Everything you Need to Know About Bread Crumbs Production Plant

Introduction to Bread Crumbs Production

Bread crumbs play a crucial role in the culinary world, enhancing the texture and flavor of a wide range of dishes. Understanding the intricacies of bread crumbs production plant operations can significantly impact the quality and efficiency of the end product. This article delves into the essential aspects of bread crumbs production, focusing on the machinery and processes involved.

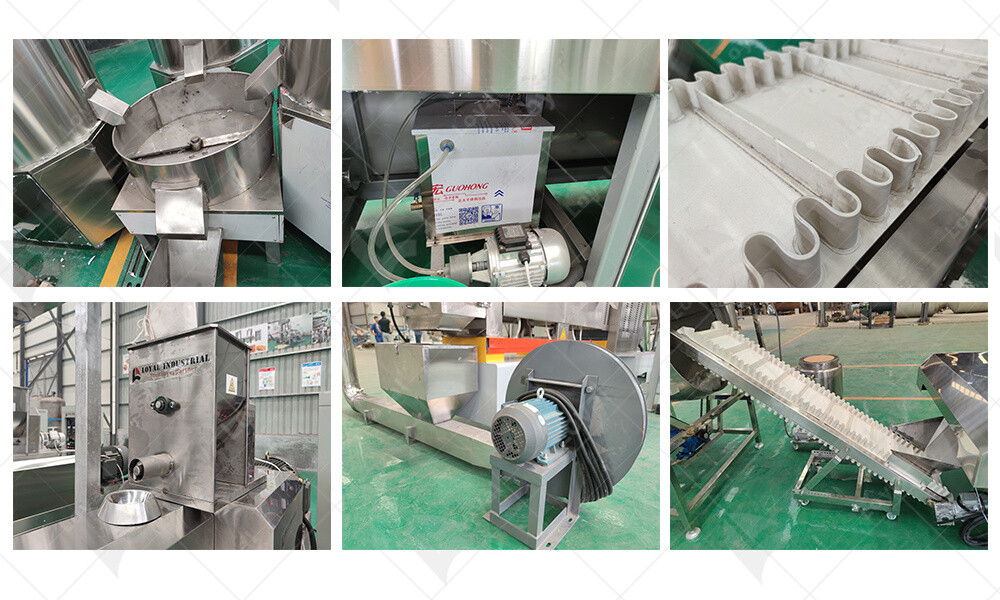

In a bread crumbs production plant, raw materials such as bread loaves are transformed into uniform crumbs through a series of precise steps. These steps include baking, drying, grinding, and sieving, each requiring specialized equipment to ensure consistent quality. The importance of each component and the role it plays in the production line cannot be overstated.

Investing in a well-designed bread crumbs production plant is essential for any business looking to produce high-quality bread crumbs on an industrial scale. From small-scale operations to large manufacturing units, understanding the key components and their functions will provide a competitive edge in the market.

Key Components of a Production Plant

Component | Description |

Bread Loaf Slicer | This machine slices bread loaves into uniform pieces, which is the first step in the bread crumbs production plant. The consistency in slicing ensures even baking and drying, leading to uniform crumbs. |

Baking Oven | The sliced bread is then baked to a specific moisture content, which is crucial for the subsequent grinding process. Advanced ovens allow for precise temperature and humidity control. |

Drying Conveyor | After baking, the bread slices are transferred to a drying conveyor. This component ensures that the bread reaches the optimal dryness level required for efficient grinding. |

Grinder | The dried bread slices are ground into crumbs using industrial grinders. The grinder’s settings can be adjusted to produce different crumb sizes, catering to various culinary needs. |

Sieve Shaker | Post-grinding, the bread crumbs are sieved to separate them into different sizes. This machine ensures that only uniformly sized crumbs are packaged, maintaining the product's quality. |

Packaging Machine | Finally, the bread crumbs are packaged using an automated packaging machine. This step ensures that the product is sealed properly, maintaining freshness and extending shelf life. |

Bread Crumbs Manufacturing Process Overview

The bread crumbs production plant operates through a series of well-coordinated steps to ensure the highest quality output. The process begins with the preparation of raw materials. Fresh bread, typically sourced from a bread production facility, is essential. This bread is sliced and dried to achieve the necessary texture.

Once dried, the bread is ground into crumbs. This grinding stage is critical, as it determines the final texture of the bread crumbs. The bread crumbs production plant utilizes specialized grinding machines that can be adjusted to produce various crumb sizes, from fine to coarse, depending on the intended use.

After grinding, the crumbs undergo a sieving process. This step ensures uniformity by separating crumbs based on size. The sieved crumbs are then baked to remove any remaining moisture, enhancing their shelf life and ensuring they are free from microbial contamination. The baking process also adds to the crispiness of the final product, which is a desirable attribute in many culinary applications.

