Everything You Need to Know About Biscuit Making Machine Price

Introduction to Biscuit Making Machines

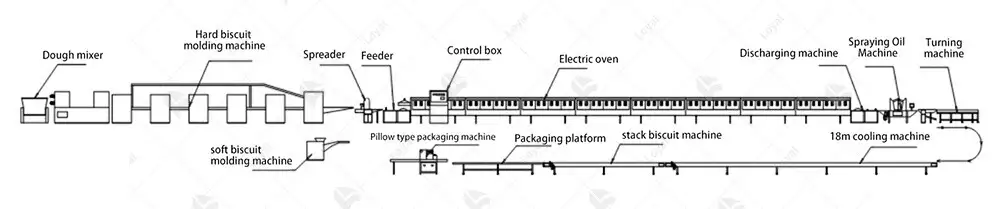

Biscuit manufacturing machines are essential equipment in the food industry, designed to automate the production process of various types of biscuits. These machines help in enhancing production efficiency, ensuring consistent quality, and reducing labor costs. From mixing dough to baking and cooling, biscuit making machines encompass a wide range of functionalities that cater to different production needs. Advanced biscuit manufacturing machines are equipped with modern technology to produce large quantities of biscuits with precise shapes and sizes, meeting the demands of both small-scale and large-scale production facilities.

The integration of automated systems in biscuit manufacturing machines has revolutionized the biscuit production industry. These machines come with programmable controls that allow operators to adjust parameters such as baking time, temperature, and dough thickness, ensuring each batch of biscuits meets specific quality standards. Moreover, the use of robust materials in their construction ensures durability and longevity, making them a valuable investment for any biscuit production business.

The demand for high-quality biscuits has led to continuous innovation in biscuit manufacturing technology. Modern biscuit making machines are designed to be energy-efficient and easy to maintain, minimizing downtime and operational costs. By incorporating features such as automated cleaning systems and user-friendly interfaces, manufacturers can focus on enhancing their product offerings while maintaining high production standards.

Factors Influencing Biscuit Making Machine Price

Several factors influence the price of a biscuit manufacturing machine, making it crucial for buyers to understand these elements before making a purchase. One of the primary factors is the machine's production capacity. Machines capable of producing larger quantities of biscuits per hour generally cost more due to their advanced features and higher output rates.

Another significant factor is the level of automation. Fully automated biscuit making machines, which require minimal human intervention, tend to be more expensive than semi-automated or manual machines. This is because automated machines incorporate advanced technologies such as touch screen controls, programmable logic controllers (PLCs), and automated ingredient feeders.

The material and build quality of the machine also play a vital role in determining its price. Machines made from high-quality stainless steel are more durable and resistant to corrosion, making them more costly. Additionally, the brand and manufacturer reputation can influence the price. Well-established manufacturers with a track record of producing reliable and efficient machines often charge a premium for their products.

Types of Biscuit Making Machines

There are various types of biscuit manufacturing machines available in the market, each designed to cater to specific production requirements. Some of the most common types include rotary moulding machines, wire cut machines, and tunnel ovens.

