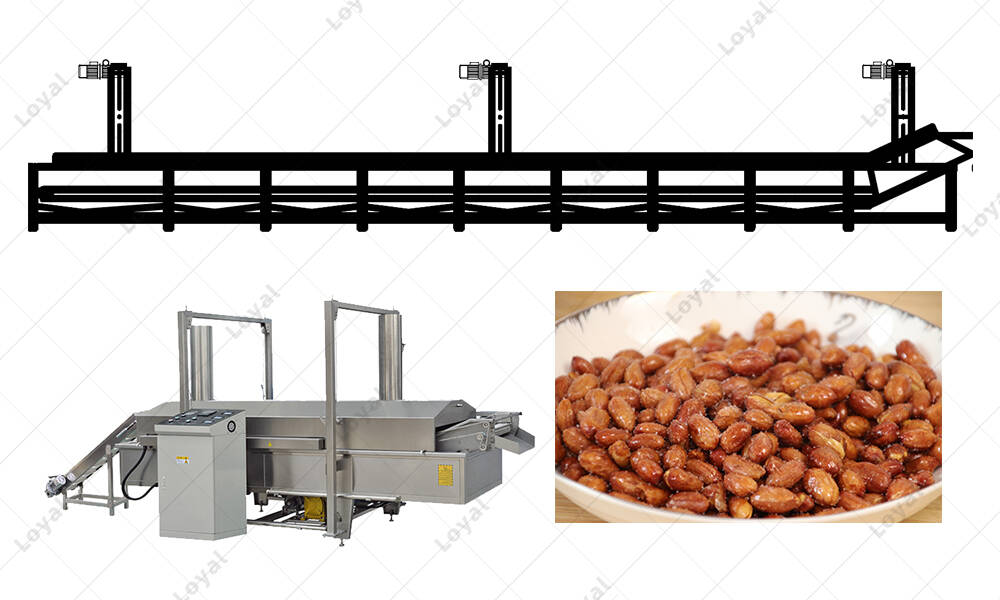

Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line

As a professional continuous peanuts frying machine manufacturer, our loyal commercial deep fryer for peanut snack automatic peanut fryer machine processing line have been popular all over the streets and all types of supermarkets. The reason is that the use of peanut continuous fryer frying mechanized equipment not only increases production capacity, but also can save energy, reduce energy consumption, and greatly reduce production costs. The trend of food machinery energy saving and environmental protection. The use of peanut continuous fryer has become the development trend of the future food factory.

Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line Specifications :

| Model Number | Commercial Automatic Peanut Fryer Processing Line |

| Place of Origin | China |

| Min.Order Quantity | 1set of Automatic Peanut Fryer Machine Processing Line |

| Payment Terms | D/P,T/T, |

| Delivery Detail | 20days--35days |

| Team | Fryer Machine Technical Team |

| Sale Team | Automatic Peanut Fryer Machine Processing Line |

| Technology | 8 Years Of Fryer Technology |

Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line Detail Introduction :

The commercial deep fryer for peanut snack automatic peanut fryer machine processing line has zone temperature control, and scientific use of the specific gravity relationship between vegetable oil and animal oil, so that the working oil in the middle and upper layers is always kept pure, and the fried food not only the color, aroma and taste are all good, the appearance is clean and beautiful, and the product quality is improved and the shelf life is prolonged.

The technology of commercial deep fryer for peanut snack automatic peanut fryer machine processing line makes food residues, excess water and heavy metals produced during the frying process quickly leave the high temperature area and sink into the low temperature area, and are drained with water. When the frying oil is too dry, the water layer can be supplied again. Frying the oil layer with proper moisture, frying machine equipment and food frying machinery can prevent the fried food from coking and carbonization, and commercial deep fryer for peanut snack automatic peanut fryer machine processing line can effectively control the production of carcinogens and ensure the health of customers.

What’s The Frying Time For Continuous Commercial Deep Fryer For Peanut Snack

Continuous commercial deep fryer for peanut snack automatic peanut fryer machine processing line adopts oil-water mixed frying technology, and uses the principle of specific gravity of oil and water to heat the oil layer. During the frying process, all the residues are immersed in low temperature water, which fundamentally solves the problem of carcinogens caused by burning residues in traditional frying machines and oxidation and blackening of high-temperature oil.

