Advanced Fully Automatic Instant Noodle Production Line: Achieving High Efficiency and Energy Conservation

Introduction

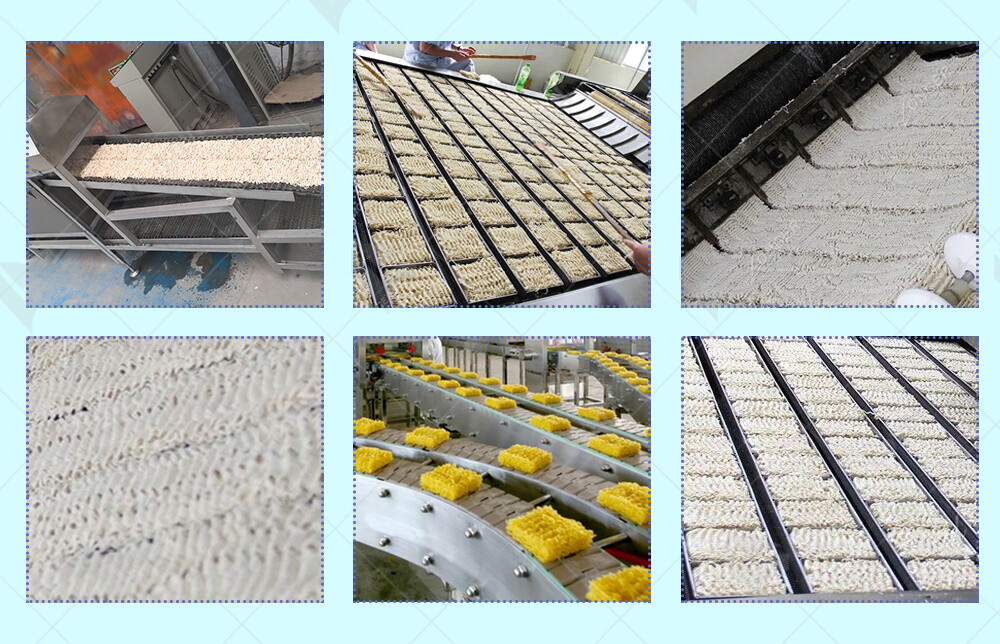

In terms of appearance, the noodle cake of instant noodles is golden yellow, with regular and fine textures, which is the result of precise rolling and skillful cutting. Its shapes are diverse. The common round noodle cake is like a golden full moon, while the square noodle cake is neat and orderly. Some noodle cakes even have specially designed wavy edges, adding a unique aesthetic appeal. Looking at those seasoning packets, the powdered seasoning packet is carefully blended with salt, sugar, spices, flavor enhancers, etc., rich in color and strong in aroma; the sauce packet is made by boiling refined vegetable oil, meat, vegetables, etc., thick in texture and fragrant; in the dehydrated vegetable packet, carrot dices, chopped green onions, spinach leaves, corn kernels and other vegetables are skillfully dehydrated, retaining their original color and nutrition.

Overview of Instant Noodle Industry

The instant noodle production line has seen tremendous growth in recent decades, driven by the increasing global demand for quick, affordable, and easy-to-prepare meals. Instant noodles are now a staple in many households across the world, especially in Asia, but also in other regions, where they provide a convenient food option for busy lifestyles. As a result, manufacturers are under constant pressure to improve the efficiency, consistency, and cost-effectiveness of their production processes.

The market for instant noodles is projected to continue expanding, as consumer demand increases in both developing and developed countries. This growth has prompted a shift toward more advanced and automated manufacturing techniques. Moderninstant production lines are designed not only to meet increasing demand but also to address the rising need for sustainability and energy conservation in production.

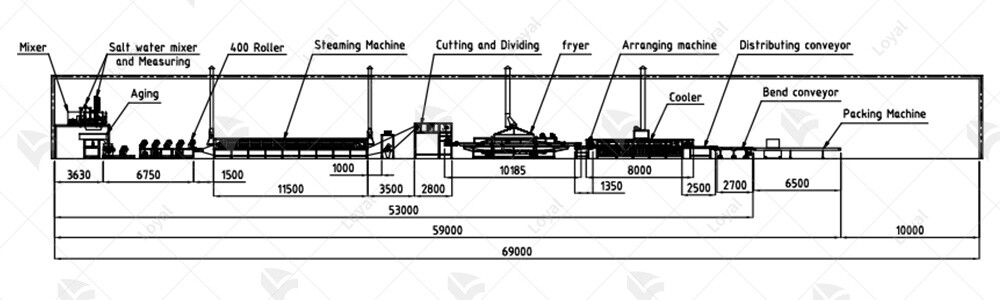

Equipment list of Instant NoodlesProduction Line

For small production instant noodle production lines (less than 11,000pcs/8h)

Mixer →Compound rolling and shaping machine →Hoister →Steaming machine →Cutting machine →Fryer →Cooling conveyor →Packing machine

For large production instant noodle production lines (morethan 30,000pcs/8h)

Alkaline water mixing tank→Alkali water measuring device→Dough mixer →Round disk aging machine→Compound rolling and shaping machine→3 Layer steaming machine→Cutting machine→Fryer→Arranging machine→Air cooling machine→Conveyor→Packging machine.

