Enhancing Pasta Quality: High-Efficiency Additives Microwave Sterilization Machine Unleashed

Enhancing Pasta Quality: High-Efficiency Additives Microwave Sterilization Machine Unleashed

Introduction

Our company leverages cutting-edge technologies from Ispecc and Püschner to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Ispecc and Püschner, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

Current Challenges in Pasta Sterilization

An analysis of existing challenges and limitations in traditional pasta sterilization methods sets the stage for understanding the evolving landscape of pasta production. Traditional methods, while effective, pose challenges in terms of time consumption and maintaining optimal product quality. The need for innovation and efficiency improvement in pasta production becomes evident as consumer demands evolve, emphasizing the importance of delivering high-quality pasta products in a timely manner.

This section delves into the intricacies of traditional sterilization methods, highlighting the shortcomings that have prompted the exploration of advanced technologies. Challenges such as prolonged processing times, potential flavor and texture alterations, and energy inefficiencies are discussed. As the pasta industry faces these hurdles, the narrative naturally transitions to the innovative solutions offered by technologies like the Additives Microwave Sterilization Machine.

The identification of challenges acts as a catalyst for the subsequent exploration of advanced sterilization methods. By addressing these challenges head-on, the article aims to showcase how technologies like the Additives Microwave Sterilization Machine play a pivotal role in overcoming the limitations of traditional methods, ultimately contributing to a more efficient and quality-driven pasta production process.

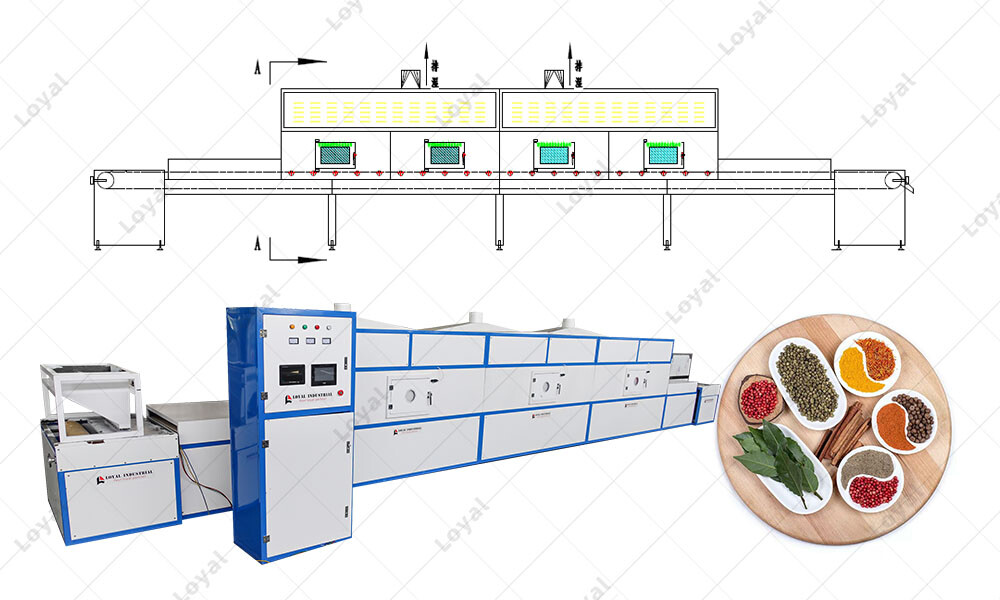

Unveiling Additives Microwave Sterilization Technology

This section delves into the intricate principles and mechanisms that define the Additives Microwave Sterilization Machine, revealing its uniqueness and advantages over conventional sterilization methods. The exploration begins by providing a comprehensive understanding of how this cutting-edge technology operates and sets itself apart from traditional approaches.

The narrative emphasizes the alignment of Additives Microwave Sterilization with the overarching goals of the pasta production industry: enhancing efficiency and maintaining high product quality. A detailed examination of the technology's features, including precision, speed, and overall efficiency in the sterilization process, unfolds. The section aims to convey not only the technical aspects but also the practical implications of adopting this innovative approach in pasta production.