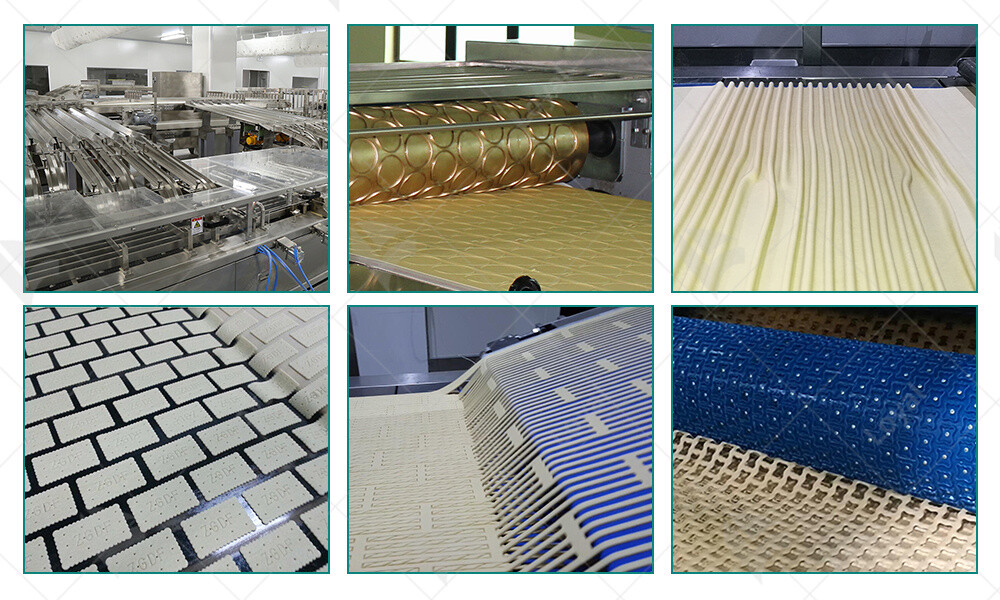

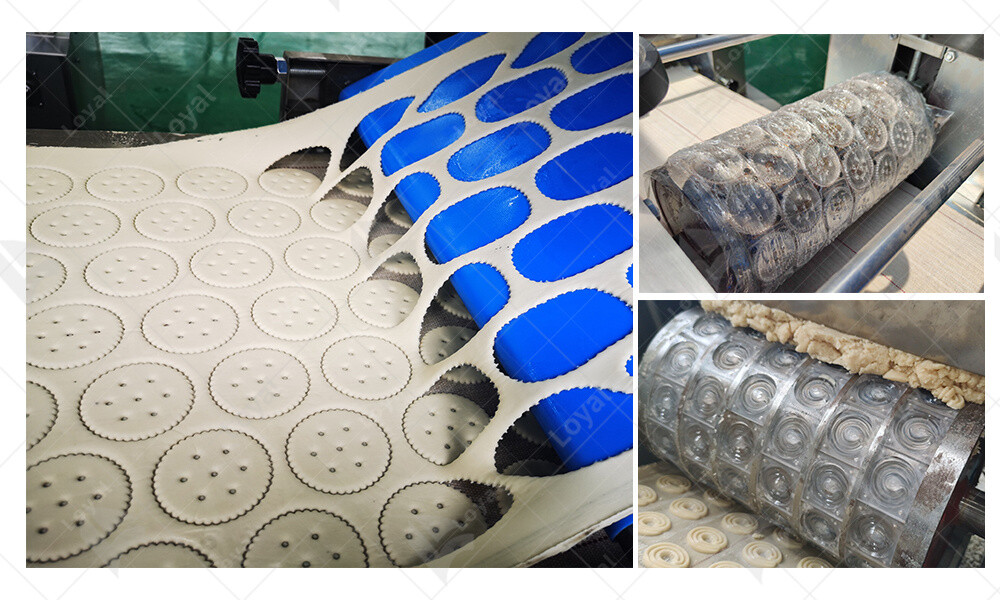

Rotary moulding machines are used to produce a wide range of soft dough biscuits. These machines use a rotary mould to shape the dough into the desired biscuit form before it is transferred to the baking oven. They are ideal for producing high volumes of biscuits with intricate designs and consistent thickness.

Wire cut machines are suitable for producing biscuits with a crumbly texture. These machines work by extruding dough through a die, then cutting it into uniform pieces using a wire. This method allows for precise control over the size and shape of each biscuit, making it perfect for creating a variety of biscuit types.

Tunnel ovens are an essential component of large-scale biscuit production lines. These ovens provide consistent baking conditions through controlled temperature zones, ensuring even baking and optimal texture. Tunnel ovens are highly efficient and can handle continuous production, making them suitable for large-scale operations.

