Discover The Secret To Perfect nutrition bar equipment: nutrition bar equipment Recipes

Introduction

The snack industry has evolved significantly over the past few decades, driven by shifting consumer preferences, technological advancements, and the growing demand for convenience. Historically, snack foods were often viewed as unhealthy, but recent trends show a major transformation in this perception. Today, health-conscious consumers are increasingly seeking nutritious options that fit into their busy lifestyles, making snacks like granola bars, protein bars, and energy bars essential components of modern diets.

In response to this growing demand, the food manufacturing industry has been focusing on improving production methods. This is where fully automatic nutrition bar equipment comes into play. The introduction of automated systems for the production of nutrition bars is transforming the snack industry, offering faster, more efficient, and cost-effective production methods. Fully automatic nutrition bar equipment such as the nutrition bar production line, nutrition bar manufacturing machine, and nutrition bar equipment have revolutionized the way nutrition bars are produced, ensuring consistency, quality, and sustainability.

This article delves into how fully automatic nutrition bar equipment is changing the landscape of the snack industry. We will explore the components of these automated systems, the benefits they offer, and the ways in which they are reshaping both production efficiency and product quality. As we move forward, we will also discuss the role of automation in addressing consumer demand for healthier snack options while reducing costs and increasing production speed.

What is Fully Automatic Nutrition Bar Equipment?

