Biscuit Production Line Efficient And Intelligent Baking Solutions

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/

In the modern baking industry, biscuit production has changed from traditional manual production to a highly automated and industrialized production process. The emergence of biscuit production lines has not only greatly improved production efficiency, but also ensured the stability and consistency of product quality. This article will introduce various aspects of the biscuit production line in detail, including its main components, production process, equipment advantages, and configuration solutions under different production requirements.

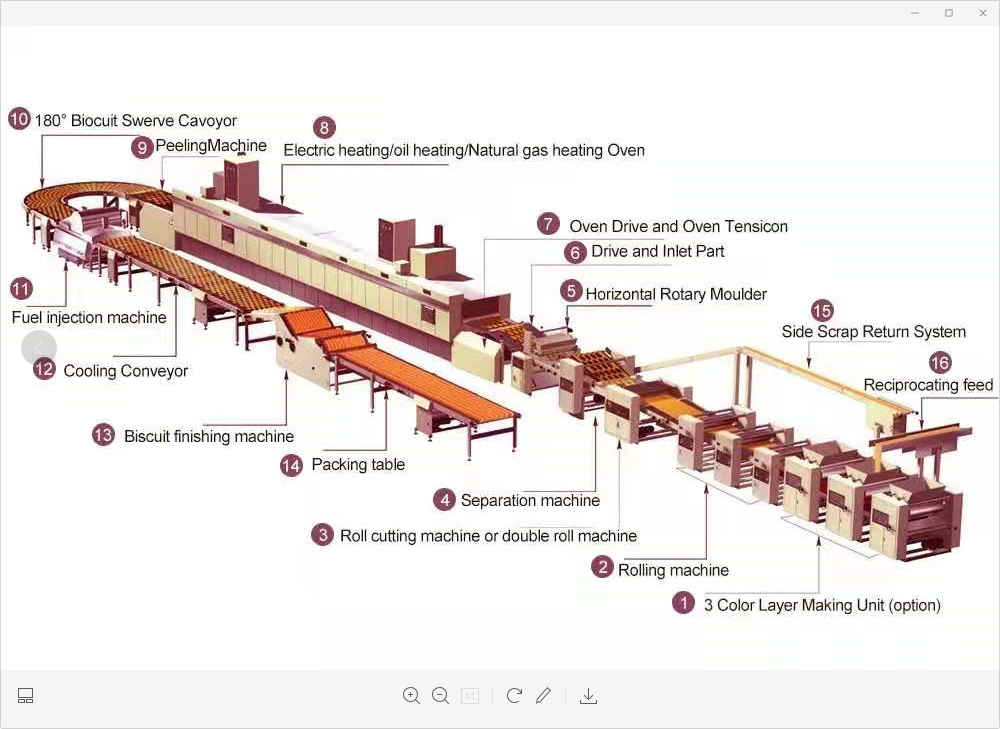

Overview of Biscuit Production Line

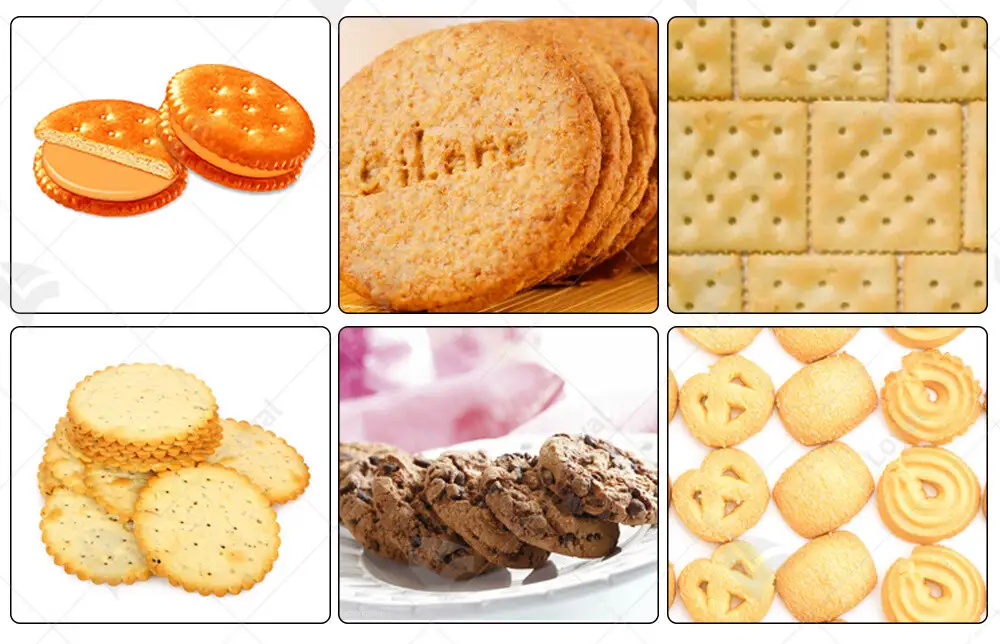

The biscuit production line is an automated equipment system specifically used for mass production of biscuits. It covers the entire production process from raw material mixing to finished product packaging, and is capable of producing a variety of biscuits, such as crisp biscuits, tough biscuits, and sandwich biscuits. Through highly automated equipment and precise process control, the biscuit production line can achieve efficient production to meet the needs of different customers.