Leading Manufacturers and Brands

When it comes to biscuit manufacturing machines, several leading manufacturers dominate the market. These companies are renowned for their innovative technologies, high-quality machinery, and excellent customer support. One of the prominent names in this industry is LOYAL Company. LOYAL has established itself as a top player due to its robust engineering and reliable performance. Their machines are designed to handle various production capacities and biscuit types, making them a versatile choice for biscuit manufacturers.

LOYAL Company, along with other notable brands like Baker Perkins, GEA Group, and Polin, offer a range of machines that cater to different needs. These manufacturers ensure their machines comply with international standards and are equipped with the latest technology to improve efficiency and product quality. Choosing a well-known brand like LOYAL not only guarantees the durability and reliability of the machinery but also provides access to extensive customer service and maintenance support, which is crucial for uninterrupted production.

Comparing Prices Across Different Models

The price of a biscuit manufacturing machine can vary significantly based on several factors, including the machine’s specifications, production capacity, and additional features. Entry-level models designed for small-scale production might start at a lower price point, often in the range of $10,000 to $50,000. These machines are suitable for small bakeries or startups looking to produce a limited variety of biscuits.

Mid-range models, which offer greater versatility and higher production capacities, typically range from $50,000 to $200,000. These machines often come with advanced features such as automated dough mixing, cutting, and baking processes, which enhance efficiency and reduce manual labor.

High-end models designed for large-scale production can exceed $200,000. These machines are equipped with the latest technologies, such as programmable logic controllers (PLCs), touch-screen interfaces, and sophisticated quality control systems. They offer the highest production capacities, sometimes exceeding several tons of biscuits per day, and are ideal for large factories aiming for mass production.

It’s essential to compare the prices of different models while considering the specific needs of your production line. Investing in a more expensive machine can be justified by the long-term benefits of increased efficiency, higher output, and reduced labor costs.

How Production Capacity Affects Cost

Production capacity is one of the most critical factors influencing the cost of a biscuit manufacturing machine. Machines with higher production capacities tend to be more expensive due to their advanced engineering and the materials required to ensure durability and efficiency at scale.

Low-capacity machines are generally less costly because they are designed for smaller operations and fewer production hours. These machines might produce a few hundred kilograms of biscuits per day, which is sufficient for small to medium-sized businesses.

As production capacity increases, so does the complexity of the machinery. Medium-capacity machines, which can produce several tons of biscuits per day, incorporate more sophisticated technologies to handle the increased workload. This includes enhanced mixing and baking systems, better temperature control, and more robust construction materials. The price of these machines reflects these additional features and their ability to maintain consistent quality over long production runs.

High-capacity machines, designed for large-scale industrial production, are the most expensive. They are built to operate continuously with minimal downtime and can produce tens of tons of biscuits daily. These machines are equipped with the latest automation and quality control technologies to ensure efficiency and product uniformity. The initial investment in these high-capacity machines is significant, but the return on investment can be substantial for large manufacturers due to the economies of scale and the ability to meet high market demand.

Innovations in Biscuit Making Technology

The biscuit manufacturing machine industry has seen significant advancements in recent years. Modern machines are equipped with state-of-the-art technologies that enhance productivity, efficiency, and product quality. Here are some of the key innovations:

Automated Control Systems: These systems allow for precise control over the biscuit manufacturing process, ensuring consistent quality and reducing human error. Automated systems also facilitate real-time monitoring and adjustments, optimizing production efficiency.

Energy Efficiency: Newer models are designed to consume less energy, reducing operational costs and environmental impact. Energy-efficient motors and heating systems are now standard in advanced biscuit manufacturing machines.

Flexible Production Lines: Modern machines offer greater flexibility, allowing manufacturers to switch between different types of biscuits with minimal downtime. This flexibility is crucial for meeting market demands and catering to diverse consumer preferences.