Parameters Of Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line

| The Parameters Of Continuous Automatic Peanut Fryer Machine Processing Line | |||||

| Model | Size | Oil quantity | Heating power | Effective network width | Working oil temperature |

| Ly2000/400 | 3600*980*2200 | 320L | 38kw | 360 | 140-200℃ |

| Ly3000/400 | 4600*980*2200 | 450L | 56kw | 360 | 140-200℃ |

| Ly3500/450 | 5200*1026*2300 | 620L | 78kw | 410 | 140-200℃ |

| Ly4000/500 | 5700*1080*2300 | 780L | 120kw | 460 | 140-200℃ |

| Ly4500/600 | 6200*1180*2350 | 960L | 176kw | 560 | 140-200℃ |

| Ly6000/600 | 7800*1180*2350 | 1220L | 210kw | 560 | 140-200℃ |

What Is The Best Oil For Commercial Deep Fryer Peanuts Snack?

1.Oils that consist mostly of saturated and monounsaturated fats are best for commercial deep fryer for peanut snack automatic peanut fryer machine processing line because they’re the most stable at high heat.

Healthy oil for cooking will:

A.Have a high smoke point.

B.Be stable, so they don’t react with oxygen when heated.

C.Taste is also important. When deep frying, oils with a neutral flavor are usually preferable.

2.What kind of vegetable oils can be used in the deep frying work? Palm oil consists mostly of saturated and monounsaturated fats, making it a great choice for deep frying. The flavor can be neutral, particularly if you use the unrefined variety known as red palm oil.

Principle Of Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line

The continuous commercial deep fryer for peanut snack automatic peanut fryer machine processing line is designed according to the principle of different specific gravity of oil and water, insoluble in water and automatic stratification. The continuous deep fryer is mainly suitable for larger food production enterprises. Automatic peanut fryer machine is characterized by continuous production, energy saving, labor saving, and more uniform product quality. In terms of energy, electricity, heat transfer oil, coal, natural gas, liquefied gas and external circulation heating can be selected. There is a high temperature oil layer, a buffer layer and a water layer in the oil tank. The slag thrown by the fried material falls into the water layer through the buffer layer, and the high-temperature oil layer does not carbonize and is regularly discharged from the slag discharge port. The residue floating on the surface of the hot oil is driven by the hot oil circulating pump to enter the filter tank to be filtered out.

Customer Cases For Commercial Deep Fryer For Peanut Snack Automatic Peanut Fryer Machine Processing Line For Factory In 2021

The company has committed to the research and development of food machinery; the commercial deep fryer for peanut snack automatic peanut fryer machine processing line is developed after combined of advanced technology at home and abroad and repeated experiments. Now the machinery of the commercial deep fryer for peanut snack automatic peanut fryer machine processing line has been exported to singapore, canada, brazil, and western europe, and other countries and regions, promoting the development of the local economy.

| Customer Cases For Automatic Peanut Fryer Machine For Factory In 2021 | |

| 1 | 800kg/h CE certificated industrial energy efficient equipment snack frying automatic frying machines full automatic doritos equipment fried snack food bugle chips frying machine sold in Russia |

| 2 | 1t/h tunnel type school namkeen frying gas heated namkeen fried finger potato chips stick frying french fries machine batch fryer for sale in puerto rico |

| 3 | 500kg/h hot selling multi function electric deep frier potato fryer machine for restaurant frying equipment in bolivia |

| 4 | Senegal 1t/h ce approved commercial deep fryer for peanut snack automatic peanut fryer machine processing line |

| 5 | 1t/h energy saving large ce approved potato chips fryer machine snacks frying french fries deep fryer for sale in côte d'ivoire |

| 6 | China 300kg/h industrial equipment in burger king french fries chicken conveyor belt continuous deep fryer machine |

| Customer Case Of Commercial Deep Fryer For Peanut Snack Plant In 2021 | |

| 1 | 600kg/h industrial tunnel belt conveyor microwave paper powder tea herbs leaves nut spice grain sterilization dryer drying machine in uzbekistan |

| 2 | 500kg/h industry continuous belt frying machine frying potato chips machine fried chicken equipment in senegal |

| 3 | Mozambique 1t/h continuous nut frying machine low price professional automatic fryer fried peanut production line |

| 4 | Bangladesh 800kg/h fully continue equipment frying ly-1800c automatic continue food processing equipment vacuum frying machine for sale |

| 5 | 1t/h thai frying continuous frying machine commercial fryer pressure snack continuous frying machine |

| 6 | Uzbekistan 1t/h frying industrial frying machine full automatic 300-500kg/h industry large fried potato chips fried french fries continuous frying machine |

| 7 | Usa 600kg/h industrial equipment in burger king french fries chicken conveyor belt continuous deep fryer machine |

| 8 | 500kg/h Indonesia shrimp slices continuous frying machine automatic fryer |