Everything you Need to Know About Biscuit Maker Machine

Introduction to Biscuit Maker Machine

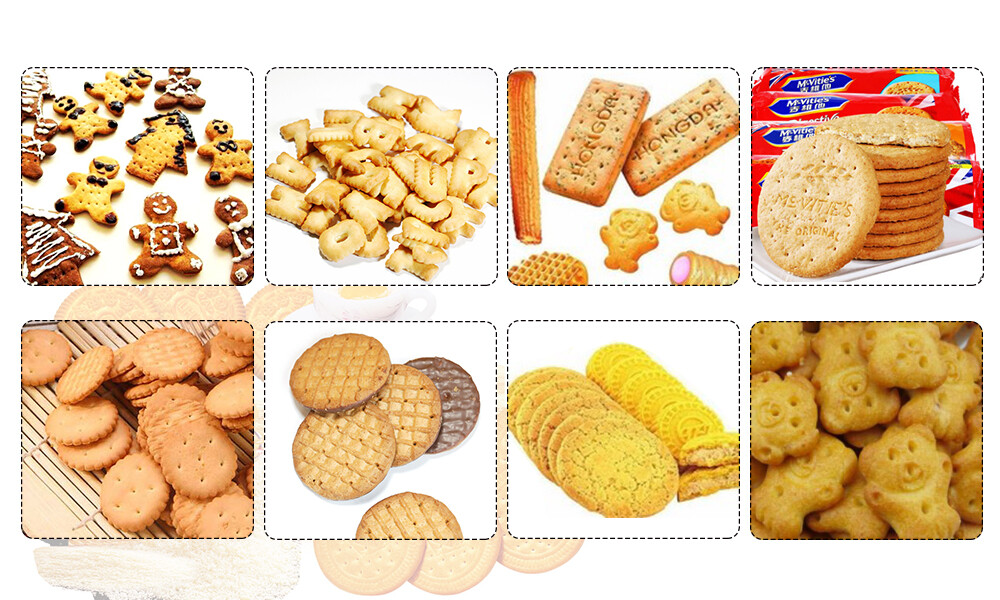

In the world of food processing equipment, the Biscuit Maker Machine stands out as an essential tool for both small bakeries and large-scale industrial operations. These machines are designed to automate the process of biscuit production, ensuring consistency, efficiency, and high-quality output. By utilizing advanced technology, Biscuit Maker Machines can handle various types of dough and produce biscuits of different shapes, sizes, and textures.

The main advantage of using a Biscuit Maker Machine is the significant reduction in manual labor, which not only speeds up the production process but also minimizes the risk of human error. Furthermore, these machines are equipped with features that allow precise control over baking parameters, resulting in perfectly baked biscuits every time. For businesses looking to expand their production capabilities, investing in a Biscuit Maker Machine is a wise decision that can lead to increased productivity and profitability.

Types of Biscuit Maker Machines

Biscuit Maker Machines come in various types, each designed to meet specific production needs. Understanding the differences between these machines can help you choose the right one for your business. Here are some common types of Biscuit Maker Machines:

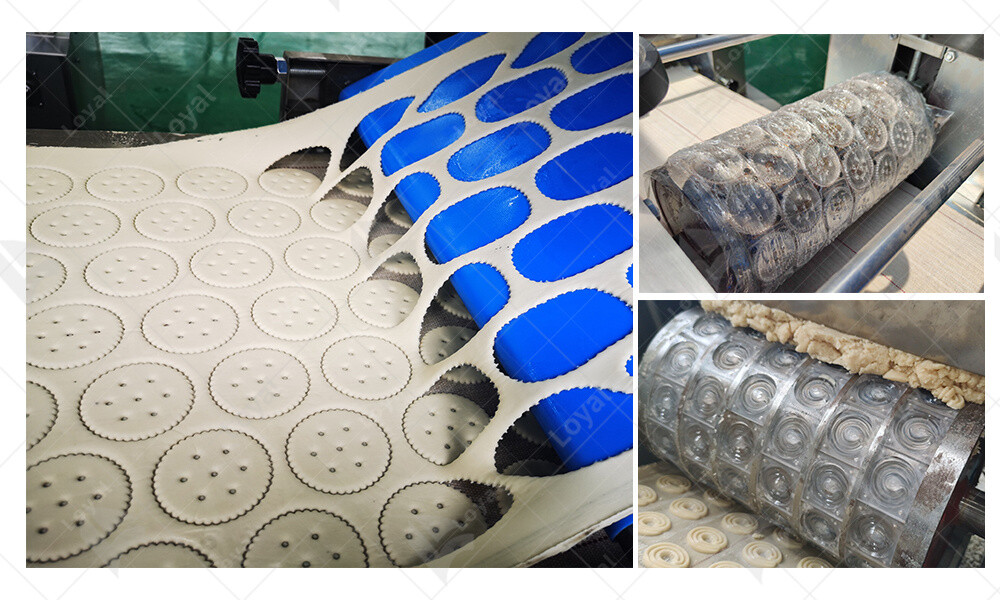

Rotary Moulding Machines: These machines are ideal for producing molded biscuits. They use a rotary molder to shape the dough into uniform biscuits. This type of machine is perfect for producing biscuits with intricate designs and patterns. It is highly efficient and capable of producing large quantities of biscuits in a short period.

Wire Cut Machines: Wire cut machines are designed for making biscuits from soft dough. They work by extruding the dough through a die, which is then cut into individual biscuits by a wire. This type of machine is versatile and can produce a wide range of biscuit shapes and sizes. Wire cut machines are known for their precision and consistency, making them a popular choice for many bakeries.

Depositor Machines: These machines are used for depositing dough directly onto baking trays. Depositor machines are particularly useful for producing biscuits with fillings or layered biscuits. They offer great flexibility in terms of the types of biscuits that can be produced and allow for easy adjustment of portion sizes.

Sandwiching Machines: For businesses that produce sandwich biscuits, sandwiching machines are essential. These machines automatically assemble biscuits with a filling in between, ensuring consistent and precise sandwiching. They are highly efficient and can significantly speed up the production process.

Key Features of Biscuit Maker Machines

| Feature | Description |

| Automation Level | Fully automated, semi-automated, or manual operation options |

| Production Capacity | Varies from small-scale (100 kg/h) to large-scale (1000 kg/h) |

| Material | Stainless steel construction for durability and hygiene |

| Baking System | Options include rotary ovens, tunnel ovens, and convection ovens |

| Moulds and Dies | Interchangeable moulds for different biscuit shapes and sizes |

| Control System | PLC control with touch screen interface for easy operation and monitoring |

| Energy Efficiency | Designed to minimize energy consumption while maintaining high productivity |

| Hygiene and Safety | Compliance with international food safety standards; easy to clean and maintain |

How Biscuit Maker Machines Work

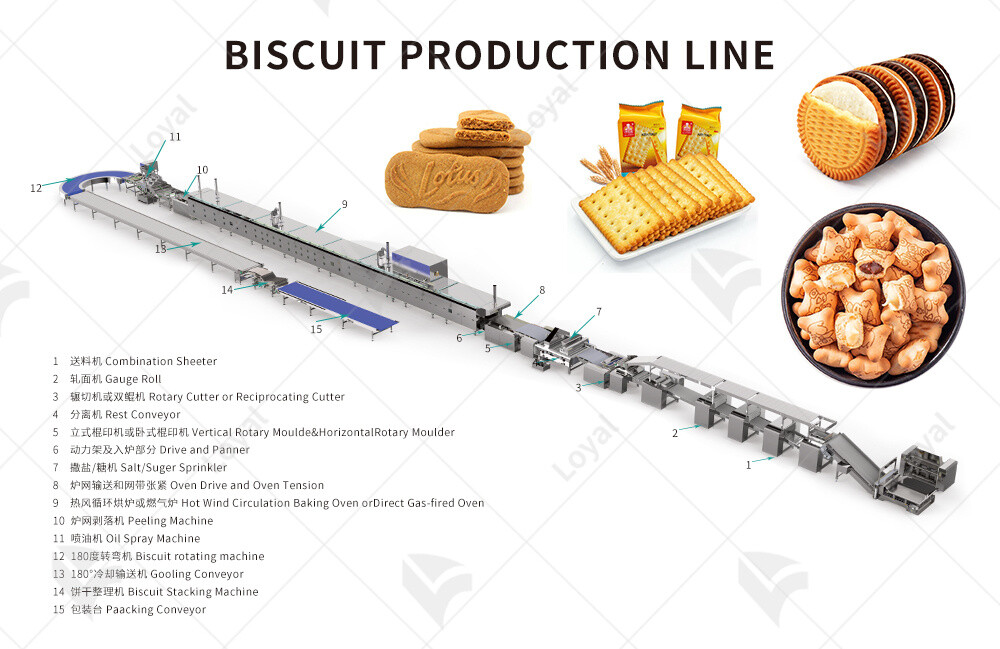

Biscuit maker machines operate through a series of coordinated steps that transform raw ingredients into finished biscuits. The process begins with the mixing of ingredients. In a typical setup, flour, sugar, fat, and other components are loaded into the mixer where they are blended into a homogeneous dough. The mixing time and speed are crucial for achieving the desired dough consistency.