Enhanced Hygiene Standards: Improved design features, such as easy-to-clean components and materials resistant to contamination, ensure that machines meet stringent hygiene standards. This is particularly important in the food industry to maintain product safety and quality.

Advanced Dough Handling: Innovations in dough handling technology, such as gentle dough forming and cutting mechanisms, help preserve the texture and consistency of biscuits. These advancements lead to a better-quality final product.

Integration with IoT and AI: The integration of Internet of Things (IoT) and Artificial Intelligence (AI) allows for predictive maintenance, process optimization, and better supply chain management. These technologies help in reducing downtime and improving overall operational efficiency.

Cost-Benefit Analysis for Small Businesses

Investing in a biscuit manufacturing machine can be a significant decision for small businesses. Below is a cost-benefit analysis table to help small business owners understand the financial implications and potential benefits:

| Factors | Cost | Benefit |

| Initial Investment | High initial cost for purchasing | Long-term savings on labor and increased production capacity |

| Operational Costs | Maintenance, energy consumption | Lowered operational costs with energy-efficient models |

| Labor Costs | Reduced need for manual labor | Savings on wages and associated labor costs |

| Production Efficiency | Training and integration time | Increased production speed and consistency |

| Product Quality | Investment in high-quality machinery | Superior product quality, leading to higher customer satisfaction and potential market growth |

| Market Competitiveness | Potentially high upfront cost | Enhanced ability to compete with larger manufacturers due to advanced technology and improved product offerings |

| Flexibility and Adaptability | Costs associated with machine versatility | Ability to quickly respond to market changes and demands |

For small businesses, the initial investment in a biscuit manufacturing machine may seem daunting, but the long-term benefits often outweigh the costs. Enhanced production capabilities, improved product quality, and operational efficiencies contribute to a stronger competitive position and potential for business growth.

Understanding Warranty and After-Sales Service

When investing in a biscuit manufacturing machine, understanding the warranty and after-sales service is paramount. The warranty serves as a guarantee of quality and performance, providing reassurance to manufacturers. Additionally, robust after-sales service ensures prompt resolution of any issues that may arise during the machine's lifespan.

A reputable manufacturer will offer a comprehensive warranty package, covering various components of the biscuit making machine. This typically includes coverage for mechanical parts, electrical components, and structural integrity. It's essential to carefully review the warranty terms to ascertain the duration of coverage and any exclusions that may apply.

Equally crucial is the after-sales service provided by the manufacturer or distributor. Timely maintenance and repair services are instrumental in maximizing the longevity and efficiency of the biscuit manufacturing machine. Manufacturers offering proactive after-sales support demonstrate their commitment to customer satisfaction and the seamless operation of their equipment.

Case Studies of Successful Implementations

To gain insights into the practical application of biscuit making machines, let's explore a few case studies showcasing successful implementations.

Case Study 1:

A leading biscuit manufacturer in Europe sought to enhance their production capabilities to meet growing demand. After thorough research, they invested in a state-of-the-art biscuit manufacturing machine equipped with advanced automation features. This investment not only increased their production capacity but also improved product consistency and quality.

Case Study 2:

In Asia, a startup biscuit company aimed to establish itself as a reputable player in the market. Understanding the importance of efficiency and cost-effectiveness, they opted for a compact yet efficient biscuit making machine. Despite budget constraints, the company achieved remarkable success by leveraging the machine's versatility to produce a diverse range of biscuit varieties.

Case Study 3:

A family-owned bakery in North America sought to modernize its operations while maintaining the artisanal quality of its products. They invested in a customizable biscuit manufacturing machine that allowed them to automate repetitive tasks without compromising on taste or texture. This strategic move not only increased their production capacity but also freed up time for innovation and product development.

These case studies exemplify the versatility and impact of biscuit making machines across different regions and business models. Whether it's streamlining production processes, ensuring consistency, or enabling expansion, the right machine can be a game-changer for biscuit manufacturers worldwide.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com