Technological Features of High-Efficiency Additives Microwave Sterilization Machine

A comprehensive overview highlights the technological features that define a high-efficiency Additives Microwave Sterilization Machine. Emphasis is placed on precision, speed, and overall efficiency in the sterilization process, illustrating how automation contributes to elevating efficiency in pasta production.

Real-world Applications and Success Stories

Illustrating the practical applications of high-efficiency Additives Microwave Sterilization Machine through case studies and testimonials, this section provides a testament to its transformative impact on pasta production. By delving into real-world scenarios, we aim to showcase the tangible improvements in efficiency, quality, and overall pasta processing achieved by businesses that have embraced this technology.

We present detailed case studies highlighting how pasta producers have successfully implemented high-efficiency Additives Microwave Sterilization. These cases delve into specific challenges faced by the industry and how the technology addressed them. Bold outcomes such as increased production capacity, reduced processing time, and enhanced overall quality are spotlighted.

Direct testimonials from industry leaders who have adopted Additives Microwave Sterilization add a human touch to the narrative. These testimonials not only provide insights into the decision-making process behind adopting this technology but also emphasize its positive impact on various facets of pasta production.

Backing these narratives with quantifiable data is essential. We explore key performance indicators that reflect the improvements brought about by high-efficiency Additives Microwave Sterilization. Whether it's a percentage increase in production efficiency, a reduction in resource utilization, or an improvement in the final product's quality, we aim to provide concrete evidence of the technology's success.

Future Trends and Innovations

Anticipated trends in the continued application of high-efficiency Additives Microwave Sterilization are explored, along with innovations on the horizon that could further enhance efficiency and sustainability in pasta processing. The role of technology in shaping the future of the pasta production industry is examined.

Conclusion

Summarizing key points, the conclusion emphasizes the impact of high-efficiency Additives Microwave Sterilization on pasta production efficiency. Businesses are encouraged to adopt innovative technologies for enhanced quality, efficiency, and safety, with a forward-looking perspective on the ongoing evolution of sterilization practices in the pasta production industry.

Common Questions About Additives Microwave Sterilization Machine

How does Additives Microwave Sterilization differ from traditional sterilization methods?

Additives Microwave Sterilization employs microwave technology, offering a faster and more precise sterilization process compared to traditional methods. It ensures improved product quality, taste, and nutritional value.

What makes a High-Efficiency Additives Microwave Sterilization Machine stand out?

The high-efficiency machine is designed for precision, speed, and overall process efficiency. Its technological features elevate the sterilization process, contributing to enhanced quality and reduced processing time.

Are there real-world examples of successful applications?

Yes, numerous businesses have experienced success with the Additives Microwave Sterilization Machine. Case studies and testimonials demonstrate quantifiable improvements in efficiency, quality, and overall pasta processing.

How does this technology contribute to regulatory compliance and safety standards?

The machine ensures compliance with industry regulations and safety standards. Its automated features and precision contribute to meeting and exceeding regulatory requirements, promoting a safer pasta production environment.

What challenges might businesses face during the implementation of this technology?

Challenges may include initial setup and integration into existing processes. However, effective solutions and strategies are provided to facilitate a smooth implementation process in pasta production facilities.

How does high-efficiency Additives Microwave Sterilization impact the preservation of pasta flavor and texture?

The technology preserves the flavor and texture of pasta products by ensuring a precise and controlled sterilization process. This contributes to maintaining the overall quality and sensory characteristics of the final product.

What are the anticipated future trends in Additives Microwave Sterilization technology?

The article explores anticipated trends, including further enhancements in efficiency and sustainability. Ongoing innovations are expected to shape the future of the pasta production industry, driven by advancements in sterilization practices.

In conclusion, these FAQs provide valuable insights into the world of Additives Microwave Sterilization Machines, addressing common questions and offering a comprehensive understanding of the technology's benefits and applications in the pasta production industry.