Working Process of the Instant noodles Production Line

1. Alkaline water mixing tank: used to mix alkali and water in a certain proportion to make alkaline water that meets production requirements. Adding it to flour can enhance the toughness and elasticity of noodles and improve the color and taste of noodles.

2. Alkali water measuring device: accurately measure and add salt water to flour. Salt water can adjust the gluten formation of flour, enhance the toughness and ductility of dough, and at the same time play a certain role in preserving and improving flavor.

3. Dough mixer: fully mix and stir flour, water, salt, alkali and other raw materials to form dough with certain elasticity, toughness and humidity, providing a basis for subsequent processing.

4. Round disk aging machine:let the kneaded dough stand in the disc-shaped equipment for a period of time, so that the moisture distribution in the dough is more even, the gluten network is further formed and stabilized, and the process performance and product quality of the dough are improved.

5. Compound rolling and shaping machine:the matured dough is gradually rolled into a dough sheet with uniform thickness through multiple sets of rollers, and then the dough sheet is cut into noodles through the forming device to determine the shape and specifications of the noodles.

6. Steaming machine: Generates steam to provide heat source for steaming noodles. It allows noodles to mature in a short time, prepares for the subsequent frying or drying process, and improves the taste and rehydration of noodles.

7. Cutting machine: Cuts the continuous noodles according to the set length to form a dough blank that meets the packaging specifications.

8. Fryer: Put the cut dough blank into hot oil for frying, so that the dough is quickly dehydrated and dried, fixes the shape of the noodles, and gives the dough a unique aroma and taste, extending the shelf life.

9. Oil tank: Stores edible oil used in the frying process and provides a stable oil source for the fryer. At the same time, the oil is filtered, heated and circulated to ensure the quality of the oil and the frying effect.

10. Sorting machine: Finishes the dough to make it more neat in appearance, removes debris and excess grease on the surface of the dough, and prepares for subsequent packaging.

11. Cooling machine: Through air cooling or water cooling, the temperature of the cake after frying is quickly reduced to solidify the oil inside the cake, which is convenient for packaging and prevents the cake from deteriorating or deforming due to high temperature.

12. Conveyor: Transport materials such as dough, noodles, noodles, cakes, etc. between various equipment on the production line to ensure the continuity and automation of the production process and improve production efficiency.

13. Packaging machine: The cooled cakes and seasoning packets are packaged in a certain way to form the final instant noodle product, which plays a role in protecting the product and facilitating storage and sales.

Parameters of Each Machine in the Instant Noodles Manufacturing Line(Taking small production as an example)

MACHINE NAME | TECHNICAL PARAMETER |

ALKALI WATER MIXING TANK | Rotating paddle speed:260r.p.m Power:4Kw Maximum capacity:15-20kg/one time Size:800x500x600m Functional:Mixing the raw material uniform. |

ROLLING AND PRESSING MACHINE

| Rolling and pressing machine Roller Length:2400mm Capacity:150kg/h Power:3kw Noodles Diameter:1-3mm(square or round) Dimension(L×W×H):2200×800×1600mm Consist 6 sets of press rollers, Frequency Roller Material:45 # steel, after heat treatment, increases the hardness of the roll, the noodles that are pressed out are lighter and stronger Cover Material:Stainless steel |

CONVEYOR

| Lifting base: 50-100mm Transmission: Passive High and low points: 0.85m high and 0.35m low Size: 1.9 × 0.4 × 1.1m To Deliver the Shaped Noodles to Next Device- Boiling machine |

STEAM BOILING MACHINE

| Boiling part:2 sets,5 m length/set,totally 10m length Material: Stainless steel Body thickness: 2mm Effective convey length:5m Convey speed:infinite variable speed Boiling time:70~90 seconds Boiling temperature:96~98℃ Capacity:180kg/h Heating Power:90Kw Driving power:0.75kw Totally powder:90kw+0.75kw Dimension(L×W×H):10000×650×1100mm Using the electrical to heating the water to have steam, then Boiling the noodles by steam. |

CUTTING MACHINE | Lifting base: 50-100mm Cutting Power Power:0.55kw Size:1900×400×1500mm It is used to cut noodles and adjust the frequency by controlling the size of noodles. |

