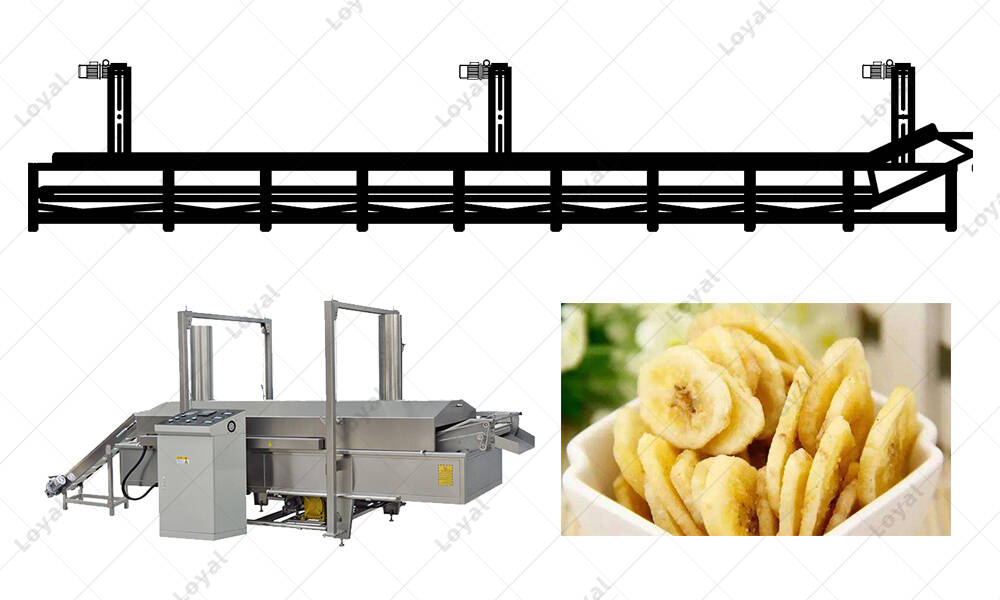

Hot sales Industry Banana Chips Frying Machine Continuous Fryer Machine

Loyal hot sales industry banana chips frying machine continuous fryer frying machine is fully automatic and can process and produce all types of banana chips. Banana chips frying machine continuous fryer has high production efficiency and a wide range of applications, and has become a trusted frying equipment for banana chips frying machine manufacturers.

Shandong Loyal has established a complete service system for fryer continuous banana chips frying machine, providing high-quality and low-cost frying equipment, and at the same time providing complete after-sales service of banana chips frying machine, so that you could choose Loyal hot sales industry banana chips frying machine.

Hot sales Industry Banana Chips Frying Machine Continuous Fryer Machine Specifications :

| Price | Check with Frying Machine Team Saler |

| Place of Origin | China |

| Min.Order Quantity | 1set |

| Payment Terms | T/T,L/C,D/P |

| Delivery Detail | 20days--35days |

| Team | Professional Fryer technology team |

| Honor | A Number Of National Fryer Equipment Patents |

| Technology | 8 Years Of Fryer Technology |

Hot sales Industry Banana Chips Frying Machine Continuous Fryer Machine Detail Introduction :

The hot sales industry banana chips frying machine continuous fryer machine is manufactured to make crispy fried chips from natural bananas, banana potatoes, etc. The production process of this commercial banana chip line mainly includes washing, peeling, slicing, blanching, dehydrating, frying, deoiling, seasoning, and packaging. And according to different customer needs, the banana chips making machine can be customized into a semi-automatic banana chip production line and a fully automatic banana chip production line, the output is between 50kg/h and 1000kg/h.

What is Banana Chips Frying Machine?

1.The industry banana chips frying machine consists of the frying system, automatic elevating system, automatic de-oil system, automatic conveying and cooling system and can finish fry,mix, de-oil and convey automatically. Hot sales industry banana chips frying machine continuous fryer machine can use electricity,gas or diesel as heating source.

2. Compact structure of fryer, elevate, de-oil, convey, cooling function.

3. Adopt PLC control achieves totally automatic working,imported gas, diesel burner guarantee best power.

4. Consumption with higher efficiency.

5. Manuals and automatic control way, operation flexible.

Technical Parameters And Price Of Banana Chips Frying Machine

Technical Parameters And Price Of Banana Chips Continuous Fryer Machine | |

| Product Name | Continuous Frying Machine |

| Machine Material | Food Grade Stainless Steel 304 |

| Temperature | 0 ~ 250° |

| Belt Width | 400/600/800mm/Customized |

| Load Capacity | 100/300/500KG/Customized |

| Heating Methods | Electric/Gas/Diesel |

| Available Voltage | 110/120/220/240/380/420 |

| Price Cost | 4,500USD---20,000USD |

The Production Flow Chart Of Continuous Fryer Banana Chips Frying Machine

Automatic hot sales industry banana chips frying machine continuous fryer machine is made of food grade stainless steel, consists of lifting system, conveying system, gas heating system, blowdown system, oil circulation system, smoke exhaust system and electric control system.