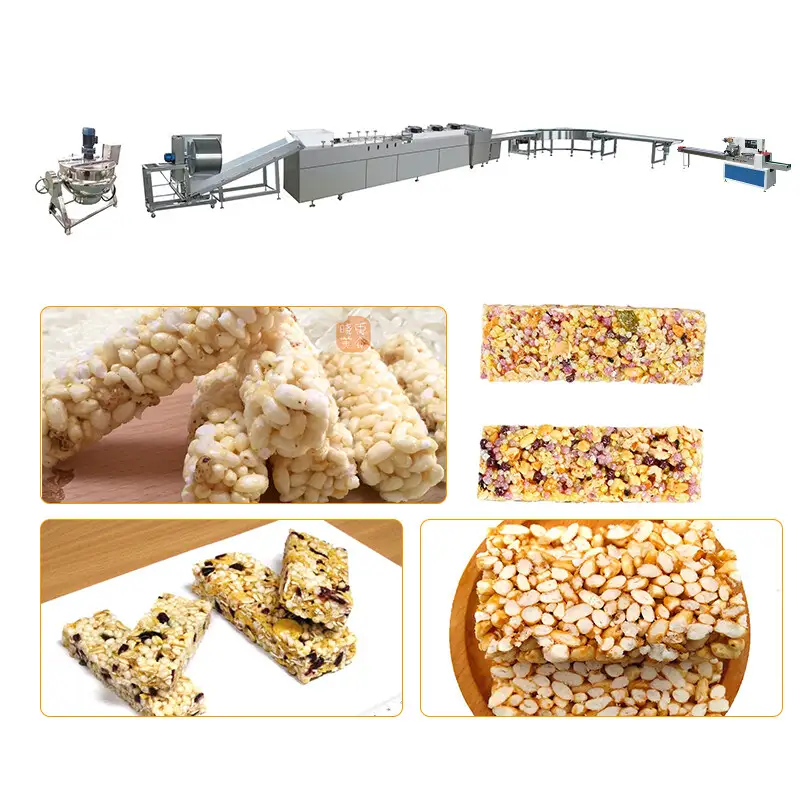

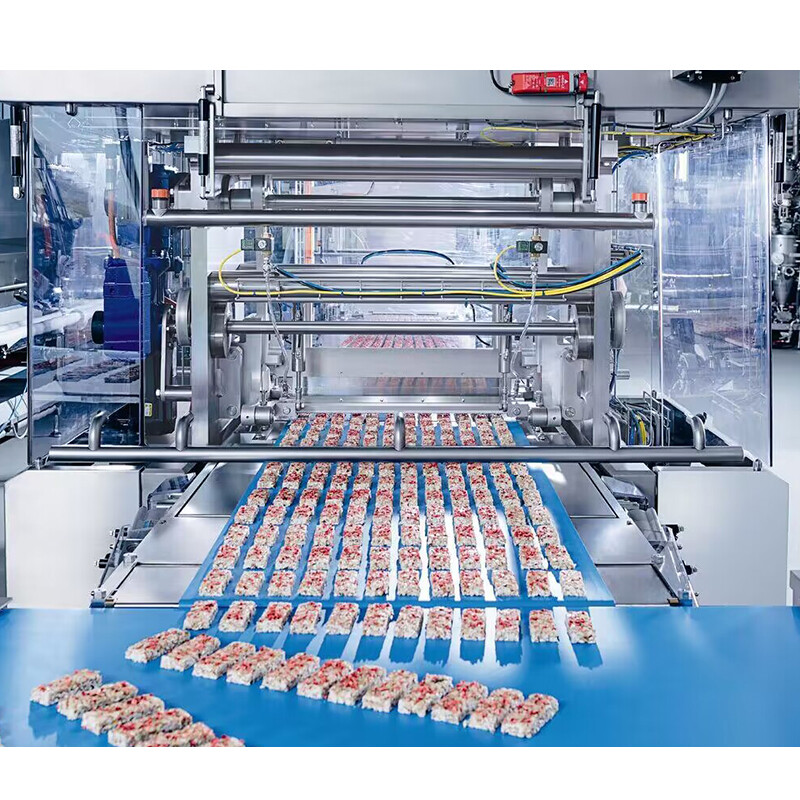

Fully automatic nutrition bar equipment refers to a complete set of machinery designed to streamline and automate the production of nutrition bars. This equipment includes systems for mixing ingredients, shaping bars, cutting, cooling, and packaging, all controlled by advanced automation technology. The nutrition bar production line is designed to efficiently process large batches of ingredients into finished bars with minimal human intervention.

At the heart of the fully automated system is the nutrition bar manufacturing machine, which plays a crucial role in transforming raw ingredients into uniform, high-quality nutrition bars. These machines are engineered with precision to ensure that each batch meets the desired specifications in terms of size, shape, texture, and flavor. The nutrition bar equipment integrates various stages of the production process, from ingredient mixing and extrusion to the cutting, shaping, and cooling of the bars.

Key Features of Fully Automatic Nutrition Bar Equipment:

Precision Control: Advanced sensors and controllers ensure precise ingredient measurement and consistent mixing.

Automated Ingredient Mixing: The system automatically blends the selected ingredients such as oats, nuts, protein powder, and sweeteners, ensuring uniform consistency across every batch.

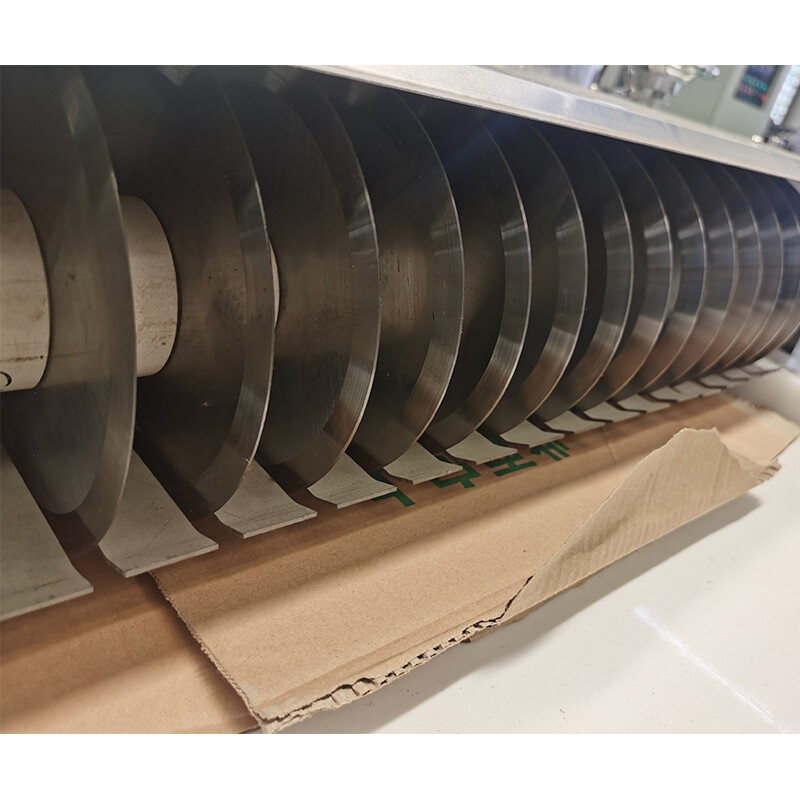

Efficient Shaping and Cutting: The manufacturing machine automatically shapes and cuts the bars to the desired size and form, reducing labor and ensuring uniformity.

Cooling: A fully integrated system takes care of the drying process, followed by cooling to ensure the bars maintain the correct texture.