The main components of the biscuit production line include raw material mixing equipment, molding equipment, baking equipment, cooling equipment, finishing equipment, and packaging equipment. These equipment form a complete production process through reasonable layout and connection. The output of the production line can be adjusted according to customer needs, from a small production line of 100 kg per hour to a large production line of 1,000 kg per hour, which can meet the production needs of enterprises of different sizes.

The main components of the biscuit production line

1. Raw material mixing equipment

Raw material mixing is the first step in biscuit production. Its purpose is to mix flour, sugar, butter, egg yolk powder and other raw materials in a certain proportion to form a dough suitable for subsequent processing. Raw material mixing equipment usually includes flour mixers and blenders.

Flour mixer

Function: The main function of the flour mixer is to mix flour and other raw materials evenly. It can be used alone or in conjunction with other equipment.

Features:

The body is made of all stainless steel, not easy to rust and easy to clean.

The mixing teeth are thickened, not easy to deform, and easy to clean.

Adopting one-piece molding design, no weld joints, no material storage, easy to clean.

Suitable for mixing crisp and tough raw materials.

With a safety control system to effectively protect the operator.

The motor adopts high-quality national standard motor, energy-saving and efficient.

Mixer

Function: The mixer is used to further mix the dough to make it suitable for shaping.

Features:

Adopts Z-shaped mixing teeth, suitable for mixing tough and crisp biscuits.

With a protective cover to ensure safe operation.

The motor adopts high-quality national standard motor, which is energy-saving and efficient.

Forming equipment

Forming equipment is a key link in the biscuit production line. It processes the mixed dough into biscuits of various shapes. Forming equipment mainly includes tough biscuit forming machines and crisp biscuit forming machines.

Tough/Hardbiscuitequipment

Function: Process the dough into the shape of tough biscuits.

Features:

Suitable for large-scale production of 150-200 kg/hour and above.

Food-grade PU conveyor belt to ensure food hygiene.

The pressing roller adopts an exclusive design. From the feed to the discharge end, the diameter of the pressing roller is from large to small. The thickness of the pressed dough is uniform and not easy to break.

Provide 200,000 mold designs to meet the needs of different customers.

Equipped with a waste material recovery device, the belt is made of PC material and has an anti-deflection guide roller.

Softbiscuit making machine

Function: Process the dough into the shape of crisp biscuits.

Features:

Suitable for large-scale production of 150-200 kg/hour and above.

Food-grade PU conveyor belt to ensure food hygiene.

The pressure roller is made of alloy material with extremely high hardness to ensure the quality of forming.

The mold material can be brass or PE to meet different needs.

The bottom is equipped with wheels to facilitate the replacement of soft and hard biscuit machines.

There are baffle plates on both sides of the mold to prevent leakage.

There is a material receiving plate at the bottom, so the remaining materials can be recycled and reused, which is easy to clean.

Baking equipment

Baking is one of the most important links in the biscuit production process, which determines the taste and quality of the biscuits. Baking equipment mainly includes tunnel ovens and oven control systems.

Tunnel oven

Function: Bake the formed biscuits to achieve the desired taste and color.

Features:

There are various heating methods, including electricity, gas and diesel.

The insulation cotton is made of aluminum silicate, which has good thermal insulation performance.

The frame material is made of carbon steel square tube, which is strong and durable.

The mesh belt adopts a herringbone design, which is corrosion-resistant,high-temperature resistant and has a long service life.

Automatic pneumatic deviation correction device ensures the smooth operation of the mesh belt.

Multi-zone intelligent temperature control system, the temperature of each temperature zone can be set and the temperature is uniform.

High-quality insulation materials are used, with high thermal efficiency, energy saving and high efficiency.

Fully automatic PLC temperature control system, flexible operation and high safety performance.

Oven control system

Function: Control the temperature and operation status of the oven.

Features:

Zoned temperature control, baking on both sides to ensure that the cookies are heated evenly.

Adopt M-type electric heating tube, heat is evenly dispersed.

The gas oven has a built-in ceramic infrared combustion tube with high combustion efficiency.

The oven wall is filled with high-quality perlite, which has good thermal insulation and low shell temperature to protect the safety of workers.

Cooling equipment

The function of the cooling equipment is to cool the baked biscuits to room temperature for subsequent packaging. The cooling equipment mainly includes cooling conveyors and cooling lines.

Cooling conveyor

Function: transport biscuits from the oven to the cooling area.

Features:

Food-grade mesh belt to ensure food hygiene.

Using PU material, in line with FDA food-grade certification, good oil resistance, strong anti-corrosion ability.

The belt edge is neat and not easy to deviate.

The PU production line can be as thin as 0.6mm, with more precise thickness, beautiful surface and anti-static properties.

Cooling line

Function: Cool the biscuits to room temperature.

Features:

The length can be adjusted according to the production demand, generally 18 meters.

Adopt food-grade mesh belt to ensure food hygiene.

