The Ultimate Guide to hard biscuit machine in 2024

Introduction

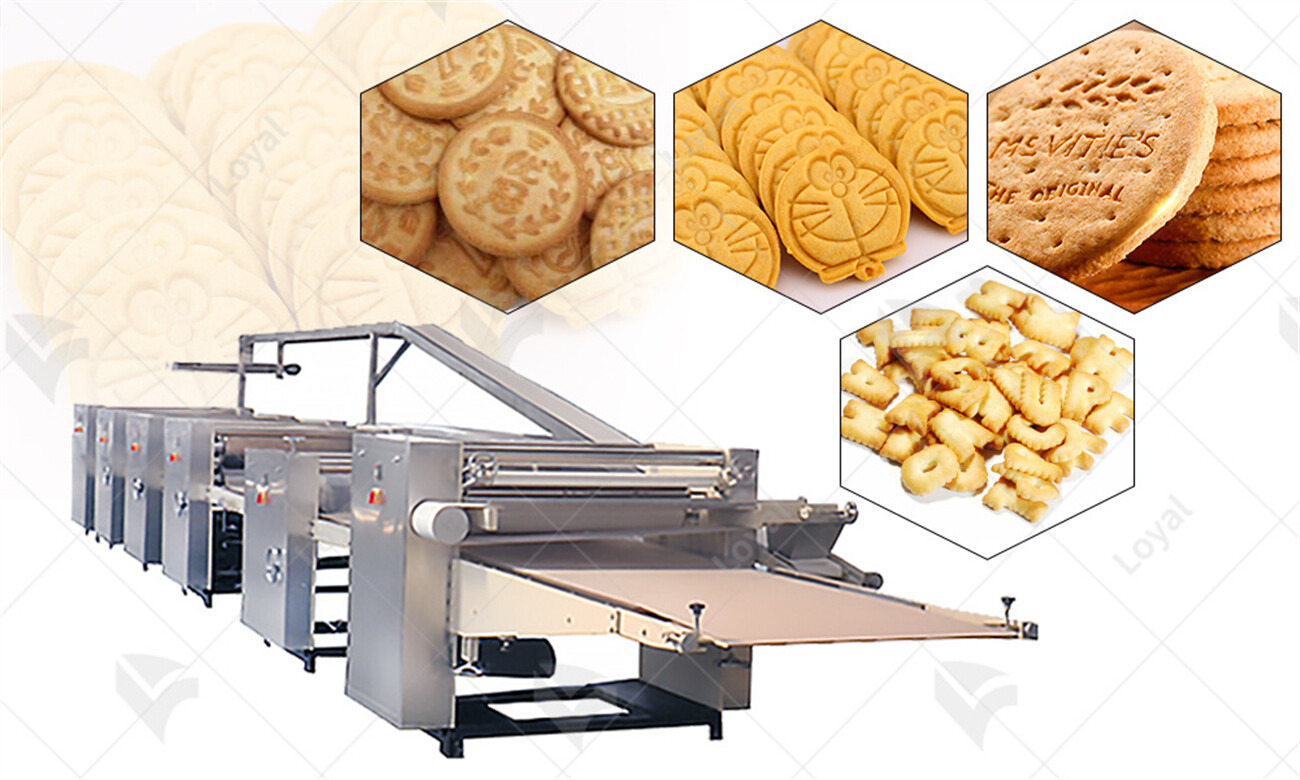

The hard biscuit machine is a cornerstone of the industrial baking industry, playing a crucial role in the mass production of a diverse range of biscuits. As we progress into 2024, the capabilities and efficiency of these machines have become even more significant, with technological advancements pushing the boundaries of what's possible in biscuit manufacturing.

The hard biscuit machine is designed to automate the entire process of biscuit production, from dough mixing to baking and cooling. This automation not only increases the speed and volume of production but also ensures a high level of uniformity and quality in the final product. In this guide, we will explore the various aspects of modern hard biscuit machines, from their key features to the latest technological innovations and their impact on the future of biscuit production.

Stay tuned as we delve into the world of hard biscuit machines in 2024 and discover how these machines are revolutionizing the way we produce one of the world's most beloved snacks.

Key Features of a Modern Hard Biscuit Machine

A modern hard biscuit machine is a sophisticated piece of equipment that incorporates several key features to streamline the biscuit-making process. Here's what you can expect from today's advanced biscuit machinery:

1. Dough Handling Systems: Modern machines feature advanced dough handling systems that ensure consistent dough texture and weight, critical for the quality and uniformity of the biscuits.

2. Forming and Cutting Technology: Precise forming and cutting mechanisms allow for a variety of biscuit shapes and sizes, with minimal waste and high accuracy.