Packaging : The final step involves packaging the bars in a hygienic, efficient manner, all performed by automated systems, reducing the need for manual labor.

The combination of these features allows the nutrition bar production line to operate at high efficiency, minimizing human error and ensuring that each bar produced meets strict quality standards.

Fully automatic systems are designed to accommodate a variety of recipes and bar types, including energy bars, protein bars, and gluten-free options, making them highly versatile and scalable for different production needs.

Benefits of Fully Automatic Nutrition Bar Equipment

The rise of fully automatic nutrition bar equipment has brought a host of benefits to snack manufacturers. By incorporating automation into the production process, companies can address the challenges of efficiency, cost, and quality, all while meeting the rising consumer demand for healthier snack options. Below, we explore the primary advantages of using fully automatic systems, particularly in the context of nutrition bar production line, nutrition bar manufacturing machine, and nutrition bar equipment.

1. Enhanced Production Speed and Efficiency

One of the most significant benefits of fully automatic nutrition bar equipment is its ability to produce large quantities of nutrition bars at high speeds. Traditional manual methods or semi-automated systems often result in slower production rates and more inconsistent output. In contrast, nutrition bar production line can operate continuously, providing manufacturers with a significant boost in production efficiency. With precise control over each step of the process, automation eliminates bottlenecks and ensures that the production line runs smoothly without unnecessary downtime.

As John Smith, a leading expert in food manufacturing technology, once stated, “Automation in food production not only accelerates throughput but also optimizes the use of resources, making it a game-changer for companies seeking to scale up production while maintaining high-quality standards.”

2. Improved Consistency and Quality

Automated nutrition bar equipment ensures uniformity and consistency across every batch. The texture, shape, and size of the bars remain consistent throughout the production process. This level of precision is difficult to achieve with manual labor, where human error may cause variations in the final product.

Moreover, the controlled conditions of the production line—such as temperature, mixing time and cutting time—result in bars that have the same quality every time. This is crucial for maintaining brand reputation, as consumers expect consistent taste and texture from their favorite snack bars.

3. Reduced Labor Costs and Minimized Human Error

Fully automated systems significantly reduce the need for manual labor, thereby lowering labor costs. The tasks of mixing, shaping, cutting, cooling, and packaging, which would traditionally require a large workforce, can now be performed by a few operators overseeing the system. This reduction in labor requirements not only cuts costs but also minimizes the potential for human error, which can lead to inconsistencies or even product recalls.

The nutrition bar equipment is designed to operate with minimal human supervision, freeing up workers to focus on more critical tasks, such as quality control and maintenance, rather than repetitive and manual jobs.

The function of nutrition bar production line

Sugar boiled pot | can melt sugar, stir, and boil sugar together |

Mixer | mixing raw materials. With heat preservation effect, the inner wall is sprayed with Teflon, and the stirring shaft and stirring claws are sprayed with Teflon |

Cereals bar cutting machine | used for leveling, cooling, cutting and forming of products. |

Packaging machine | finally, the dried bar is packaged in a suitable container and labeled for distribution. Packaging is an important step to ensure that the product remains fresh and free from contamination during transportation and storage. |

Layout for the nutrition bar production line

Our machines can be flexibly arranged according to the size and dimensions of the factory. We can also customize the size of the machine according to the data you provide.

Sample of nutrition bar production line

Other substances and nutrients can be added as needed, such as chocolate, nuts, fruits, iron, calcium, vitamin D, etc.

How Fully Automatic Equipment is Revolutionizing the Snack Industry

The introduction of fully automatic nutrition bar equipment has had a profound impact on the snack industry, particularly as consumer preferences continue to evolve towards healthier, more convenient options. Automation in the production of nutrition bars has not only streamlined manufacturing processes but has also played a pivotal role in meeting the growing demand for nutritious snacks.

1. Meeting Increasing Consumer Demand for Healthier Snack Options

As more people shift towards health-conscious diets, the demand for nutrition bars—especially those that offer protein, fiber, and essential vitamins—has skyrocketed. In the past, snack manufacturers faced challenges in scaling up production to meet these needs while ensuring the bars' quality and nutritional value. However, fully automatic nutrition bar equipment has made it possible to produce high-quality, nutritious snacks at scale, without compromising on taste or texture.

By using a nutrition bar production line, manufacturers can efficiently produce large quantities of nutrition bars with the exact nutritional specifications required by health-conscious consumers. Whether it’s low-sugar, gluten-free, or high-protein bars, these automated systems can handle a variety of recipes and formulations, making them highly adaptable to market trends and consumer preferences.