Adopt PU material, meet FDA food-grade certification, good oil resistance, strong anti-corrosion ability.

Sorting equipment

The function of the sorting equipment is to sort and screen the cooled biscuits to ensure product quality. The sorting equipment mainly includes biscuit sorting machines and sorting tables.

Biscuit sorting machine

Function: sort the cooled biscuits and remove unqualified products.

Features:

Suitable for large-scale production of 150-200 kg/hour and above.

Workers can pick out unqualified biscuits here and manually sort and arrange qualified biscuits.

Arrangement table

Function: Provide workers with a working platform for arranging biscuits.

Features:

Made of stainless steel, easy to clean.

The surface is flat and easy to operate.

Packaging equipment

The packaging equipment is the last link of the biscuit production line. It will pack the sorted biscuits to ensure the quality of the products during transportation and sales. Packaging equipment mainly includes trayless packaging machine, sandwich packaging machine and pillow packaging machine.

Trayless packaging machine

Function: Pack biscuits without trays.

Features:

Suitable for the production of small-package biscuits.

Fast packaging speed and high efficiency.

Sandwich packaging machine

Function: Packing sandwich biscuits.

Features:

Suitable for the production of sandwich biscuits.

Fast packaging speed and high efficiency.

Ensure that the sandwich biscuits are not squeezed.

Pillow packaging machine

Function: pillow packaging of biscuits.

Features:

Suitable for packaging of various types of biscuits.

Fast packaging speed and high efficiency.

Beautiful packaging effect, suitable for sales.

Equipment advantages of biscuit production line

The equipment of biscuit production line has many advantages and can meet the needs of different customers. The following are the main equipment advantages of biscuit production line:

Efficient production

High degree of automation: The biscuit production line adopts highly automated equipment. From raw material mixing to finished product packaging, the whole process does not require human intervention, which greatly improves production efficiency.

Adjustable output: The output of the production line can be adjusted according to customer needs, from a small production line of 100 kg per hour to a large production line of 1,000 kg per hour, which can meet the production needs of enterprises of different sizes.

Stable product quality

Precise control: The production line uses a multi-zone intelligent temperature control system and a fully automatic PLC temperature control system, which can accurately control the baking temperature and time to ensure the stable quality of the biscuits.

Hygiene and safety: The equipment is made of food-grade materials and complies with FDA food-grade certification to ensure food hygiene and safety.

Energy saving and high efficiency

Energy-saving design: The production line uses high-quality insulation materials and energy-saving motors, which can effectively reduce energy consumption.

Residual material recovery: The molding equipment and injection equipment are equipped with residual material recovery devices, which can recover the remaining raw materials and reduce waste.

Easy operation

User-friendly: The operation interface of the production line is displayed in full Chinese, which is easy to operate and easy to use.

Safety protection: The equipment is equipped with a safety control system, which can effectively protect the safety of the operator.

Summary

The biscuit production line is an efficient and intelligent baking solution that can meet the production needs of different customers. Through highly automated equipment and precise process control, the biscuit production line can achieve efficient production and ensure the stability and consistency of product quality. Whether the customer needs small or large production, the biscuit production line can provide a suitable configuration. Choosing a biscuit process line means choosing an efficient, stable and energy-saving production method.

Shandong Loyal Industrial Co., Ltd biscuit process line is centered on "precision craftsmanship + innovative technology" and has built a full-chain solution from raw materials to finished products. Whether it is the structural wisdom of the wavy noodles, the flexible adaptation of multiple production capacities, or the forward-looking layout of health and intelligence, they all demonstrate the high professionalism and market insight of the modern food industry. For food companies, choosing the Shandong Loyal Industrial Co., Ltd production line is not only about obtaining a production equipment, but also about obtaining the key to the global fast food market - from classic flavors to innovative forms, from regional brands to international giants, it has always helped customers to continue to lead the competition with stable performance and excellent quality.

At present, Shandong Loyal drying equipment is also known by more and more people. A variety of models, different sizes, widely used in the drying of Chinese herbal medicines, plant seeds and various dehydrated vegetables. Shandong Loyal Industrial Co., Ltd has won the trust and cooperation of its continuously enhanced innovation ability, outstanding flexible customization ability, and increasingly perfect delivery ability, and is favored by customers at home and abroad.

Partnering with Shandong Loyal Industrial Co,.Ltd means joining a global community of industry leaders. We understand that your success hinges on speed, reliability, and consumer trust—and our production lines are built to exceed these expectations. Choose innovation. Choose sustainability. Choose Shandong Loyal Industrial Co,. Ltd as your strategic ally in shaping the future of nutrition. Let’s transform your vision into a reality that nourishes both bodies and bottom lines."

The products are perfect, and the mesh belt dryer, energy room drying, drying and sterilization equipment, single and twin-screw puffed food machinery machinery and equipment equipment are becoming more and more popular now. Myanmar, Thailand,India, Pakistan, Kazakhstan, Uzbekistan, Turkmenistan , Jordan , Yemen, Iraq, Egypt , Algeria, Morocco , come Shandong Loyal Machinery has won wide acclaim at home and abroad. In the future, we will continue to provide higher quality equipment and better services.