3. High-Speed Baking Chambers: The baking chambers in these machines are designed for high-speed operation, with accurate temperature control for perfect baking results every time.

4. Energy-Efficient Design: Newer models of hard biscuit machines are built with energy efficiency in mind, reducing operational costs and environmental impact.

5. Automated Cooling Lines: After baking, biscuits need to cool quickly and evenly. Automated cooling lines help achieve this, preparing the biscuits for packaging without compromising their texture.

6. Sanitary Construction: Easy-to-clean surfaces and enclosed systems prevent cross-contamination and ensure the machine meets high standards of hygiene.

7. Programmable Logic Controllers (PLCs): These computers automate and control the machine's operations, allowing for precise adjustments and monitoring of the biscuit-making process.

8. Flexible Production Capacity: Modern machines can be adjusted to produce different quantities, allowing manufacturers to scale up or down based on demand.

9. Minimal Downtime: Designed with durability and reliability in mind, these machines are built to minimize downtime and maximize production time.

10. Safety Features: Safety interlocks, emergency stop buttons, and other features ensure that operating the hard biscuit machine is as safe as possible.

These features not only make the hard biscuit machine an efficient workhorse in the biscuit factory but also a testament to the technological advancements that are shaping the future of the baking industry. As the demand for high-quality, mass-produced biscuits continues to grow, the role of these machines becomes more critical than ever.

Technological Innovations in 2024 Models

The hard biscuit machine is at the forefront of technological innovation in the food processing industry. Here's how the latest models are leveraging technology to improve biscuit production:

1. Automation: Full automation from dough preparation to baking and cooling reduces manual labor and increases efficiency.

2. Computer-Controlled Systems: Modern machines use computer systems to control the entire process, allowing for precise adjustments and consistent quality.

3. Energy-Efficient Technologies: Newer models incorporate energy-saving features to reduce operational costs and environmental impact.

4. Internet of Things (IoT): IoT integration allows for remote monitoring and control, predictive maintenance, and real-time data analysis.

5. Customization Capabilities: Advanced machines can produce a wide range of biscuit types, sizes, and shapes to meet diverse consumer preferences.

6. Safety Features: Modern safety features, such as emergency stop functions and safety guards, ensure a secure operating environment

7. Sustainability: Eco-friendly designs and processes minimize waste and maximize the use of resources.

8. User-Friendly Interfaces: Intuitive control panels and touchscreens make it easy for operators to manage the machine.

These innovations are transforming the hard biscuit machine into a highly efficient, reliable, and sustainable solution for large-scale biscuit production. As technology continues to evolve, these machines are set to become even more advanced, further enhancing the future of biscuit manufacturing.

Impact on Productivity and Efficiency

The integration of hard biscuit machines into the production process has a profound impact on the efficiency and productivity of biscuit manufacturing:

1. Increased Output: Automated machines can produce biscuits at a much higher rate than manual methods, meeting the demand for mass production.

2. Uniform Quality: Consistent dough preparation and baking processes ensure that every biscuit meets the same high standards, enhancing product quality.

3. Reduced Labor Costs: By automating repetitive tasks, hard biscuit machines reduce reliance on manual labor, lowering labor costs and minimizing the potential for human error.

4. Energy Efficiency: Modern machines are designed to be energy efficient, which not only lowers operational costs but also contributes to environmental sustainability.

5. Scalability: The production capacity of these machines can be adjusted to match market demand, allowing for scalability and flexibility in production.

6. Quick Changeovers: Easy-to-adjust settings enable manufacturers to switch between different biscuit types with minimal downtime.

7. Consistent Size and Shape: Precise cutting and forming mechanisms produce uniformly sized and shaped biscuits, which is important for portion control and presentation.

8. Extended Shelf Life: Proper baking and cooling processes contribute to a longer shelf life for the biscuits, reducing waste from spoilage.

The use of hard biscuit machines has revolutionized the biscuit industry by streamlining the production process and ensuring a consistent, high-quality product at a scale that meets the needs of a global market.

Sustainability and Eco-Friendly Practices

The role of hard biscuit machines in promoting sustainability and eco-friendly practices within the food industry is becoming increasingly significant. Here's how these machines are contributing to a greener future:

1. Energy-Efficient Operations: Modern hard biscuit machines are designed with energy-saving technologies that reduce power consumption during the production process.

2. Waste Minimization: Precise cutting and forming mechanisms result in less dough waste, as every piece of dough is efficiently utilized.

3. Water Conservation: Many machines are engineered to use less water in the cleaning and cooling processes, contributing to water conservation efforts.