How Are Commercial Banana Chips Made?

Main Equipment Of Industry Banana Chips Frying Machine Continuous Fryer Machine | |

1 | Banana chips cutting machine: Hot sales industry banana chips frying machine continuous fryer machine use cut banana into slice.thickness can be adjusted |

2 | Hoist machine :Transfer the sliced banana to the fryer machine |

3 | Frying machine: Banana chips frying making machine fries the banana chips with the exact temperature of oil, and makes potato chips high quality and taste.this machine is the most advanced one, which adopts oil and water mixing. The oil in the above layer to fry banana chips, and the residue will be precipitated in the following water. So it extends the using time of oil. After working, the water will be run away along with the residue. |

4 | Vibration oil remover: Use the principle of vibration to remove oil from banana chips. |

5 | Air cooler:Reduce the temperature of the fried banana chips. |

6 | Flavoring machine: And use the spray to add the seasoning, not easy to break, but it can make the banana chips delicious. |

The Application Of Continuous Fryer Banana Chips Frying Machine

1. Cooked wheaten food: fried dough twist, rice crust, honey food, Honey Mito, deep-fried dough sticks, Fried Glutinous Rice Balls with Sesame, gluten, polished glutinous rice stick, caramel treats, thin fried dough twist, etc.

2. Meat: braised chicken (coloring), pressed salted duck (coloring), braised pork, ball, sliced dried beef, streaky pork, drumstick, pig's feet, etc.

3. Nut fruits: groundnut kernels, green soya bean, broad bean, sunflower seed.

4. Bean products: dried tofu, bean curd, fish bean curd, bread made by tofu.

5. Marine food products: various fish, peeled prawns, scallop, mytilidae, aberdeen fish, squid rings, squid.6. Miscellaneous: vegetable pie, tempura, eggplant box, lotus root box, various fried puffed food with syrup and paste.

What Is Advantage Of Banana Chips Frying Machine?

The Advantage Of Banana Chips Frying Machine | |

1 | Hot sales industry banana chips frying machine continuous fryer machine not only keep the frying oil clean, improve product quality, prolong shelf life, but also bring higher dosage value to the product. |

2 | The advanced mechanical configuration and control always maintains a good working condition, which not only increases the output, but also makes the product quality stable, and the color, aroma and taste are unified. |

3 | The machine automatically filters, without frequent oil changes, which can greatly extend the service life of frying oil. The oil consumed by the product during frying is equivalent to the oil absorbed by the product, saving fuel. |

Which Market Did The Loyal Industrial Banana Chips Frying Machine?

Customer Have Formula Request Of Continuous Fryer Banana Chips Frying Machine | |

1 | 300KG/H Guinea Continuous Continuous Fryer Banana Chips Frying Machine |

2 | 500KG/H PLC Control Continuous Fryer Banana Chips Frying Machine For Sale In Puerto Rico |

3 | 600KG/H Industrial C Continuous Fryer Banana Chips Frying Machine For Sale In Bolivia |

4 | 300KG/H Dough Snack Fryers For Sale In Argentina |

5 | 100KG/H Fully Automatic Industrial Continuous Dough Snack Fryers For Sale In Benin |

6 | 200KG/H PLC Control Fully Automatic Industrial Continuous Dough Snack Fryers For Sale In British Indian Ocean Territory |

7 | 300KG/H Hot Sales Industry Banana Chips Frying Machine Continuous Fryer Machine For Sale In Chile Factory |

Cooperated Customer For Laboratory Machine Of PLC Control Continuous Fryer Banana Chips Machine | |

1 | Senegal 800KG/H Industrial Continuous Dough Snack Fryers |

2 | 300KG/H Industrial Continuous Dough Snack Fryer For Sale In Côte d'Ivoire |

3 | 400KG/H Industrial Continuous Dough Snack Fryer For Sale In Sold In Russia |

4 | 600KG/H Industrial Continuous Dough Snack Frying Machine For Sale In Sold In Denmark |

5 | 200KG/H Plc Control Continuous Dough Snack Fryer For Sale In Dominica |

6 | 700KG/H Industrial Dough Snack Fryer For Sale In Egypt |

7 | 300KG/H Industrial Continuous Dough Snack Fryer For Sale In Sold In Ethiopia |

Cooperated Customer Request Engineer Installation Of Banana Chips Fryer In 2021 | |

1 | 300KG/H PLC Control Continuous Dough Snack Fryer For Sale In Uzbekistan |

2 | 100KG/H Industrial Fully Automatic Pasta Processing Line For Sale In Senegal |

3 | Mozambique 300KG/H Fully Automatic Pasta Processing Plant |

4 | 500KG/H Thai PLC Control Continuous Dough Snack Fryers Factory |

5 | Uzbekistan 600KG/H PLC Control Continuous Dough Snack Fryer Factory |

6 | 500kg/H Fully Automatic Frying Fish Processing Line For Sale In Germany |

7 | 200KG/H Fully Automatic Potato Chip Production Line For Sale In Guinea Factory |