Do you know the feed production line?

Feed is certainly not unfamiliar to everyone. Dogs, cats, fish, rabbits and other animals need feed. Because the feed industry is developing rapidly, higher requirements are put forward for feed. In order to adapt to the development of the feed industry, Feed Production Line It came into being under this background. Do you know the feed production line? Let's introduce the production line in detail below.

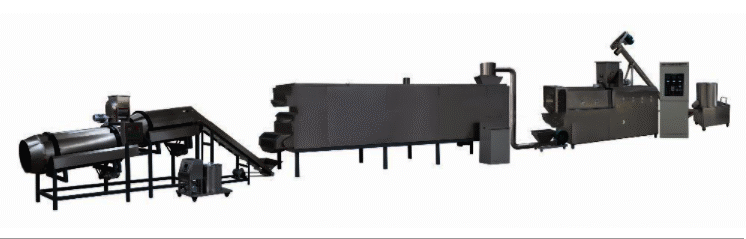

As shown in the figure below, what you see is the feed production line. It can be seen that the equipment is beautiful in appearance, the whole machine is made of stainless steel, and the machine parts are the most advanced. The equipment is reasonably designed, compact in structure, simple in operation, and low in investment. High efficiency, widely used in feed processing plants, breeding farms, etc. Its main features are as follows.

Features of feed production line:

1. Stable operation and advanced technology can meet the production needs of different customers in the current market.

2. The design is reasonable, the performance is superior, and the produced feed has good taste and rich nutrition, which can meet the needs of animals.

3. The raw material, temperature, moisture and other process parameters of the feed production equipment are adjustable, which is very convenient to use.

4. The manufacturing process of feed pellets, from the crushing of raw materials to the packaging of finished products, can be completed at one time with a high degree of automation.

5. The machine performance and product quality have reached the world's advanced level, with high efficiency, low consumption, and convenient operation and maintenance.

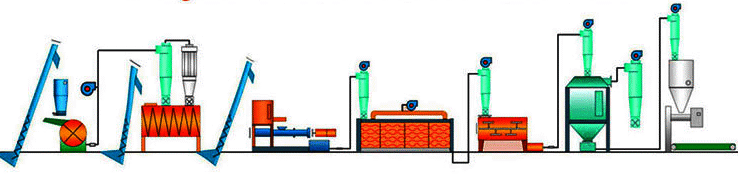

Process flow of feed production line:

Raw material → mixing → conveying → extrusion and puffing → conveying → drying → cooling → sieving → oil injection → seasoning → packaging

The specific process of the production line is as follows:

The pulverizer crushes the raw materials and mixes them evenly by the mixer, then enters the extruder, is processed by high temperature and high pressure, and then is transported to the dryer for drying. The temperature of the dried feed is very high and needs to be carried out. Cooling for the next step, the feed particles are of different sizes, so washing, sieving, and then seasoning, and finally packaging.

Equipment configuration of feed production line:

Mixer → conveyor → extruder → hoist → dryer → cooler → vibrating screen → elevator → fuel injection machine → automatic packaging machine

Working principle of feed production line:

The spindle and the flat mold drive the pressure roller to rotate under the action of friction. The temperature between the pressure roller and the mold plate will increase. Then the high temperature will mature the starch and denature and solidify the protein. Finally, the raw material is discharged from the mold hole, and the particles can pass through The throwing disc comes out of the machine, and the length of the particles can be controlled according to the angle of the cutter.

The composition and application of the production line:

The feed pellet machine is composed of a feeding system, an extrusion system, a drying system, a cooling system, a transmission system, and a control system. It has a wide range of applications. It can use corn meal, wheat flour, soybean meal, meat meal, etc. as raw materials to produce various animal feeds for dogs, cats, fish, birds, etc. It only needs to change the mold to produce feeds of different shapes.

Feed processing and production equipment is advanced equipment with reliable performance, convenient operation, low price, economical efficiency, and suitable for small and medium-scale production. Feed Production Line can produce poultry, livestock feed and fish feed. It is widely used in the production of feed pellets for various animals. Its appearance adapts to the development of the feed industry and brings great convenience to the feed industry.

The above is the relevant introduction of the feed production line, mainly talking about the characteristics of the production line, process flow, equipment configuration, working principle, composition and application content. I believe everyone has a certain understanding of this, and I hope it will be helpful to you.