Elevating Spice Processing: Full Automation and High Efficiency in Microwave Spices Sterilizer Machine

Introduction

Our company leverages cutting-edge technologies from Ispecc and Püschner to develop a state-of-the-art microwave sterilization technique. By drawing inspiration from the advanced methodologies employed by Ispecc and Püschner, we have successfully integrated their innovative approaches into our manufacturing process. This collaborative effort ensures that our microwave sterilization technology meets the highest industry standards, providing an effective and efficient solution for eliminating harmful microorganisms. Through continuous refinement and adaptation of these proven techniques, our company remains at the forefront of technological advancements in the field, delivering products that prioritize both safety and quality.

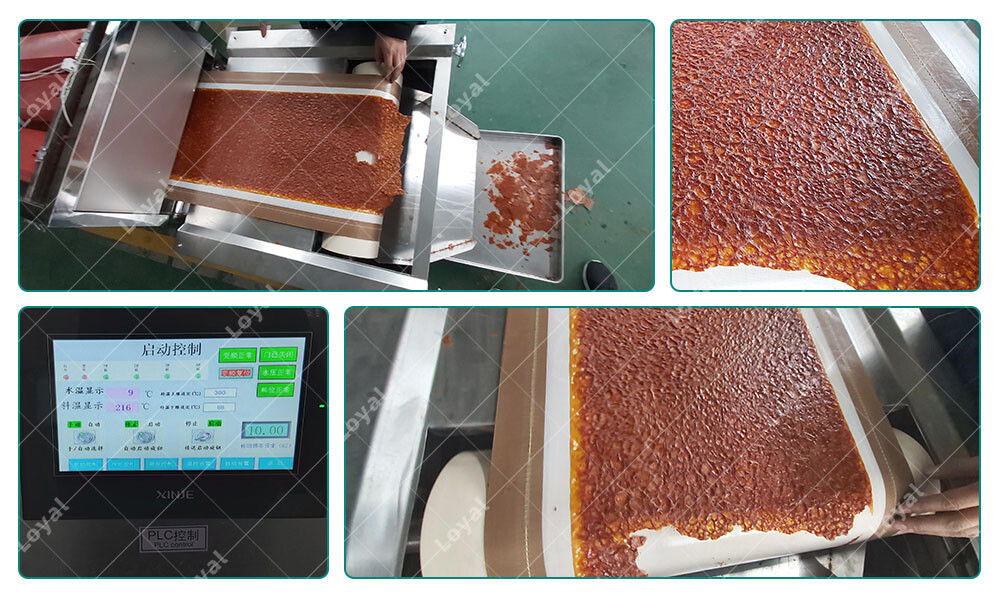

Full Automation in Microwave Spices Sterilizer Machine

Microwave Spices Sterilizer Machine incorporates cutting-edge Full Automation features. This ensures seamless operation throughout the spice sterilization process, from loading to unloading. Automation mitigates the risk of human error and guarantees consistent, high-quality spice processing.

The benefits extend beyond operational efficiency. Automated processes significantly enhance overall spice product quality by maintaining optimal sterilization conditions consistently. This reduces the likelihood of contamination, meeting the stringent standards set by the spice industry.

High Efficiency for Enhanced Spice Processing

The technological components contributing to the high efficiency of Microwave Spices Sterilizer Machine will be explored. Advanced heating mechanisms, real-time monitoring, and adaptive control systems collectively optimize spice sterilization efficiency.

The high efficiency directly translates into accelerated spice sterilization processes without compromising precision. This section will provide insights into how this technology achieves both speed and accuracy, crucial factors in the spice industry.

Real-world case studies will be presented to illustrate the tangible efficiency gains witnessed by industries adopting Microwave Spices Sterilizer Machine. These examples will showcase the technology's practical application and its transformative impact on spice processing.

Technological Advancements in Spice Sterilization

This section will provide a comprehensive overview of the cutting-edge technologies embedded in Microwave Spices Sterilizer Machine. Frequency modulation, adaptive control systems, and other innovations contribute to the equipment's efficiency and reliability, ensuring it stays at the forefront of spice sterilization technology.

The incorporation of smart systems sets Microwave Spices Sterilizer Machine apart. From IoT-enabled monitoring to adaptive learning algorithms, these smart features optimize performance, ensuring precise spice sterilization tailored to specific products. Industry experts recognize the significance of these integrations in achieving consistent quality.

Anticipating the future is essential in the rapidly advancing field of spice sterilization. This part of the article will explore emerging trends and innovations, providing insights into what the future holds for Microwave Spices Sterilizer Machine.