SORTING MACHINE

| Dimension:600*600*800mm Function: Put the cutter noodles here. The workers need put the noodles from this plate to the noodles box of next device-Drying machine. |

AUTOMATIC ELECTRIC FRYER

| Shape of per noodles:round,square(accroding to customer request) Production Capacity: 11000pcs-13000pcs /8 hours Per piece weight:=> 120g/piece Speed:adjustable Temperature:150℃~170℃ Frying time:60~90 seconds Installation Power:90Kw Consumption Power :65KW Oil consumption ratio:20~22% Dimension(L×W×H):5100×1100×2000mm |

COOLING MACHINE

| Effective length:5m Convey speed:adjustable Cooling power:5×120W, 5 PCS fans Dimension(L×W×H):5000×600×1200mm |

PILLOW PACKING MACHINE FOR BAG PACKING

| Model:LY-320 Film Width:Max.320mm Bag Making Length:65-190mm Bag Making Width:30-110mm Packing Speed: 40-230bags/min Film Roll Diameter:Max.320mm Power:2.6kw/220v,50/60hz Outside Dimension:4000*720.1500mm Gross Weight:5000kg |

Advantages of Instant NoodlesProduction Line

1.High production efficiency

The fully automatic production line can realize the continuous automatic operation of a series of processes from raw material transportation, mixing, calendering, cutting, steaming, frying to packaging, which greatly reduces the manual operation links, has fast production speed and high output, and can meet the needs of large-scale production.

2.Stable product quality

The production line adopts advanced automatic control systems and precise metering devices, which can strictly control the parameters of each production link, such as the moisture content of the dough, the thickness of the calendering, the temperature and time of frying, etc., so as to ensure the stability and consistency of product quality and reduce the defective rate.

3.Save labor costs

Due to the high degree of automation, a large number of manual operation positions are reduced. A fully automatic instant noodle production line only requires a few operators to monitor and maintain, which can save a lot of labor costs compared with traditional manual production lines.

4.High hygiene standards

The fully automatic production line usually adopts a closed production process, which reduces the contact between the product and the external environment and reduces the risk of contamination. At the same time, the equipment is easy to clean and disinfect, meets the hygiene standards of food production, and can effectively ensure the hygiene and safety of the product.

5.Strong process flexibility

By adjusting the parameters and configuration of the production line, instant noodles of different specifications, flavors and varieties can be produced, such as different noodle weights and shapes, different seasoning package combinations, etc., to meet the diverse needs of the market, with strong process flexibility and product adaptability.

Features of Automatic Instant Noodle Plant

1.Highly automated production process | Precise delivery and mixing of raw materials Ripening and rolling in one go Intelligent molding, steaming and drying Efficient and automated packaging |

2.Streamlined and efficient production chain | Seamless material transmission Integrated packaging process |

3.Accurate and consistent product quality | Accurate raw material ratio Real-time monitoring and precise control |

4.Automation system guarantees product quality | Stable operation to avoid fluctuations Intelligent detection to eliminate defective products Environmental monitoring and adjustment |

5.Greatly reduce waste | Avoid human errors Precise control to reduce losses |

Our after-sales services

We provide comprehensive after-sales services. The equipment warranty period is 1 years. During the warranty period, if the fault is not caused by human factors, we will repair or replace parts free of charge; arrange professional technicians to come to guide installation and commissioning to ensure the normal operation of the equipment; provide a 7×24-hour after-sales hotline to answer your questions encountered during use at any time; make regular return visits to understand the use of the equipment and provide technical support in a timely manner.

Why Choose Us

We are able to provide customers with solutions to meet a variety of needs, customizing equipment to produce a variety of food categories. Whether it is a product based on rice, wheat flour or starch, our equipment can meet diverse production needs. This versatility allows our customers to flexibly respond to changing market demands and gain a competitive advantage.

We are proud to serve global customers, who are not only in China, but also in Canada, the United States, South Korea, Nigeria, Zimbabwe, Afghanistan, Algeria, Ghana, India, France, the Philippines, Malaysia and Sri Lanka. Our customers include many large food companies that are leading the global food industry. The long-term partnerships we have established with our customers enable us to provide highly customized food machinery solutions.

We are professional manufactory of food machinery, snacks food machinery.

22 experienced engineers is working for us whose job is to research new machines, design for clients, commission equipments for clients.

24 Hours' service and 15 after sales service personnels help our clients to solve all the errors of our machines as soon as possible.

We mainly deal with the manufacture, research and development of the snacks food machinery. According to clients' different requirements, we could offer the whole complete processing line for all kinds of expanded snacks, 2D and 3D pellet, potato chips, corn flakes, nutrition powder, pet food and so on. And our technical assistance will help clients produce high quality products all the time.

If you want to know more story about LOYAL brand, here can help you - https://www.facebook.com/Foodextruderfactory/