After mixing, the dough is transferred to the forming section. This part of the machine utilizes moulds and dies to shape the dough into biscuits. The dough is extruded or stamped, creating uniform pieces that match the desired specifications. Advanced biscuit maker machines offer the flexibility to change moulds and dies quickly, allowing for the production of various biscuit shapes and sizes.

Next, the formed biscuits move to the baking stage. They are transported through an oven, which can be a rotary, tunnel, or convection type, depending on the machine's design. The baking process involves precise control of temperature and time to ensure even baking and optimal texture.

Finally, the baked biscuits enter the cooling and packaging phase. Proper cooling is essential to prevent moisture condensation, which can affect the biscuits' quality. Once cooled, the biscuits are packed using automated systems that ensure minimal handling, preserving hygiene and extending shelf life.

Advantages of Using Biscuit Maker Machines

| Advantage | Description |

| Consistency and Quality | Ensures uniform size, shape, and texture of biscuits |

| High Efficiency | Increases production speed, allowing for large-scale output |

| Labor Savings | Reduces the need for manual labor, lowering operational costs |

| Customization | Flexible design allows for the production of various biscuit types and shapes |

| Hygiene and Safety | Meets stringent food safety standards; minimizes contamination risks |

| Energy Efficiency | Advanced models are designed to use less energy, reducing operational costs |

| Ease of Use | User-friendly interfaces and automation simplify operation and monitoring |

| Reliability and Durability | Built with high-quality materials to ensure long-term, trouble-free operation |

Choosing the Right Biscuit Maker Machine

When selecting a Biscuit Maker Machine, it's crucial to consider several factors to ensure you choose the right one for your needs. Here's a table summarizing key features to look for:

| Feature | Description |

| Capacity | The amount of dough the machine can handle in one cycle. For large-scale production, look for higher capacities. |

| Automation Level | Fully automated machines reduce manual labor and increase efficiency. |

| Biscuit Types | Versatility in the types of biscuits the machine can produce, such as cookies, crackers, or shortbread. |

| Speed | Production speed in terms of biscuits per minute. Essential for meeting high demand. |

| Material | Stainless steel is preferred for durability and ease of cleaning. |

| Power Consumption | Energy efficiency to reduce operational costs. |

| Footprint | The size of the machine relative to your available space. |

| Safety Features | Includes guards and emergency stop buttons to ensure operator safety. |

| Maintenance Requirements | Ease of disassembly for cleaning and maintenance. |

| Cost | Consider the initial investment and potential return on investment. |

Maintenance Tips for Biscuit Maker Machines

Maintaining your Biscuit Maker Machine is essential for ensuring optimal performance and longevity. Regular maintenance can prevent unexpected breakdowns and extend the machine’s lifespan. Here are some critical maintenance tips:

Regular Cleaning: Keeping the Biscuit Maker Machine clean is paramount. After each use, ensure that all components, especially the dough hopper and the cutting blades, are thoroughly cleaned. Residue buildup can affect the machine's efficiency and the quality of the biscuits produced. Use appropriate cleaning agents recommended by the manufacturer and avoid abrasive materials that could damage the surfaces.

Lubrication: Regular lubrication of moving parts is necessary to keep the Biscuit Maker Machine running smoothly. Use food-grade lubricants to ensure there is no contamination of the biscuit dough. Check the manufacturer’s manual for specific lubrication points and recommended lubricants. Over-lubrication can attract dust and debris, so ensure you apply just the right amount.

Routine Inspections: Conduct routine inspections to identify wear and tear on parts such as belts, gears, and bearings. Replacing worn-out parts promptly can prevent larger, more expensive issues down the line. Keep a log of all inspections and maintenance activities to track the condition of the machine over time.

Calibration: Periodically check and calibrate the Biscuit Maker Machine to ensure it is operating at the correct settings. Incorrect calibration can lead to inconsistent biscuit sizes and shapes, affecting production quality. Follow the manufacturer’s guidelines for calibration procedures.