4. Durable Construction: Built with long-lasting materials, these machines are made to endure extensive use, reducing the need for frequent replacements and the associated waste.

5. Recyclable Materials: Where possible, hard biscuit machines use recyclable materials in their construction, and promote the use of recyclable packaging for the finished products.

6. Reduced Emissions: By optimizing the baking process, these machines help to reduce greenhouse gas emissions compared to less efficient baking methods.

7. Sustainable Supply Chain: Companies using hard biscuit machines can more easily source ingredients from local suppliers, reducing the carbon footprint associated with transportation.

8. Clean Production: The automated nature of these machines results in a cleaner production process with fewer opportunities for contamination or spoilage.

9. Certification and Compliance: Many manufacturers of hard biscuit machines seek certifications for their sustainability practices, demonstrating a commitment to environmental responsibility.

10. Education and Awareness: As part of their commitment to sustainability, companies often educate their staff and customers about the importance of eco-friendly practices in the food industry.

By embracing these practices, hard biscuit machines are helping the food industry move towards a more sustainable model of production, reducing its environmental impact while still meeting the needs of consumers for high-quality biscuits.

Maintenance and Operational Best Practices

Proper maintenance and operational practices are crucial for the longevity and optimal performance of hard biscuit machines. Here are some best practices to ensure these machines serve their purpose effectively and efficiently:

1. Regular Inspections: Conduct routine inspections to check for signs of wear and tear, ensuring that all components are functioning as intended.

2. Preventive Maintenance: Implement a preventive maintenance schedule that includes tasks such as oiling moving parts, replacing worn belts, and checking electrical connections.

3. Cleaning and Sanitization: Clean the machine thoroughly after each production run to prevent the buildup of dough residue, which can affect the taste and quality of biscuits and lead to hygiene issues.

4. Operator Training: Train operators on how to use the machine correctly, perform basic maintenance tasks, and respond to common operational issues.

5. Spare Parts Inventory: Keep a stock of common wear-and-tear parts on hand to facilitate quick repairs and minimize downtime.

6. Calibration: Regularly calibrate the machine to ensure that it maintains the correct measurements for dough size, thickness, and baking temperature.

7. Software Updates: If the machine is equipped with a control system or computer, keep the software up to date to ensure optimal performance and security.

8. Safety Compliance: Ensure that all safety features, such as emergency stop buttons and guards, are functioning correctly and that operators are trained in safe machine operation.

9. Energy Efficiency: Monitor the machine's energy consumption and make adjustments as needed to optimize efficiency, such as adjusting baking times or temperatures.

10. Documentation: Keep detailed records of all maintenance and repair work, as well as the machine's performance metrics, to identify patterns and anticipate future maintenance needs.

By following these best practices, manufacturers can extend the life of their hard biscuit machines, reduce operational costs, and ensure a consistent supply of high-quality biscuits. Proper maintenance also helps to prevent unexpected downtime, which can be costly and disruptive to the production schedule.

Regulatory Compliance in the Biscuit Industry

In the biscuit industry, regulatory compliance is not just a box-ticking exercise; it's a fundamental aspect of ensuring public safety, maintaining industry standards, and building consumer trust. Here's how hard biscuit machines factor into this critical area:

1. Food Safety Standards: Hard biscuit machines must be designed and operated in accordance with food safety regulations to prevent contamination and ensure the production of safe, high-quality biscuits.

2. Machine Safety: The machines should include safety features such as guards to protect operators from moving parts, emergency stop buttons, and interlock systems that stop the machine when opened.

3. Cleanliness and Sanitation: Compliance includes maintaining a clean and sanitary environment. Machines should be easy to clean and designed to prevent the harboring of bacteria or pests.

4. Traceability: Modern machines often include features that support traceability, allowing manufacturers to track ingredients and products throughout the supply chain.

5. Energy and Environmental Regulations: With a growing focus on sustainability, there may be regulations around energy use and environmental impact that hard biscuit machines need to comply with.

6. Product Labeling: Machines should support the accurate labeling of products with information on ingredients, allergens, and nutritional content.

7. Quality Control: Regular quality control checks are part of compliance, ensuring that the biscuits produced meet the required standards for quality and safety.

8. Regulatory Audits: Be prepared for and participate in regulatory audits, which are designed to ensure ongoing compliance with industry standards.

9. Staff Training: Ensure that all staff are trained in the regulations relevant to biscuit production and are aware of their roles in maintaining compliance.

10. Documentation and Record Keeping: Maintain thorough documentation and records of all machine operations, maintenance, and any incidents or corrective actions taken.

