Everything you need to know about baby food machine In 2024

Introduction

In 2024, the landscape of industrial food machinery, particularly in the realm of baby food production, has witnessed remarkable advancements. This article serves as a comprehensive guide to navigate through the intricacies of baby food machines, addressing their functionalities, technological innovations, and market trends.

With the growing demand for safe, nutritious, and convenient baby food products, manufacturers are continually refining their processes and technologies. Among these innovations, the baby food machine stands out as a pivotal tool in ensuring the production of high-quality infant nutrition.

The evolution of baby food machines

In the realm of industrial food processing, the evolution of baby food machines stands as a testament to technological advancement and consumer demand. Since their inception, these machines have undergone significant transformations to meet the ever-changing needs of parents and caregivers worldwide.

Early iterations of baby food machines were rudimentary, primarily serving to puree or grind cooked fruits and vegetables into a more digestible form for infants. However, with advancements in technology and a growing emphasis on nutrition and convenience, the landscape of baby food machines has evolved dramatically.

One of the most notable advancements in recent years is the integration of smart technology into baby food machines. Manufacturers have recognized the importance of convenience for busy parents and have developed machines equipped with features such as automatic blending, steaming, and sterilizing capabilities. These smart machines not only streamline the baby food preparation process but also ensure optimal nutrition and safety for infants.

Moreover, sustainability has become a focal point in the design and manufacturing of baby food machines. With increasing awareness of environmental issues, consumers are seeking eco-friendly alternatives in all aspects of their lives, including baby care products. As a result, manufacturers have begun incorporating sustainable materials and energy-efficient processes into the production of baby food machines, aligning with the global push for a greener future.

Another significant evolution in baby food machines is the expansion of product offerings to cater to diverse dietary preferences and requirements. From traditional purees to organic blends and allergen-free options, manufacturers have diversified their product lines to accommodate the varying needs of modern families. This inclusivity reflects a broader societal shift towards health-conscious consumption and the recognition of individual dietary needs from an early age.

In conclusion, the evolution of baby food machines in 2024 is characterized by technological innovation, sustainability, and diversity. As these machines continue to adapt to the changing demands of consumers, they play an indispensable role in simplifying the process of infant nutrition while prioritizing safety, convenience, and environmental responsibility.

Components of a Baby Food Maker

Component | Description |

Blending System | The blending system consists of high-speed blades or mixing paddles responsible for homogenizing and emulsifying various ingredients into a smooth baby food puree. It ensures uniform texture and consistency throughout the product. |

Steam Cooking Unit | The steam cooking unit is essential for cooking or steaming fruits, vegetables, and other ingredients before blending. It utilizes controlled steam to soften and sterilize raw materials, enhancing food safety and digestibility for infants. |

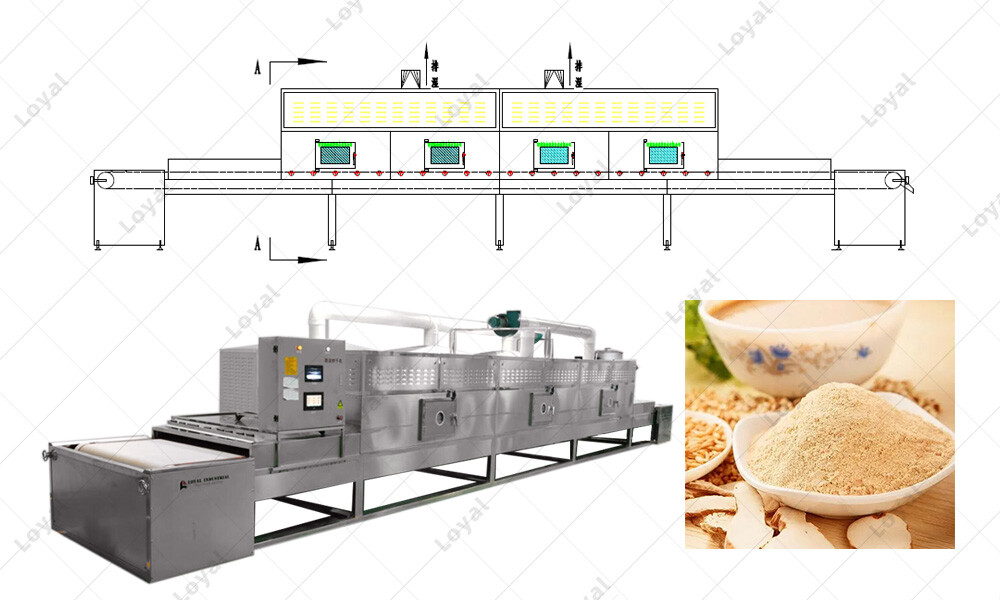

Grinding Mechanism | The grinding mechanism incorporates precision grinding or milling components to reduce solid ingredients into fine particles or powders. It facilitates the processing of hard or fibrous foods, such as grains, meats, and nuts, into suitable textures for baby consumption. |