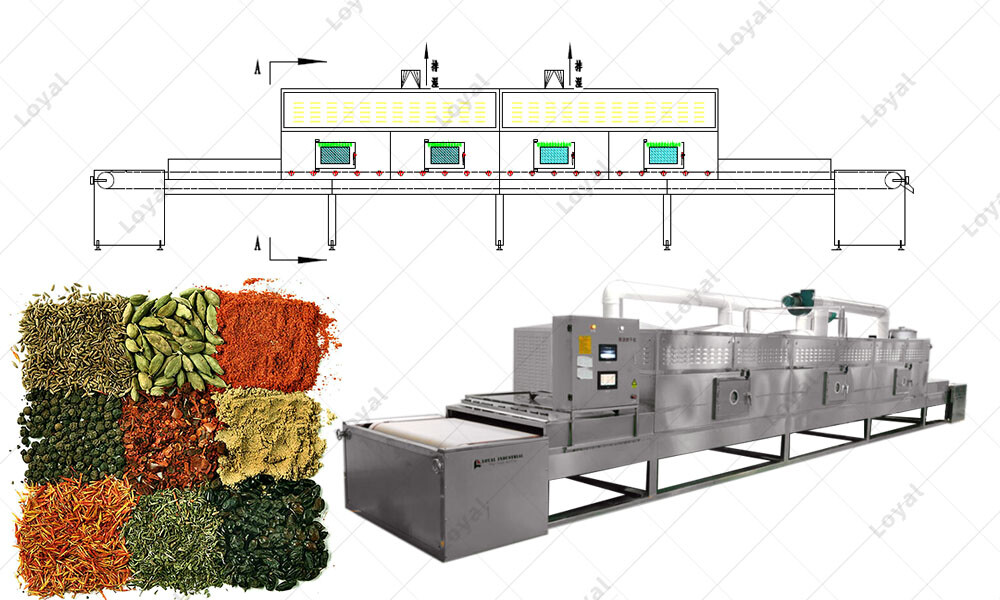

Applications in Spice Industry

The versatility of Microwave Spices Sterilizer Machine extends across various applications in the spice industry. This section will explore how this technology is employed in sterilizing a wide range of spice products, including powders, seeds, and blends, showcasing its adaptability and impact on different sectors.

Different industries within the spice sector stand to gain significantly from the integration of Full Automation and High Efficiency in Microwave Spices Sterilizer Machine. Real-world examples and testimonials from relevant industries will be presented to validate the positive impact of this technology on their processes.

This section will highlight real-world examples where Microwave Spices Sterilizer Machine has been successfully implemented. These examples will serve as a testament to the practical advantages and positive outcomes experienced by companies embracing this innovative sterilization solution.

Environmental Impact and Energy Efficiency

This section will delve into the environmentally friendly aspects of Microwave Spices Sterilizer Machine. Its reduced water usage, lower energy consumption, and overall sustainability will be discussed, aligning with green practices and the increasing importance of eco-friendly solutions in the spice processing industry.

Exploration of the energy efficiency measures incorporated in Microwave Spices Sterilizer Machine will highlight its commitment to reducing environmental impact. Additionally, sustainable practices, such as the use of renewable energy sources, will be discussed to emphasize the equipment's dedication to environmental responsibility.

A comparative analysis will be conducted to juxtapose the environmental impact of Microwave Spices Sterilizer Machine with other traditional spice sterilization methods. Scientific data and authoritative opinions will be referenced to provide a comprehensive understanding of the technology's ecological advantages.

Challenges and Solutions

Anticipating challenges, including technical limitations and regulatory considerations, is crucial. This part will provide an insightful examination of the potential obstacles faced when implementing Microwave Spices Sterilizer Machine in the spice industry.

To maintain a balanced perspective, viable strategies and solutions will be presented to address the identified challenges. Expert opinions and industry best practices will be incorporated to ensure the credibility and practicality of the proposed solutions.

Microwave Spices Sterilizer Machine is not static; it undergoes continuous improvement. This segment will discuss how manufacturers actively engage in refining the design and functionality of the equipment to stay ahead of challenges and meet evolving industry demands.

Conclusion

In conclusion, the exploration of Microwave Spices Sterilizer Machine has illuminated a revolutionary path in spice processing. Through full automation and high efficiency, this technology addresses the challenges faced by the spice industry, ensuring elevated standards in quality, safety, and sustainability.

Recapping the key advantages discussed throughout this article, the integration of full automation not only streamlines spice processing but also guarantees consistent, high-quality sterilization. The high efficiency achieved by Microwave Spices Sterilizer Machine not only accelerates the sterilization process but also enhances precision, crucial factors in meeting the stringent standards of the spice industry.

Looking ahead, the future outlook for Microwave Spices Sterilizer Machine appears promising, with ongoing technological advancements, integration of smart systems, and emerging trends ensuring its continued relevance. This calls for a collective call to action within the spice industry to embrace these advanced sterilization technologies, paving the way for a more efficient, sustainable, and innovative future.

In summary, the marriage of full automation and high efficiency in Microwave Spices Sterilizer Machine heralds a new era in spice processing, setting a benchmark for the industry to follow.

more efficient and sustainable spice industry.