Finally, the bread crumbs are cooled and packaged. The packaging phase is designed to preserve the product’s freshness and extend its shelf life. Modern bread crumbs production plants use automated packaging systems that seal the crumbs in airtight bags, ready for distribution to retailers and end-users.

Choosing the Right Equipment for Production

Choosing the appropriate equipment for a bread crumbs production plant is vital for efficiency and product quality. Here’s a detailed breakdown of the essential machinery required:

Equipment | Function | Key Features |

Bread Slicer | Cuts fresh bread into uniform slices | Adjustable thickness, high-speed operation |

Drying Oven | Removes moisture from bread slices | Temperature control, even heat distribution |

Grinder | Converts dried bread into crumbs | Variable grinding settings, durable construction |

Sieving Machine | Sorts crumbs by size | Multi-layer sieves, easy to clean |

Baking Oven | Ensures crumbs are dry and crispy | Precise temperature control, consistent heating |

Cooling Conveyor | Cools baked crumbs before packaging | Gentle handling, speed adjustable |

Packaging Machine | Seals crumbs in airtight bags | Automated, various packaging sizes, vacuum sealing option |

Each piece of equipment plays a crucial role in the overall production process. The bread slicer ensures uniform slices, which are essential for consistent drying and grinding. The drying oven’s ability to maintain a consistent temperature is critical for removing moisture without burning the bread. The grinder’s versatility allows for the production of different crumb textures, catering to diverse culinary needs.

The sieving machine guarantees that the final product meets size specifications, while the baking oven’s precision ensures that crumbs are perfectly crispy. The cooling conveyor is vital for preventing the crumbs from clumping due to residual heat, and the packaging machine protects the final product from environmental factors that could affect its quality.

Quality Control and Standards Compliance

In any bread crumbs production plant, maintaining high standards of quality control and ensuring compliance with industry standards are critical. Firstly, the plant must adhere to Good Manufacturing Practices (GMP) which cover all aspects of production from raw material sourcing to final packaging. These practices ensure that the bread crumbs produced are safe for consumption and meet all regulatory requirements.

Additionally, the bread crumbs production plant should implement a Hazard Analysis Critical Control Point (HACCP) system. This involves identifying potential hazards in the production process and establishing critical control points where these hazards can be effectively managed. Regular monitoring and verification activities are essential to ensure the HACCP plan is functioning correctly.

Thirdly, compliance with international food safety standards, such as ISO 22000, is necessary for a bread crumbs production plant. This certification demonstrates a commitment to food safety management and continuous improvement. Regular audits and inspections by certified bodies ensure that the plant consistently meets these high standards.

Lastly, quality control laboratories within the bread crumbs production plant should conduct routine tests on both raw materials and finished products. These tests include microbiological, physical, and chemical analyses to ensure that the bread crumbs meet the desired quality and safety standards.

Maintenance of Production Machinery

A well-maintained machinery setup is vital for the efficiency and longevity of a bread crumbs production plant. Below is a detailed table outlining the key maintenance tasks and their recommended schedules:

Machinery Component | Maintenance Task | Frequency | Responsible Personnel |

Mixers and Blenders | Inspect and lubricate moving parts | Weekly | Maintenance Engineer |

Ovens | Clean heating elements and check temperature calibration | Monthly | Maintenance Technician |

Conveyors | Check belt tension and alignment; lubricate bearings | Bi-weekly | Maintenance Staff |

Packaging Machines | Inspect and replace worn-out parts; test sealing mechanisms | Monthly | Mechanical Engineer |

Sifters and Sieves | Clean thoroughly and inspect for wear and tear | Bi-weekly | Maintenance Staff |

Storage Silos | Inspect for contamination; clean and sanitize | Monthly | Quality Control Team |

Metal Detectors | Test sensitivity and recalibrate if necessary | Weekly | Quality Control Team |

Cooling Tunnels | Check airflow and clean filters | Monthly | HVAC Technician |

Dust Collection Systems | Empty collection units and inspect filters | Bi-weekly | Maintenance Staff |

Electrical Systems | Inspect wiring and connections; test backup power | Quarterly | Electrical Engineer |

Innovations in Bread Crumbs Production Technology

In recent years, the bread crumbs production plant has seen significant technological advancements. Modern machinery now integrates automation to streamline the production process, significantly increasing efficiency and consistency. One of the key innovations is the use of high-speed mixers and automated ovens that ensure uniform baking and cooling of bread before it is ground into crumbs. This not only enhances product quality but also reduces labor costs and human error.

Another breakthrough in the bread crumbs production plant is the implementation of advanced drying technologies. Traditional methods often resulted in uneven moisture content, affecting the shelf life and texture of the final product. Today's plants utilize continuous drying systems with precise temperature control, ensuring optimal moisture levels and extending product durability.