Sterilization System | The sterilization system employs heat treatment or pasteurization techniques to eliminate harmful bacteria, enzymes, and microorganisms present in raw materials or processing equipment. It ensures the microbiological safety and shelf stability of the final baby food products. |

Control Panel | The control panel serves as the central interface for operating and monitoring the baby food machine. It allows operators to adjust processing parameters, such as blending speed, cooking temperature, and sterilization time, to meet specific product requirements and quality standards. |

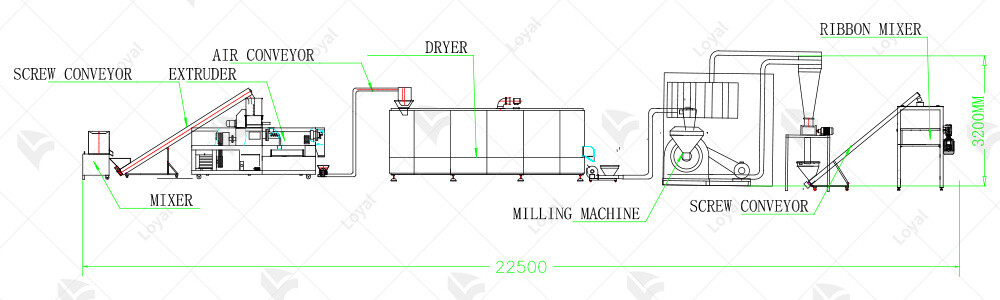

Material Handling System | The material handling system includes conveyors, hoppers, and feeders responsible for transferring raw ingredients, additives, and packaging materials throughout the production process. It ensures efficient workflow and minimizes manual handling, reducing the risk of contamination and labor costs. |

Quality Assurance Sensors | Quality assurance sensors, such as temperature probes, pressure gauges, and moisture detectors, are integrated into the baby food machine to monitor critical process parameters and product characteristics in real-time. They enable continuous quality control and corrective actions to maintain product consistency and safety. |

Advantages of a Baby Food Maker

As industrial food machinery experts, we recognize the significant advantages offered by modern baby food machines. In 2024, these innovative appliances continue to revolutionize the production of nutritious and convenient baby food products.

1. Precision and Consistency

One of the primary advantages of utilizing a baby food maker lies in its ability to ensure precision and consistency in food processing. These machines are equipped with advanced technology that enables them to precisely measure and mix ingredients according to predetermined formulas. This results in consistent texture, taste, and nutritional content in every batch of baby food produced.

2. Efficiency and Productivity

In today's fast-paced industrial environment, efficiency is paramount. Baby food machines are designed to streamline the production process, significantly enhancing productivity. With automated functions and optimized workflows, these machines can produce large quantities of baby food in a relatively short amount of time, meeting the demands of both manufacturers and consumers.

3. Nutritional Integrity

Maintaining the nutritional integrity of baby food is crucial for promoting infant health and development. Baby food makers employ cutting-edge technology to preserve the nutritional value of ingredients throughout the processing stages. From steaming and pureeing to packaging, these machines ensure that essential vitamins, minerals, and nutrients are retained, providing infants with wholesome and nourishing food options.

4. Versatility and Customization

Another notable advantage of baby food machines is their versatility and customization capabilities. Manufacturers can easily adjust settings and parameters to produce various types of baby food, catering to different dietary preferences and requirements. Whether it's smooth purees, textured blends, or organic options, these machines offer flexibility to meet diverse consumer needs.

5. Hygiene and Safety

Ensuring the highest standards of hygiene and safety is non-negotiable in the food industry, especially when it comes to infant nutrition. Baby food makers are engineered with robust sanitation features, including stainless steel surfaces, automated cleaning cycles, and stringent quality control measures. These safeguards minimize the risk of contamination and ensure that every batch of baby food is safe for consumption.

Technological Advances

The baby food industry has witnessed a remarkable transformation in 2024, largely attributed to groundbreaking technological advancements in baby food machines. These machines, equipped with state-of-the-art features and capabilities, have streamlined production processes, ensuring the delivery of safe and nutritious products to consumers worldwide.

One notable technological advance in baby food machines is the integration of smart automation systems. These systems leverage artificial intelligence and machine learning algorithms to optimize various stages of production, from ingredient mixing to packaging. By automating repetitive tasks and minimizing human intervention, manufacturers can significantly increase efficiency while reducing the risk of errors or contamination.