Troubleshooting Common Issues

Even with regular maintenance, Biscuit Maker Machines can encounter issues. Here are some common problems and their troubleshooting steps:

Uneven Biscuit Shapes: If the biscuits are coming out uneven or malformed, check the dough consistency first. Dough that is too dry or too wet can affect the shape. Also, inspect the dough hopper and cutting blades for any blockages or damage. Ensure the machine is properly calibrated and that the dough is being fed evenly.

Machine Jams: Frequent jams can be frustrating. These can often be traced back to dough consistency or foreign objects in the machine. Ensure that the dough does not contain any hard particles. Regularly clean and inspect the feeding mechanism to remove any obstructions. If jams persist, it might be necessary to adjust the settings or replace worn parts.

Inconsistent Baking: If the biscuits are baking inconsistently, it might be due to uneven dough thickness or incorrect machine settings. Check the rollers and cutters to ensure they are producing dough of uniform thickness. Additionally, verify that the oven settings are correct and consistent with the biscuit type being produced.

Electrical Issues: Electrical problems can halt production and may pose safety risks. If the machine fails to start or suddenly stops, check for blown fuses or tripped breakers. Inspect the wiring and connections for any signs of wear or damage. It’s advisable to have a qualified technician handle any electrical repairs to ensure safety and compliance with industry standards.

Innovations in Biscuit Maker Technology

The Biscuit Maker Machine has undergone significant advancements in recent years, driven by the need for higher efficiency, improved quality, and greater versatility. One of the most notable innovations is the integration of automated control systems. These systems enable precise regulation of baking times and temperatures, ensuring consistent quality and reducing human error. Additionally, modern biscuit makers are equipped with smart sensors that monitor the dough consistency and adjust the process in real-time, which results in a uniform product every batch.

Another major innovation is the introduction of multi-functional machines. These machines can produce a variety of biscuit types, from traditional cookies to more complex filled and shaped biscuits. This versatility is achieved through interchangeable molds and advanced extrusion technologies. By using such machines, manufacturers can diversify their product lines without significant additional investment.

Energy efficiency is also a key focus area in recent innovations. Newer models of biscuit maker machines are designed to minimize energy consumption through better insulation and optimized heating elements. This not only lowers operational costs but also aligns with growing environmental sustainability goals.

Furthermore, advancements in hygienic design have improved the cleanability of biscuit maker machines. Enhanced designs with smooth surfaces and fewer crevices reduce the risk of contamination and make it easier to maintain strict hygiene standards, which is crucial in food production.

Best Practices for Biscuit Production

Effective biscuit production hinges on the adherence to best practices that optimize the performance of the biscuit maker machine while ensuring the highest quality product. One critical practice is the regular calibration and maintenance of the equipment. Regular checks and calibrations ensure that the machine operates within the desired parameters, which is essential for maintaining consistency in biscuit size, shape, and texture.

Another best practice involves ingredient quality control. Using high-quality ingredients with consistent properties is vital. Variations in flour, sugar, and fat content can significantly affect the dough's behavior and, consequently,

the quality of the biscuits. Implementing strict quality control measures and working closely with suppliers to ensure ingredient consistency can help mitigate these issues.

Proper dough preparation is also crucial for optimal biscuit production. The dough should be mixed thoroughly to ensure uniformity and avoid overmixing, which can lead to undesirable textures. Monitoring the temperature and humidity levels during mixing and resting stages can significantly impact the final product's quality.

Lastly, training and development of personnel operating the biscuit maker machine is a best practice that cannot be overlooked. Well-trained operators are better equipped to handle the machine, troubleshoot issues, and maintain the equipment properly. Continuous training programs and staying updated with the latest technological advancements in biscuit making can lead to more efficient operations and better-quality products.

Conclusion

Biscuit Maker Machines** are a vital component in modern biscuit production, offering efficiency, consistency, and high-quality output. Understanding the different types and key features of these machines helps in selecting the right model to suit specific production needs. By comprehending how these machines work and the advantages they provide, manufacturers can leverage their full potential.

Regular maintenance and timely troubleshooting are crucial for ensuring uninterrupted operation and longevity. Keeping abreast of innovations in biscuit maker technology and adhering to best practices can further enhance production efficiency and product quality. By integrating these insights, businesses can optimize their biscuit production processes and maintain a competitive edge in the market.

References

1.Baker Perkins - www.bakerperkins.com

2.GEA Group - www.gea.com

3.Bühler Group - www.buhlergroup.com

4.Reading Bakery Systems - www.readingbakery.com

5.Haas-Meincke (part of Bühler Group) - www.haas.com