2. Role of Automation in Scaling Production to Meet Market Needs

The rise of automation in nutrition bar production has also enabled manufacturers to scale up their operations to meet the ever-growing demand. With nutrition bar manufacturing machine systems designed to handle continuous production runs, snack companies can significantly increase output without sacrificing quality. Automation makes it easier to scale up production quickly in response to spikes in demand, whether driven by seasonal trends or changing consumer habits.

Automation also ensures that production lines remain efficient, even as output increases. By minimizing human involvement and reducing the chances of errors, fully automated systems help manufacturers maintain high standards of product consistency, even at larger volumes.

3. Contribution to Product Innovation and Customization in the Snack Industry

Fully automatic nutrition bar equipment has been key in fostering innovation in the snack industry. The ability to customize recipes and experiment with new ingredients is now more feasible due to the flexibility of nutrition bar equipment. Manufacturers can produce a wide variety of bars, each with unique nutritional profiles, ingredients, and textures, based on consumer demand for innovation.

This flexibility is particularly important as consumer preferences shift towards more specialized, niche snack options. For instance, the rise of vegan, paleo, and keto diets has prompted snack companies to introduce new types of bars with specific ingredient restrictions. The versatility of fully automatic equipment allows manufacturers to create small-batch runs of these specialized bars while maintaining efficient production schedules.

Moreover, the automation of processes from mixing to packaging provides manufacturers with the opportunity to streamline production and reduce time-to-market for new products, ensuring they stay competitive in a fast-moving industry.

If you are interested, I will recommend a company to you, please continue reading.

Recommended Company

Shandong Loyal Industrial Co.,Ltd. Is a Manufacturer Of Snacks Extruder Machine , Industrial Microwave Oven , Corn Flakes Production Line , And a Standing Director Of China Food And Drying Equipment Industry Association.

The Self-developed Twin-screw Extruder And Single-screw Equipment of Shandong Loyal Machinery Have Been Used In Production: Puffed Snack Food, Breakfast Cereal Corn Flakes, Fried Pasta, Bread Crumbs, Fruit Chips, Baby Food, Textured Soy Protein (tsp) Food, Fish Feed And Pet Food. a Variety of Snack Production Line Supporting Products.at The Same Time, The Batching, Drying, Flaking, Baking, Frying And Spraying Equipment Matching The Twin-screw Extrusion System Have All Achieved Independent Design And Production.

Our Extrusion System Is Widely Used In: Puffed Snack Foods, Breakfast Cereals, Vegetable Protein Meat Products, Soy Based Nutrition Bars, Reconstituted Rice, Grain Nutrition Powder, Modified Starch, Starch-based Sticky Music Children's Educational Toys, Degradable Starch-based Packaging Filling Materials, Bread Crumbs And Other Food Additives, Pet Food, Aquatic Feed, Biology And Chemical Industries.

Customer-specific Food Processing Plant Project Solutions

As one of the leading manufacturers of food processing equipment, we are always searching for new solutions that benefit our snack food customers. Our experienced frying engineers always find the optimal solution for your industrial batch and continuous frying system line application. That's why we also develop, design and produce custom fried snack production line.

Close collaboration with our customer is important to us even in the early development phase. No matter what the special requirements of instant noodles production line, snack food extruder machine, pasta production line application, we can develop a custom made food processing equipment to match your needs.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

Loyal Food Production Line meet the needs of customers to obtain snack food that meet the needs.

In ovens or drying units, electric or gas can be used as heating sources.

Loyal have a unique and efficient industrial continuous frying equipment for snack food extruder machine that provides the right crunch and desired moisture level.

The Industrial Microwave Sterilization Defrosting Drying Machine can be designed as a dry powder dosing system and a wet slurry dosing system as required.

Some snacks can also be fried according to taste requirements, and we also provide Fried Snack Production Line for the processing and packaging of fried extruded snacks.

Reference

The following are five authoritative foreign literature websites in the field of Industrial food machinery:

1. Food Engineering Magazine

Website: https://www.foodengineeringmag.com/

2.Food Processing Magazine

Website: https://www.foodprocessing.com/

3.Journal of Food Engineering

Website:https://www.journals.elsevier.com/journal-of-food-engineering

4. Food Manufacturing Magazine

Website:https://www.foodmanufacturing.com/

5. International Journal of Food Science & Technology

Website:https://onlinelibrary.wiley.com/