024, there are several critical factors that manufacturers must consider to ensure optimal performance and efficiency. As an industrial food machinery expert, understanding these factors is essential for making informed decisions.

Factors to Consider: Production Capacity, Scalability, and Flexibility

The first consideration is production capacity. Depending on the scale of your operations, you need equipment that can handle the desired output efficiently. High-capacity mixers, extruders, and packaging machines are essential for large-scale production, whereas smaller, more versatile equipment may be suitable for niche or startup operations.

Scalability is another crucial factor. Your breakfast cereal production line should be able to grow with your business. Investing in modular equipment that can be easily expanded or upgraded will save costs in the long run and allow for seamless adaptation to increased demand.

Flexibility in production is also important. With the growing trend towards customized and health-focused cereals, your equipment should be capable of handling a variety of ingredients and formulations. This includes machinery that can switch between different types of cereals, such as flakes, puffs, and granolas, without extensive reconfiguration.

Customization Options for Different Types of Cereals

The ability to customize production line equipment for different types of cereals is vital. Advanced breakfast cereal production line equipments offer features that allow for precise control over cooking, drying, and coating processes, ensuring consistency and quality across various cereal products. Look for equipment with adjustable settings and programmable controls to achieve the desired texture, flavor, and appearance for each type of cereal.

Cost Considerations and Return on Investment

Cost is always a significant factor when selecting breakfast cereal production line equipments. While it may be tempting to opt for cheaper machinery, it's important to consider the long-term return on investment. High-quality, durable equipment may have a higher upfront cost but will typically offer better performance, reduced downtime, and lower maintenance expenses over time. Calculate the total cost of ownership, including energy consumption, maintenance, and potential upgrades, to make a well-rounded investment decision.

Leading Manufacturers and Suppliers

Choosing equipment from reputable manufacturers and suppliers is essential for ensuring reliability and support. Look for companies with a proven track record in the breakfast cereal production industry and positive reviews from other manufacturers. Reliable suppliers will offer robust customer support, including installation services, training for your staff, and ongoing technical assistance to keep your production line running smoothly.

Maintenance and Operational Efficiency of Breakfast Cereal Production Line Equipments

Maintaining optimal performance and efficiency of breakfast cereal production line equipments in 2024 requires adherence to best practices, thorough training, proactive issue resolution, and timely upgrades. As an expert in industrial food machinery, ensuring smooth operations through effective maintenance strategies is crucial.

Best Practices for Equipment Maintenance and Longevity

To maximize the lifespan and reliability of breakfast cereal production line equipments, manufacturers and operators should implement rigorous maintenance schedules. This includes regular inspections, lubrication of moving parts, and calibration of sensors and control systems. Preventive maintenance helps identify potential issues before they escalate, minimizing downtime and production disruptions.

Training and Skill Requirements for Operational Staff

Equipping operational staff with the necessary skills and knowledge is essential for maintaining operational efficiency. Training programs should cover equipment operation, troubleshooting techniques, safety protocols, and emergency procedures. Well-trained staff can swiftly address issues, ensure equipment operates at peak performance, and uphold product quality standards.

Troubleshooting Common Issues

Despite preventive measures, occasional issues may arise in breakfast cereal production line equipments. Common challenges include equipment jamming, sensor malfunctions, and irregular product flow. Operators should be trained to troubleshoot these issues promptly to minimize downtime. Detailed troubleshooting guides and access to technical support can expedite problem resolution.

Importance of Regular Upgrades and Technological Updates

Innovation is constant in the food machinery industry, with advancements improving equipment efficiency and capabilities. Regular upgrades to software and hardware components enhance equipment reliability, energy efficiency, and product quality. Technological updates also ensure compliance with industry standards and regulatory requirements, positioning manufacturers at the forefront of technological advancements.

Ensuring maintenance and operational efficiency of breakfast cereal production line equipments not only boosts productivity but also enhances overall operational sustainability. By prioritizing maintenance practices, investing in staff training, promptly addressing issues, and embracing technological advancements, manufacturers can achieve optimal performance and meet consumer demand effectively.

Future Outlook for Breakfast Cereal Production Line Equipments

As we look ahead to 2024, the landscape of breakfast cereal production line equipments is poised for significant advancements. This sector plays a crucial role in the efficiency and quality of cereal manufacturing processes. As an expert in industrial food machinery, it's clear that several key trends will shape the future of these equipments.

Automation stands at the forefront of these advancements. In 2024, breakfast cereal production lines are expected to integrate more sophisticated automated systems. These systems streamline operations such as mixing, cooking, and packaging, enhancing production efficiency and consistency. Manufacturers are increasingly investing in smart technologies that optimize processes and minimize manual intervention.

Sustainability is another pivotal trend driving innovation in cereal production line equipments. With heightened global awareness of environmental impact, equipment manufacturers are focusing on energy-efficient designs and sustainable production practices. This includes the use of renewable energy sources and the reduction of waste throughout the production cycle, aligning with both regulatory requirements and consumer preferences.

Furthermore, customization capabilities are becoming essential in cereal production equipments. As consumer preferences diversify, equipments must be adaptable to produce a variety of cereal types, including gluten-free, organic, and fortified options. This requires versatile machinery that can handle different ingredients and processes without compromising efficiency or product quality.

In conclusion, the future outlook for breakfast cereal production line equipments in 2024 is characterized by advancements in automation, sustainability, and customization. These trends not only enhance operational efficiency but also position manufacturers to meet evolving consumer demands effectively.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/