By adhering to these regulatory compliance measures, manufacturers using hard biscuit machines can contribute to a safe and trustworthy biscuit industry, ensuring the well-being of consumers and the reputation of the business.

Regulatory Compliance in the Biscuit Industry

In the biscuit industry, regulatory compliance is not just a box-ticking exercise; it's a fundamental aspect of ensuring public safety, maintaining industry standards, and building consumer trust. Here's how hard biscuit machines factor into this critical area:

1. Food Safety Standards: Hard biscuit machines must be designed and operated in accordance with food safety regulations to prevent contamination and ensure the production of safe, high-quality biscuits.

2. Machine Safety: The machines should include safety features such as guards to protect operators from moving parts, emergency stop buttons, and interlock systems that stop the machine when opened.

3. Cleanliness and Sanitation: Compliance includes maintaining a clean and sanitary environment. Machines should be easy to clean and designed to prevent the harboring of bacteria or pests.

4. Traceability: Modern machines often include features that support traceability, allowing manufacturers to track ingredients and products throughout the supply chain.

5. Energy and Environmental Regulations: With a growing focus on sustainability, there may be regulations around energy use and environmental impact that hard biscuit machines need to comply with.

6. Product Labeling: Machines should support the accurate labeling of products with information on ingredients, allergens, and nutritional content.

7. Quality Control: Regular quality control checks are part of compliance, ensuring that the biscuits produced meet the required standards for quality and safety.

8. Regulatory Audits: Be prepared for and participate in regulatory audits, which are designed to ensure ongoing compliance with industry standards.

9. Staff Training: Ensure that all staff are trained in the regulations relevant to biscuit production and are aware of their roles in maintaining compliance.

10. Documentation and Record Keeping: Maintain thorough documentation and records of all machine operations, maintenance, and any incidents or corrective actions taken.

By adhering to these regulatory compliance measures, manufacturers using hard biscuit machines can contribute to a safe and trustworthy biscuit industry, ensuring the well-being of consumers and the reputation of the business.

Future of Hard Biscuit Machine Technology

As we look ahead, the future of hard biscuit machine technology is set to bring about transformative changes in the biscuit manufacturing industry:

1. Advanced Automation: Future machines will likely feature even higher levels of automation, with robotics and AI playing a more prominent role in the production process.

2. Sustainability: There will be a continued focus on sustainability, with machines designed to minimize energy and water usage and maximize the use of eco-friendly materials.

3. Customization: Machines will become more versatile, allowing for a wider range of biscuit types, shapes, and flavors to cater to diverse consumer preferences.

4. Health and Wellness: In response to the health-conscious market, hard biscuit machines may be adapted to produce biscuits with healthier ingredients, such as whole grains or reduced sugar.

5. Smart Technology: Integration with IoT and other smart technologies will enable better monitoring, predictive maintenance, and remote operation of machines.

6. Regulatory Adaptability: Machines will be designed to adapt to changing regulatory landscapes, ensuring ongoing compliance with international food safety and quality standards.

7. Enhanced Quality Control: Future models will likely include advanced sensors and quality control features to ensure consistent and superior biscuit quality.

8. Resource Efficiency: There will be a push towards machines that use fewer resources, produce less waste, and have a longer lifespan, contributing to a circular economy.

The hard biscuit machine is poised to become an even more integral part of the biscuit industry, driving innovation, efficiency, and sustainability in the production of these popular snacks. As technology continues to advance, these machines will play a pivotal role in shaping the future of biscuit manufacturing.

Conclusion

In conclusion, the hard biscuit machine is an indispensable piece of equipment in the modern food industry, particularly for manufacturers aiming to produce high-quality biscuits at scale. These machines are not just a reflection of technological progress but also a response to the growing consumer demand for variety, health, and sustainability in the foods they enjoy. As we have seen, hard biscuit machines are evolving to meet these demands, incorporating advanced automation, eco-friendly operations, and the flexibility to produce a wide range of biscuit types.

Looking forward, the role of these machines will only grow in importance. They will continue to shape the future of biscuit production, ensuring that this beloved snack can be enjoyed by consumers around the world while meeting the highest standards of quality, taste, and sustainability. The hard biscuit machine is more than just machinery; it is a symbol of innovation and a commitment to excellence in the food manufacturing industry.

Reference

1. Food Processing:

Website: [Food Processing](https://www.foodprocessing.com/)

2. Food Engineering:

Website: [Food Engineering](https://www.foodengineeringmag.com/)

3. Process Industry Forum:

Website: [Process Industry Forum](https://www.processindustryforum.com/)

4. Food Manufacture:

Website: [Food Manufacture](https://www.foodmanufacture.co.uk/)