Moreover, the incorporation of advanced sensors and monitoring devices has revolutionized quality control measures in baby food production. These sensors enable real-time monitoring of key parameters such as temperature, moisture levels, and microbial activity, ensuring adherence to strict safety standards throughout the manufacturing process. Any deviations from preset parameters can be promptly detected and addressed, preventing the production of substandard or unsafe products.

Another notable advancement is the development of precision dosing technologies. Modern baby food machines are equipped with highly accurate dosing systems that can dispense ingredients with unparalleled precision. This level of accuracy not only ensures consistency in product formulation but also minimizes wastage and optimizes resource utilization.

Furthermore, advancements in material science have led to the development of innovative packaging solutions for baby food products. Packaging materials with enhanced barrier properties can now better preserve the freshness and nutritional content of infant foods, extending their shelf life without the need for preservatives or additives.

Operational Precautions

As industrial food machinery experts, we understand the critical importance of operational precautions when it comes to utilizing baby food machines in 2024. These advanced machines have revolutionized the production of infant nutrition, offering efficiency and consistency. However, their optimal performance relies heavily on adherence to operational guidelines and safety measures.

1. Regular Maintenance Checks

Regular maintenance is paramount to ensure the seamless operation of baby food machines. Before each use, thorough inspections should be conducted to identify any signs of wear and tear, loose components, or potential hazards. This includes inspecting conveyor belts, blades, and any moving parts for damage or malfunction.

2. Sanitization Protocols

Maintaining hygiene standards is non-negotiable in the production of baby food. All components of the machine that come into contact with food must be sanitized before and after each use. This includes disassembling parts if necessary and employing food-grade cleaning agents to eliminate any bacteria or contaminants.

3. Temperature Control

Precise temperature control is essential to preserve the nutritional integrity of baby food products. Operators must monitor temperature settings closely, ensuring they align with recommended guidelines for different food types. Regular calibration of temperature sensors and heaters is necessary to prevent overheating or undercooking, which could compromise product quality and safety.

4. Emergency Shutdown Procedures

In the event of an unexpected malfunction or safety breach, operators should be trained in emergency shutdown procedures. This may involve cutting off power to the machine, activating safety locks, or implementing manual overrides to halt operations immediately. Prompt action during emergencies can prevent potential hazards and protect both equipment and personnel.

5. Staff Training and Supervision

Proper training and supervision of personnel operating baby food machines are paramount. Operators should undergo comprehensive training programs covering equipment operation, safety protocols, and emergency procedures. Regular refresher courses should be provided to ensure that staff remain up-to-date with the latest industry standards and best practices.

Market Trends and Future Outlook

With the rapid advancement in technology and changing consumer preferences, the market for baby food machines has witnessed significant trends and is poised for further evolution in the coming years. Let's delve into the current market trends and explore the future outlook for baby food machines in 2024.

As industrial food machinery experts, we recognize the importance of staying abreast of market dynamics to anticipate future trends and cater to evolving consumer demands effectively.

In recent years, the demand for baby food machines has surged, driven by several factors such as increasing awareness regarding the importance of nutrition for infants, rising disposable incomes, and the convenience offered by automated food preparation solutions.

One prominent trend in the market is the growing preference for multifunctional baby food machines. Consumers seek versatility in these machines, which can not only puree fruits and vegetables but also steam, blend, and even sterilize bottles, offering comprehensive solutions for infant nutrition.

Moreover, there is a noticeable shift towards smart baby food machines equipped with IoT capabilities. These intelligent machines can be controlled remotely via smartphones, allowing parents to monitor and adjust the food preparation process conveniently. Integration with recipe apps and personalized nutrition recommendations further enhances the appeal of such devices.

Another key trend shaping the market is the emphasis on sustainability. With increasing environmental concerns, consumers are gravitating towards eco-friendly baby food machines that minimize waste generation and energy consumption. Manufacturers are responding by incorporating recyclable materials, optimizing energy efficiency, and adopting sustainable production practices.

Looking ahead to the future, the baby food machine market is poised for continued growth and innovation. Technological advancements, particularly in areas such as artificial intelligence and machine learning, are expected to drive product innovation, enabling more precise customization of food textures and nutritional profiles to meet individual infant needs.

Furthermore, as the global population continues to urbanize and lead increasingly fast-paced lifestyles, the demand for convenient and time-saving solutions for infant nutrition will only intensify. This presents opportunities for manufacturers to develop compact, user-friendly baby food machines that cater to the needs of busy parents without compromising on nutritional quality.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)