Moreover, the advent of artificial intelligence (AI) and machine learning in the bread crumbs production plant has revolutionized quality control. Automated inspection systems equipped with AI can detect defects or inconsistencies in bread crumbs at various stages of production, ensuring only the highest quality product reaches the market. This has significantly reduced waste and improved overall efficiency.

Finally, energy-efficient equipment has become a cornerstone of innovation in the bread crumbs production plant. Modern machinery is designed to consume less energy while maintaining high production volumes. This not only reduces operational costs but also aligns with global efforts to minimize environmental impact, making the production process more sustainable.

Environmental Considerations and Sustainability

Sustainability is becoming increasingly important in the operation of a bread crumbs production plant. One major consideration is the sourcing of raw materials. Many plants are now prioritizing locally sourced, organic bread to reduce the carbon footprint associated with transportation and promote eco-friendly farming practices. This shift not only supports local economies but also ensures the raw materials are of the highest quality.

In the bread crumbs production plant, waste management is another critical environmental consideration. Modern plants are adopting comprehensive waste reduction strategies, such as recycling bread waste and utilizing by-products in animal feed or compost. This approach minimizes landfill contributions and turns potential waste into valuable resources, enhancing the plant’s sustainability profile.

Energy consumption is also a focal point for sustainability in the bread crumbs production plant. Energy-efficient technologies, such as low-energy ovens and LED lighting, are increasingly being adopted to reduce the plant's overall energy footprint. Additionally, some plants are investing in renewable energy sources, such as solar or wind power, to further decrease their reliance on non-renewable energy.

Water usage in a bread crumbs production plant is another area where sustainability can be improved. Implementing water recycling systems and using water-efficient equipment helps conserve this vital resource. Furthermore, treating and reusing wastewater within the plant can significantly reduce the environmental impact, ensuring the production process is as eco-friendly as possible.

Future Trends in Bread Crumbs Manufacturing

The bread crumbs production plant industry is evolving rapidly, driven by technological advancements and changing consumer preferences. One notable trend is the increasing automation within the production process. Modern bread crumbs production plants are integrating advanced machinery and robotics to enhance efficiency, reduce labor costs, and ensure consistent product quality. Automation not only speeds up production but also minimizes human error, leading to a more reliable and scalable operation.

Another emerging trend is the adoption of sustainable and eco-friendly practices. As environmental concerns grow, bread crumbs production plants are focusing on reducing waste, utilizing renewable energy sources, and implementing energy-efficient processes. This shift not only helps in complying with environmental regulations but also appeals to environmentally conscious consumers, thereby giving companies a competitive edge.

In terms of product innovation, there is a rising demand for diverse and customized bread crumb varieties. Consumers are looking for gluten-free, organic, and specialty bread crumbs that cater to various dietary needs and preferences. Bread crumbs production plants are investing in research and development to create unique formulations and flavors, meeting the niche demands of the market and expanding their product portfolios.

Finally, the integration of digital technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) is transforming the industry. These technologies enable real-time monitoring and data analysis, optimizing production processes and maintenance schedules. By leveraging IoT and AI, bread crumbs production plants can enhance operational efficiency, predict equipment failures before they occur, and maintain high standards of product quality.

Case Studies of Successful Production Plants

One exemplary bread crumbs production plant is located in Germany, where state-of-the-art automation technologies have revolutionized their manufacturing process. This plant utilizes robotic systems for mixing, baking, and packaging, significantly reducing labor costs and production time. Their commitment to automation has resulted in a 30% increase in output and a notable improvement in product consistency.

In Japan, a leading bread crumbs production plant has adopted sustainable practices that set a benchmark for the industry. By incorporating solar panels and utilizing biomass energy, this plant has reduced its carbon footprint by 40%. Additionally, they have implemented a zero-waste policy, ensuring that all by-products are either recycled or repurposed, which has garnered them significant recognition for their environmental stewardship.

A U.S.-based bread crumbs production plant has gained acclaim for its innovative product range, including gluten-free and organic options. By conducting extensive market research and investing in cutting-edge R&D facilities, this plant has successfully tapped into the health-conscious segment of the market. Their diversified product line has led to a 25% increase in market share over the past two years.

Lastly, a bread crumbs production plant in Italy exemplifies the successful integration of digital technologies. By implementing IoT sensors and AI-driven analytics, this plant has achieved unprecedented levels of operational efficiency. Real-time data collection and analysis have enabled predictive maintenance, reducing downtime by 20% and ensuring optimal performance of their machinery. This tech-forward approach has set a new standard for efficiency and reliability in the industry.

Reference

1.Baker Perkins - bakerperkins.com

2.GEA Group - gea.com

3.Heat and Control - heatandcontrol.com

4.Hosokawa Micron - hosokawamicron.com

5.Fritsch Group - fritsch-group.com